35

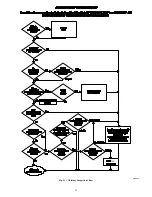

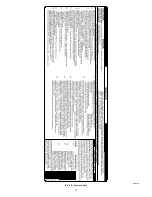

Table 17 – Gas Valve Outlet Pressure for Gas Heat Values at

Altitude -- 100,000

(Tabulated Data Based on 100,000 BTUH Input, for 0-ft (0-m)

to 5400-ft (1646-M) above sea level)

ALTITUDE

RANGE

AVG. GAS

SPECIFIC GRAVITY OF

NATURAL GAS

HEAT VALUE

0.58

0.60

0.62

0.64

AT ALTITUDE

Gas Valve Outlet Pressure

(in. W.C.)

ft (m)

(Btu/cu ft)

U.

S

.A.

900

3.3

3.4

3.5

3.6

0

925

3.1

3.2

3.3

3.4

(0)

950

2.9

3.0

3.1

3.2

975

2.8

2.9

3.0

3.1

to

1000

2.6

2.7

2.8

2.9

1025

2.5

2.6

2.7

2.8

2000

1050

2.4

2.5

2.6

2.6

(610)

1075

2.3

2.4

2.4

2.5

1100

2.2

2.3

2.3

2.4

U.

S

.A.

800

3.5

3.7

3.8

3.9

2001

825

3.3

3.4

3.6

3.7

(611)

850

3.1

3.2

3.3

3.5

875

3.0

3.1

3.2

3.3

to

900

2.8

2.9

3.0

3.1

925

2.6

2.7

2.8

2.9

3000

950

2.5

2.6

2.7

2.8

(914)

975

2.4

2.5

2.5

2.6

1000

2.3

2.3

2.4

2.5

U.

S

.A.

On

ly

775

3.5

3.6

3.7

3.8

800

3.3

3.4

3.5

3.6

3001

825

3.1

3.2

3.3

3.4

(915)

850

2.9

3.0

3.1

3.2

to

875

2.7

2.8

2.9

3.0

900

2.6

2.7

2.8

2.8

4000

925

2.4

2.5

2.6

2.7

(1219)

950

2.3

2.4

2.5

2.6

975

2.2

2.3

2.3

2.4

1000

2.1

2.2

2.2

2.3

U.

S

.A.

On

ly

750

3.4

3.5

3.7

3.8

775

3.2

3.3

3.4

3.5

4001

800

3.0

3.1

3.2

3.3

(1220)

825

2.8

2.9

3.0

3.1

850

2.7

2.8

2.9

2.9

to

875

2.5

2.6

2.7

2.8

900

2.4

2.5

2.5

2.6

5000

925

2.3

2.3

2.4

2.5

(1524)

950

2.1

2.2

2.3

2.4

975

2.0

2.1

2.2

2.2

1000

1.9

2.0

2.1

2.1

U.

S

.A.

On

ly

725

3.4

3.6

3.7

3.8

750

3.2

3.3

3.4

3.6

5001

775

3.0

3.1

3.2

3.3

(1524)

800

2.8

2.9

3.0

3.1

825

2.6

2.7

2.8

2.9

to

850

2.5

2.6

2.7

2.8

875

2.4

2.4

2.5

2.6

5400

900

2.2

2.3

2.4

2.5

(1646)

925

2.1

2.2

2.2

2.3

950

2.0

2.1

2.1

2.2

975

1.9

1.9

2.0

2.1

1000

1.8

1.9

1.9

2.0

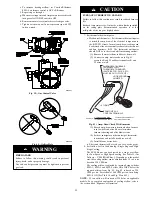

SERVICE AND MAINTENANCE

PROCEDURES

Untrained personnel can perform basic maintenance functions

such as cleaning and replacing air filters. All other operations

must be performed by trained service personnel. A qualified

service person should inspect the furnace once a year.

FIRE, INJURY, OR DEATH HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

The ability to properly perform maintenance on this

equipment requires certain knowledge, mechanical skills,

tools, and equipment. If you do not possess these, do not

attempt to perform any maintenance on this equipment

other than those procedures recommended in the User’s

Manual.

!

WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing, modifying, or servicing system, main

electrical disconnect switch must be in the OFF position and

install a lockout tag. There may be more than one

disconnect switch. Lock out and tag switch with a suitable

warning label. Verify proper operation after servicing.

!

WARNING

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in improper

furnace operation or failure of furnace.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation.

CAUTION

!

INTRODUCTION

GENERAL

These instructions are written as if the furnace is installed in an

upflow application. An upflow furnace application is where the

blower is located below the combustion and controls section of

the furnace, and conditioned air is discharged upward. Since this

furnace can be installed in any of the 4 positions shown in Fig. 4,

you must revise your orientation to component location

accordingly.

ELECTRICAL CONTROLS AND WIRING

ELECTRICAL OPERATION HAZARD

Failure to follow this warning could result in personal

injury or death.

There may be more than one electrical supply to the

furnace. Check accessories and cooling unit for additional

electrical supplies that must be shut off during furnace

servicing. Lock out and tag switch with a suitable warning

label.

!

WARNING

The electrical ground and polarity for 115--v wiring must be

properly maintained. Refer to Fig. 24 for field wiring information

and to Fig. 45 for furnace wiring information.