24

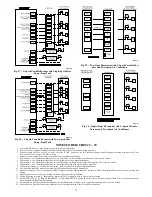

SEE NOTES: 1,2,4,7,8,9 on the page

following these figures

A03213

Fig. 34 -- Horizontal Left Application--Vent Elbow Left

SEE NOTES: 1,2,4,5,7,8,9 on the page

following these figures

A03215

Fig. 35 -- Horizontal Left Application--Vent Elbow Up

SEE NOTES: 1,2,4,7,8,9 on the page

following these figures

A03214

Fig. 36 -- Horizontal Right Application--Vent Elbow Right

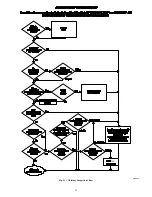

SEE NOTES: 1,2,4,5,6,7,8,9

on the page following these figures

A03207

Fig. 37 -- Downflow Application--Vent Elbow Left then Up

See NOTES following images.

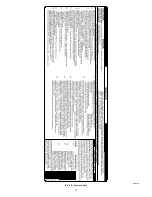

VENTING NOTES FOR FIGURES 32 -- 37

1. For common vent, vent connector sizing and vent material: United States----use the NFGC.

2. Immediately increase to 5--inch (127 mm) or 6--inch (152 mm) vent connector outside furnace casing when 5--inch (127 mm) vent connector is required, refer to Note 1

above.

3. Side outlet vent for upflow and downflow installations must use Type B vent immediately after exiting the furnace, except when factory--authorized, Downflow Vent

Guard Kit, is used in the downflow position. See Product Data Sheet for accessory listing.

4. Type--B vent where required, refer to Note 1 above.

5. Four--inch single--wall (26 ga. min.) vent must be used inside furnace casing and when the Downflow Vent Guard Kit is used external to the furnace. See Product Data

Sheet for accessory listing.

6. Factory--authorized accessory Downflow Vent Guard Kit required in downflow installations with lower vent configuration. See Product Data Sheet for accessory listing.

7. Secure vent connector to furnace elbow with (2) corrosion--resistant sheet metal screws, spaced approximately 180

_

apart.

8. Secure all other single wall vent connector joints with (3) corrosion resistant screws spaced approximately 120

_

apart.

9. Secure Type--B vent connectors per vent connector manufacturer’s recommendations.