40

PERSONAL INJURY HAZARD

Failure to follow this WARNING can result in

personal injury.

Disconnect all electrical power when servicing the fan

motor. Apply appropriate lockout/tagout procedures.

!

WARNING

3. Shut off power to the unit and install a lockout tag..

4. Disconnect the gas piping at the unit gas valve.

5. Remove the wires connected to the gas valve. Mark

each wire to assist in reconnecting power to the gas

valve.

6. Remove the igniter wires and sensor wires at the Inte-

grated Gas Unit Controller (IGC). See Fig. 55.

7. Remove the 2 screws that attach the burner rack to

the vestibule plate. See Fig. 51.

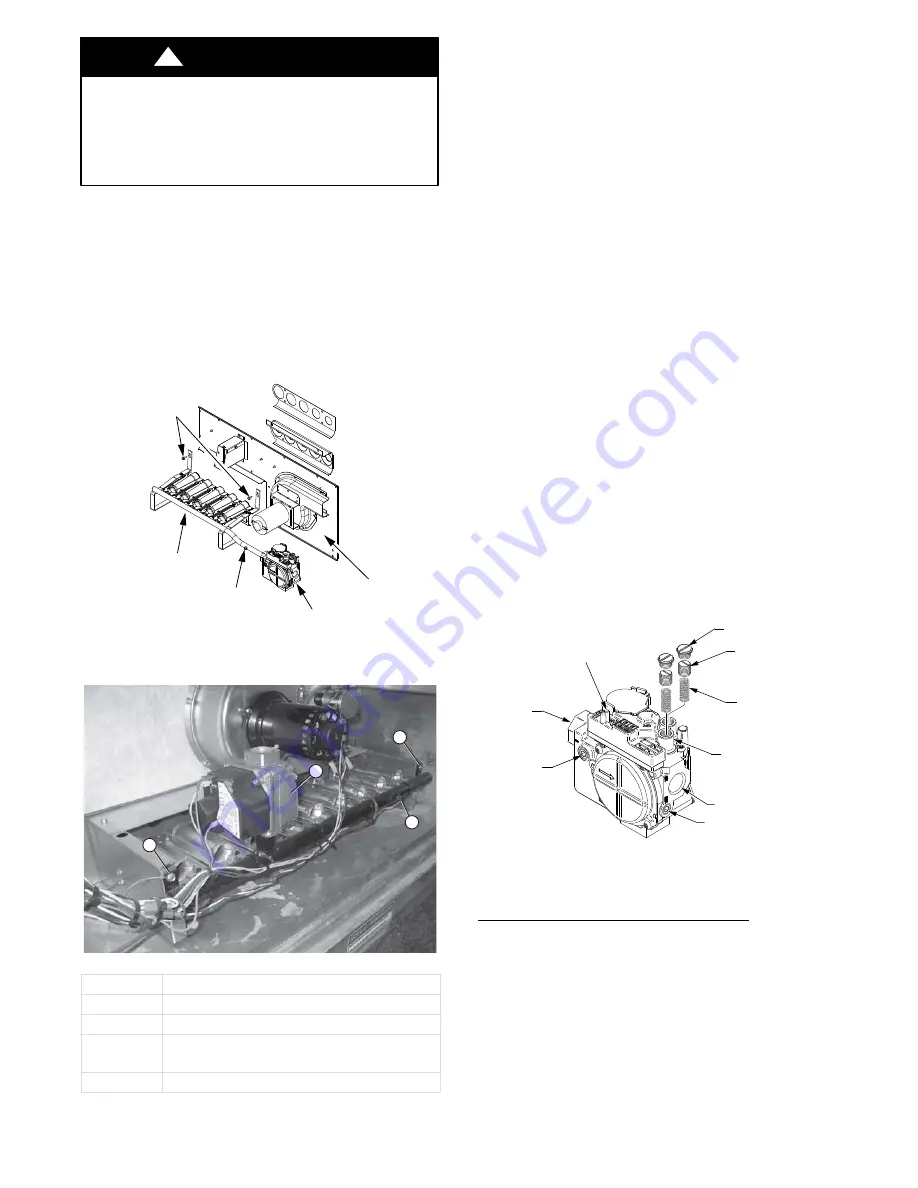

BURNER

ASSEMBLY

GAS VALVE

VESTIBULE

PLATE

SCREWS

MANIFOLD

PRESSURE TAP

~

C12594

Fig. 51

−

Burner Assembly Removal

3

2

1

1

C09395

Item No.

Description

1

Gas manifold mounting screws

(

qty 2)

2

Gas valve inlet plug

3

Propane conversion label

(apply label where indicated)

4

Gas manifold pressure tap

Fig. 52

−

Burner Tray Details

8. Slide the burner tray out of the unit (Fig. 52).

9. To reinstall, reverse the procedure outlined above.

Cleaning and Adjustment

1. Remove the burner rack from the unit as described in

the Removal and Replacement of Gas Train section.

2. Inspect the burners; if dirty, remove the burners from

rack. (Mark each burner to identify its position before

removing from the rack.)

3. Use a soft brush to clean the burners and cross

−

over

port as required.

4. Adjust the spark gap. The gap should be 0.12 – 0.14

″

(3.06 – 3.60 mm) and spaced 0.18

″

(4.60 mm) from

the end of the burner. (See Fig. 54)

5. If the factory orifice has been removed, check that

each orifice is tight at its threads into the manifold

pipe and the orifice projection does not exceed the

maximum valve. See Fig. 50.

6. Reinstall burners on rack in the same locations as

they were installed at the factory. The outside cross-

over flame regions of the outermost burners are

pinched off to prevent excessive gas flow from the

side of the burner assembly. If the pinched crossovers

are installed between two burners, the flame will not

ignite properly.

7. Reinstall the burner rack as described in the Removal

and Replacement of Gas Train section.

Gas Valve

All unit sizes are equipped with 2

−

stage gas valves. See

Fig. 53 for locations of adjustment screws and features.

PLASTIC ADJUST

SCREW (2)

REGULATOR SPRING (2)

(PROPANE - WHITE

NATURAL - SILVER)

LOW STAGE

GAS PRESSURE

REGULATOR

ADJUSTMENT

MANIFOLD

PRESSURE TAP

INLET

PRESSURE TAP

ON/OFF

SWITCH

REGULATOR

COVER SCREW (2)

NPT INLET

NPT OUTLET

C12066A

Fig. 53

−

Gas Valve

Adjusting Gas Valve Pressure Settings

IMPORTANT

: Leak check (using a mixture of soapy

water or leak detection fluid) all gas connections

including the main service connection, gas valve, gas

spuds, and manifold pipe plug. All leaks must be repaired

before firing the unit.

Summary of Contents for 581J-17-28

Page 73: ...73 APPENDIX IV WIRING DIAGRAMS cont C160042 Fig 72 581J D17 D28 Power Diagram 208 230 3 60 ...

Page 74: ...74 APPENDIX IV WIRING DIAGRAMS cont C160043 Fig 73 581J D17 D28 Power Diagram 460 3 60 ...

Page 75: ...75 APPENDIX IV WIRING DIAGRAMS cont C160044 Fig 74 581J D17 D28 Power Diagram 575 3 60 ...

Page 80: ...80 APPENDIX IV WIRING DIAGRAMS cont C160049 Fig 79 RTU OPEN Wiring Diagram ...