7

TROUBLESHOOTING THE ECM MOTOR

Axion™ Fan motors are designed with several built-in protec

-

tions included in the motor software. If the motor detects a fault

it will safely shut down. For temperature related faults the motor

requires a line voltage reset to continue operation. For all others,

the motor will resume operation automatically as soon as the

fault condition is cleared. See Table 2 for a complete list.

Table 2 — Fault Condition/Reset Trigger

Troubleshooting the motor requires a voltmeter.

1. Disconnect main power to the unit.

2. Disconnect motor plug in supply section of the unit.

3. Restore main unit power.

4. Check for proper line voltage at motor power leads Black

(PL1-1), Yellow (PL1-2), and Blue (PL-3). Blue is only

present on 3-phase motors. See the following table.

5. Disconnect main power.

6. Reconnect motor plug in supply section of unit.

7. Restore main power.

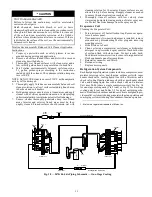

8. Check for proper motor control voltage signal of 9.7Vdc

to 10.3Vdc at IFM-1 and IFM-3 on Unit Control Board

(UCB). See Fig. 9.

9. Using a jumper wire from unit control terminals R to G,

engage motor operation.

10. Verify control signal from user speed selection switch by

placing voltmeter taps in provided terminals marked Vdc.

Signal should be between 3.8Vdc and 10.3Vdc.

11. If the motor does not start and run, remove the fan assem

-

bly and replace the motor with one having the same part

number. Do not substitute with an alternate design motor

as the voltage/speed programming will not be the same as

that on an original factory motor.

Removing the Motor and Fan Assembly

NOTE: Due to press fit design of composite Rotor on Motor, it is

highly recommended that any time a motor is replaced the fan

rotor is replaced as well. The rest of the assembly may be reused.

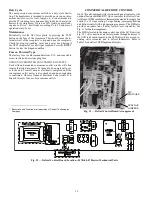

See Fig. 10.

1. Unplug motor harness from control box harness and cut

wire tie at the fan deck.

2. Unplug connectors from stator temperature limit switch.

3. Remove two screws at front of stator on fan deck.

4. Slide fan assembly forward a couple of inches to clear rear

brackets and lift assembly out.

Fig. 9 — Supply Fan Control Wiring Diagram

Fig. 10 — Fan Assembly Removal

Disassembling Motor and Fan Assembly

See Fig. 11.

1. Remove six screws from retaining rings in the top of the

fan rotor.

2. Remove rotor from motor.

3. Remove four screws connecting motor to stator flange.

4. Remove stator from motor.

Fault

Condition

Reset

Trigger

Description

Phase Failure

Automatic

One phase is missing or imbalanced. In

this case the motor will come to a stop

and then automatically restart when all

phases are present.

Locked/ Blocked

Rotor

Automatic

The rotor is blocked. Once the locking

mechanism has been removed, the

motor will automatically restart.

Motor Over

Heated

Manual

The motor will stop in the event the

motor over heats. In this case there has

to be a manual restart.

Power Module

Over Heated

Manual

The motor will stop in the event the

electronics over heat. In this case there

has to be a manual restart.

Line under-

voltage

Automatic

Once the line voltage returns within

permitted operating range, the fan will

automatically restart.

Communication

Error

Automatic

Internal communication error of the

fan’s electronics. The fan will restart

automatically, if error is cleared.

547KUnit Voltage

Motor Voltage

Min-Max Volts

208/230

230

190-250

460

230

210-250

575

460

420-500

4

2

1

3