18

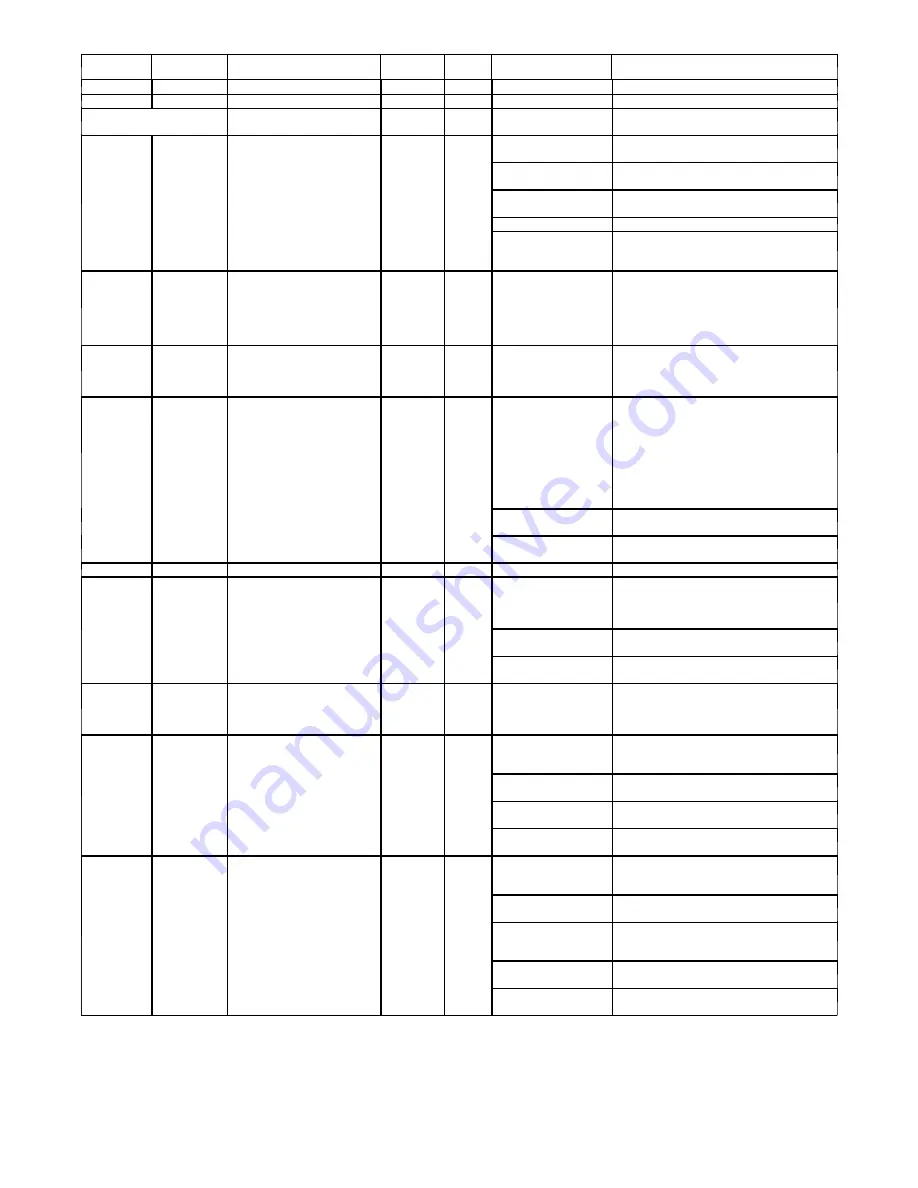

Table 6—Fault Code Actions

Flash

Code

Type

Amber LED Description

Reset

Time

Mode

Possible Causes

Actions

ON, no flash

Standby

1, pause

Variable Capacity

1 (2 sec ON), longer pause

(1 second OFF)

Variable Capacity

(Range Cutback)

25

System Mal-

function

INVALID MODEL

PLUG/INVERTER SIZE

NA

Both

Wrong Model Plug In-

stalled

Verify correct model plug installed

Damaged Model Plug

Check model plug for corrosion or breakage;

replace if necessary

Missing model plug on

service board

Re-install original model plug

Damaged AOC control

Replace AOC control

Incorrect Model Plug

with Inverter Size

Replace plug or inverter with correct size (If

model plug is for 2 Ton but Inverter is 3 Ton,

fault code 25 will be shown)

31

Local

HIGH PRESSURE SWITCH

OPEN

(stage/speed down for each

occurrence, elevates to fault

code 84 when it occurs while

running on the lowest stage)

6 Minutes

(then re-

duced

stage oper-

ation)

Both

High Pressure Event

System will self-mitigate by reducing the stage,

persistent conditions will lead to lockout (refer

to Error Code 84). 2 hours of accumulated

operation without further fault will reset fault

reduced stage operation.

32

Local

LOW PRESSURE TRIP

(elevates to fault code 83 after

3 occurrences)

6 Minutes

Both

Low Pressure Event

System will self-mitigate, persistent conditions

will lead to lockout (refer to Error Code 83) 2

hours of accumulated operation without further

fault will reset fault counter

33

Local

LOST INVERTER COMMUNI-

CATIONS

(Occurs aftr 2 minutes of no

communications between AOC

and MOC)

(Elevates to fault code 48 after

3 consecutive failures within 20

minute or 20 minutes continu-

ous loss of connection)

NA

Both

Loose or disconnected

harness (Hardness be-

tween AOC (PL20) and

MOC)

Verify good harness connection

Radio or Electrical noise

System will try to self-mitigate with repeated

start attempts

Possible damage to in-

verter

change out the Inverter drive

46

Local

BROWNOUT EVENT

6 Minutes

Both

low line voltages

if persistent contact power provider

48

System

Malfunction

LOST INVERTER COMMUNI-

CATIONS

(Elevated from fault code 33 af-

ter 3 occurrences)

NA

Both

Loose or disconnected

harness (Hardness be-

tween AOC (PL20) and

MOC)

Verify good harness connection

Radio or Electrical noise

System will try to self-mitigate with repeated

start attempts

Possible damage to in-

verter

change out the Inverter drive

49

Local

COMPRESSOR OVER CUR-

RENT FAULT

(Elevates to fault code 95 after

5 occurrences)

6 Minutes

Both

Refer to fault code 95

Refer to fault code 95

53

Fault

OUTDOOR AIR TEMP

SENSOR FAULT

NA

Both

Sensor Harness not

connected to AOC con-

trol

Ensure plug is connected to AOC control

Broken or loose har-

ness wire

Check harness for continuity; see resistance

chart to check resistance at given temperature

Broken or Damaged

Sensor

Check harness for continuity; see resistance

chart to check resistance at given temperature

Hardware damage to

AOC control

Replace AOC control

54

Fault

SUCTION TEMP SENSOR

FAULT

NA

Both

Sensor Harness not

connected to AOC

control

Ensure plug is connected to AOC control

Broken or loose

harness wire

Check harness for continuity; see resistance

chart to check resistance at given temperature

Suction Thermistor not

properly attached or in

wrong location

Ensure Sensor is properly attached to the ac-

cumulator entry-tube

Broken or Damaged

Sensor

Check harness for continuity; see resistance

chart to check resistance at given temperature

Hardware damage to

AOC control

Replace AOC control

Summary of Contents for 189BNV EVOLUTION

Page 17: ...17 Fig 38 Fault Code Label ...