8

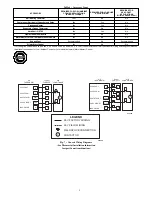

3--Phase Monitor

In 3--phase units a small circuit board is factory installed to monitor

line voltage. A small led will flash if a phase problem exists. See

code descriptions on monitor. If LED is flashing, disconnect

power to unit and interchange 2 field--wiring leads on unit

contactor.

A00010

Fig. 6 -- 3--Phase Monitor Control

(Applies to 3--Phase Units Only)

Table 5 – Three--Phase Monitor LED Indicators

LED

STATUS

OFF

No call for compressor operation

FLASHING

Reversed phase

ON

Normal

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Ensure compressor rotation is correct.

S

3--phase scroll compressors are rotation sensitive.

S

A flash LED on phase monitor indicates reverse rotation.

(See Table

5

)

This will not allow contractor to be energized.

S

Disconnect power to unit and interchange 2 field--wiring

leads on unit contactor.

CAUTION

!

Sequence of Operation

Turn on power to indoor and outdoor units. Transformer is

energized.

On a call for cooling, thermostat makes circuits R--Y and R--G.

Circuit R--Y energizes contactor, starting outdoor fan motor and

compressor circuit. R--G energizes indoor unit blower relay,

starting indoor blower motor on high speed.

When thermostat is satisfied, its contacts open, de--energizing

contactor and blower relay. Compressor and motors stop.

If indoor unit is equipped with a time--delay relay circuit, the

indoor blower will run an additional 90 seconds to increase system

efficiency.

Check Charge

Factory charge amount and desired subcooling are shown on unit

rating plate. Charging method is shown on information plate inside

unit. To properly check or adjust charge, conditions must be

favorable for subcooling charging. Favorable conditions exist

when the outdoor temperature is between 70

_

F and 100

_

F

(21.11

_

C and 37.78

_

C), and the indoor temperature is between

70

_

F and 80

_

F (21.11

_

C and 26.67

_

C).

Follow the procedure below:

Adjust charge by adding or removing 0.6 oz/ft of 3/8 liquid line

above or below 15ft (4.57 m) respectively.

NOTE:

For 15 ft (4.57 m) line set charge, refer to the table below.

some units may require additional charge depending on size. Find

model size in chart below, reference factory charge on unit’s rating

plate and add additional charge if there is a difference. Additional

charge will be needed for longer line sets (charge unit to nameplate

subcooling).

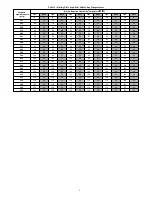

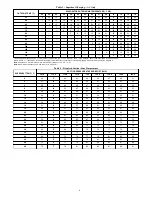

Unit

Size

15 ft. (4.57 m) Line Set Charge lb (kg)

113A

114CNA

114CNC

105A

18

4.10 (1.86)

4.77 (2.16)

4.5 (2.04)

4.87 (2.21)

24

4.22 (1.91)

4.20 (1.91)

4.20 (1.91)

4.60 (2.09)

30

4.90 (2.22)

5.67 (2.57)

5.67 (2.57)

5.67 (2.57)

36

5.00 (2.27)

5.42 (2.46)

5.42 (2.46)

6.40 (2.90)

42

6.07 (2.75)

7.90 (3.58)

7.90 (3.58)

7.46 (3.38)

48

7.00 (3.18)

8.31 (3.77)

8.31 (3.77)

8.31 (3.77)

60

8.80 (3.99)

9.39 (4.26)

9.39 (4.26)

9.39 (4.26)

For standard refrigerant line lengths (80 ft/24.38 m or less), allow

system to operate in cooling mode at least 15 minutes. If conditions

are favorable, check system charge by subcooling method. If any

adjustment is necessary, adjust charge slowly and allow system to

operate for 15 minutes to stabilize before declaring a properly

charged system.

If the indoor temperature is above 80

_

F (26.67

_

C), and the

outdoor temperature is in the favorable range, adjust system charge

by weight based on line length and allow the indoor temperature to

drop to 80

_

F (26.67

_

C) before attempting to check system charge

by subcooling method as described above.

If the indoor temperature is below 70

_

F (21.11

_

C), or the outdoor

temperature is not in the favorable range, adjust charge for line set

length above or below 15ft (4.57 m) only. Charge level should then

be appropriate for the system to achieve rated capacity. The charge

level could then be checked at another time when the both indoor

and outdoor temperatures are in a more favorable range.

NOTE

: If line length is beyond 80 ft (24.38 m) or greater than 20

ft (6.10 m) vertical separation, See Long Line Guideline for

special charging requirements.

Final Checks

IMPORTANT

: Before leaving job, be sure to do the following:

1. Ensure that all wiring is routed away from tubing and sheet

metal edges to prevent rub--through or wire pinching.

2. Ensure that all wiring and tubing is secure in unit before

adding panels and covers. Securely fasten all panels and

covers.

3. Tighten service valve stem caps to 1/12--turn past finger

tight.

4. Leave Owner’s Manual with owner. Explain system opera-

tion and periodic maintenance requirements outlined in

manual.

5. Fill out Dealer Installation Checklist and place in customer

file.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible

equipment failure, periodic maintenance must be performed on this

equipment.

Frequency of maintenance may vary depending upon geographic

areas, such as coastal applications. See Owner’s Manual for

information.