Care and Maintenance

8-3

1 —

2 —

3 —

4 —

5 —

6 —

7 —

8 —

?

!

9 —

CONTENTS

Index

5

1

2

1

2

1

▼

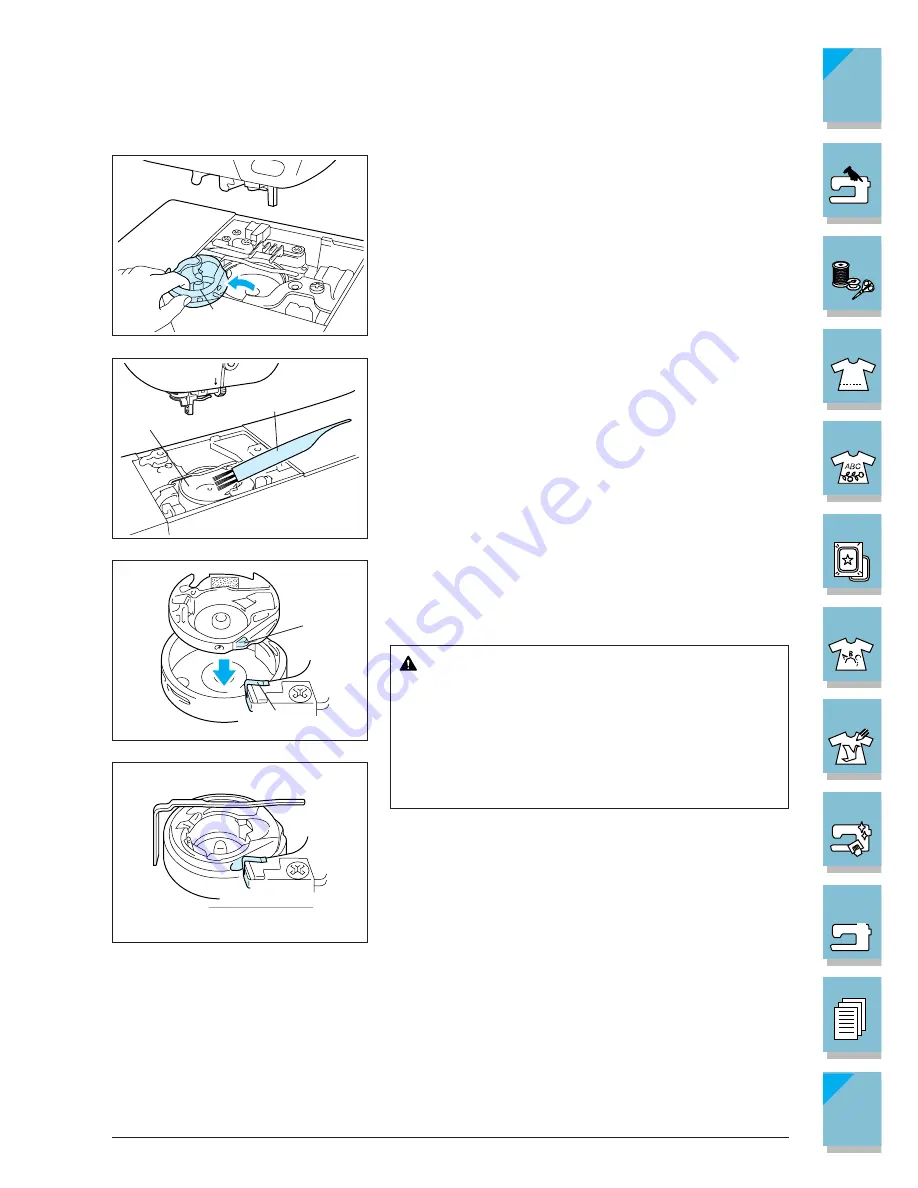

4. Remove the race.

* While pushing the race towards the back of the ma-

chine, lift the edge nearest you and remove the race.

1

Race

5. Remove accumulated lint and thread from the inner

shuttle and race with a brush or vacuum cleaner.

* Do not oil the shuttle or the race.

1

Shuttle

2

Brush

6. Check that the notch on the shuttle is in the same posi-

tion as when you removed the race. Position the race

so that the shelf and spring are aligned, and insert the

race.

CAUTION

• Do not use a damaged race or shuttle. Other-

wise, the thread may tangle and cause a poor

finish, or the needle may break. You can get

the proper parts from your authorized dealer.

• Be sure to insert the race in the correct posi-

tion. Otherwise, the needle may break.

1

Shelf

2

Spring

7. Reattach the needle plate.

Summary of Contents for ULT-2003D

Page 1: ......

Page 34: ...Setting Up 1 23 1 2 3 4 5 6 7 8 9 CONTENTS Index Contents of Other Categories ...

Page 57: ...1 46 Setting Up 1 2 3 4 5 6 7 8 9 CONTENTS Index ...

Page 168: ...Sewing Character Decorative Stitches 4 25 1 2 3 4 5 6 7 8 9 CONTENTS Index More Examples ...

Page 293: ...7 16 My Custom Stitch 1 2 3 4 5 6 7 8 9 CONTENTS Index ...

Page 313: ...9 16 Troubleshooting 1 2 3 4 5 6 7 8 9 CONTENTS Index ...

Page 315: ...A 2 Appendix 1 2 3 4 5 6 7 8 9 CONTENTS Index ...

Page 321: ...ENGLISH 114 230 XC3200 001 0205 Printed in Japan ...