6-43

Reassembling Notes

• When placing the air pump & motor module onto the ink cartridge support base, make sure that

the air tube (blue) is not bent.

• When setting the cover spring into place, take care not to pull it out of shape by extending it too

much.

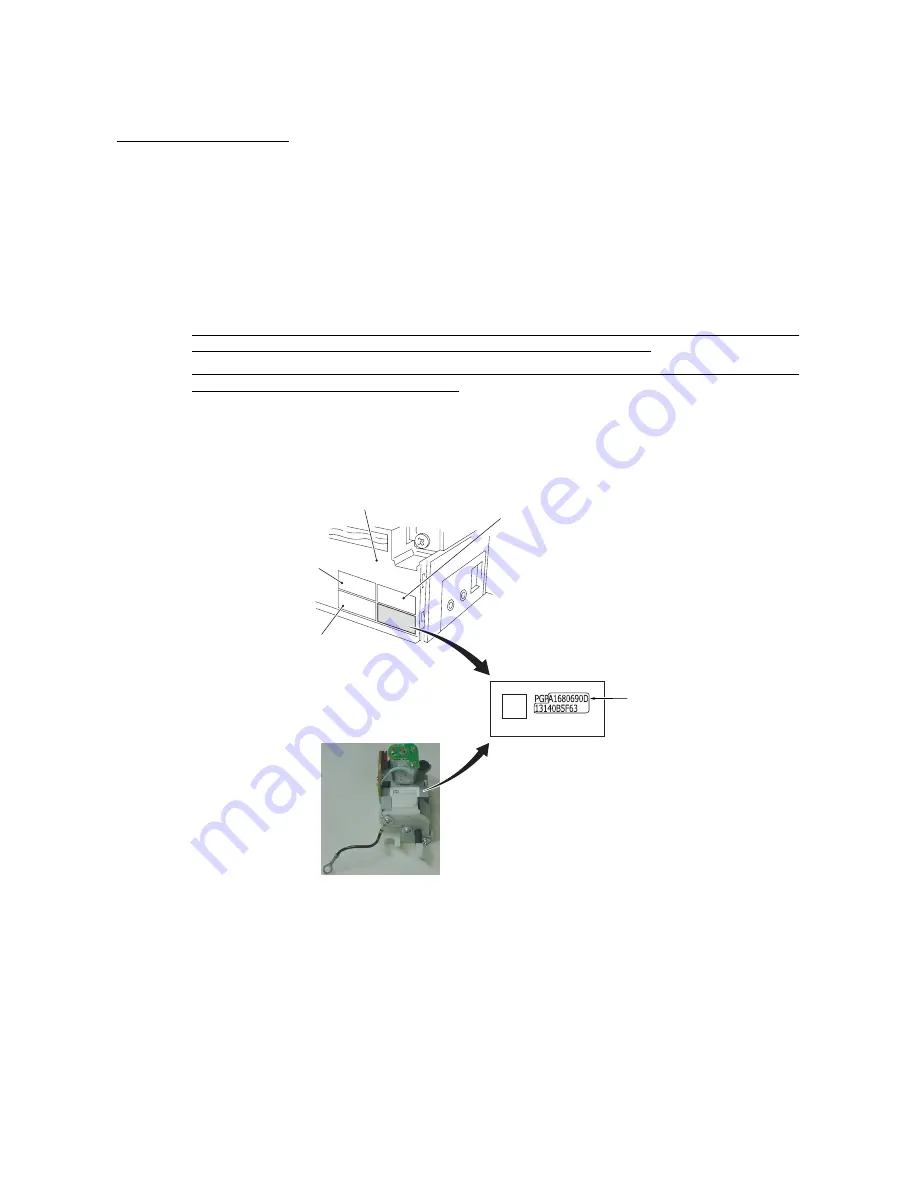

• Like the print head unit, each air pump & motor module is assigned a property code that

represents the properties unique to that module. A property label, on which a property code is

printed, is attached to the module itself and to the rear left side of the machine (with the battery

cover* or rear cover S** removed). (*For the MFC4820C, **For the MFC4420C. Refer to

Section 6.1.4.)

If you remove the air pump & motor module and store it separately from the machine, remove

the property label from the machine and store it together with the module.

If you replace the module with a new one, attach the property label that comes with the new

module to the rear left side of the machine.

If the module is replaced with a new one, you will need to update the property data stored in the

EEPROM on the driver PCB. Make the machine enter the maintenance mode (Function code 68

+ 0789) and enter the 19 digits of the property code of the newly installed module. (For details,

refer to Chapter 7, Section 7.5.15.)

Property code

(19-digit)

Lower cover

(Rear)

For paper feed roller

For ejection roller

For print head unit

Property label for

air pump & motor module

• When you replace the ink absober box with out replaceing the driver PCB, reset the purge count

according to the following procedure.

1) Press the [Menu], [2],[8],[6]and [4] keys in this order to make the machine enter the

maintenance mode.

2) Press the [8] and [0] keys in this order. to show the equipment’s log information on LCD.

3) Press the [Fax Start] button nine times. to show the purge count on LCD.

4) Press the [2],[7],[8] and [3] keys. to reset the purge count.

5) Press the [9] key twice in the initial stage of the maintenance mode to restore the machine to the

standby state.

Summary of Contents for MFC-4820C

Page 1: ...FACSIMILE EQUIPMENT SERVICE MANUAL MODEL MFC4820C MFC4420C ...

Page 6: ...CHAPTER 1 PARTS NAMES FUNCTIONS ...

Page 13: ...CHAPTER 2 SPECIFICATIONS ...

Page 19: ...2 5 2 1 4 Environmental Conditions ...

Page 26: ...CHAPTER 3 SETTING UP OF THE MACHINE ...

Page 29: ...3 2 3 2 UNPACKING THE MACHINE The equipment consists of the following major components ...

Page 40: ...CHAPTER 4 THEORY OF OPERATION ...

Page 76: ...CHAPTER 5 ROUTINE MAINTENANCE ...

Page 84: ...CHAPTER 6 DISASSEMBLY REASSEMBLY ...

Page 114: ...6 29 6 1 11 Speaker 1 Pull the speaker and its spring out of the lower cover ...

Page 136: ...CHAPTER 7 MAINTENANCE MODE ...

Page 145: ...7 8 Scanning Compensation Data List ...

Page 160: ...7 23 1st sheet 2nd sheet Vertical Alignment Check Patterns and Head Skew Check Pattern ...

Page 162: ...7 25 Margin Check Patterns ...

Page 170: ...CHAPTER 8 ERROR INDICATION AND TROUBLESHOOTING ...

Page 197: ...MFC4820C MFC4420C Appendix 1 Serial No Descriptions ...

Page 205: ...App 2 4 Click Finish to return to Windows ...

Page 209: ...MFC4820C MFC4420C Appendix 3 EEPROM Customizing Codes ...

Page 212: ...MFC4820C MFC4420C Appendix 4 Firmware Switches WSW ...

Page 252: ...App 4 40 WSW48 to WSW50 Selector No Function Setting and Specifications 1 8 Not used ...

Page 253: ...MFC4820C MFC4420C Appendix 5 Re Packing Instructions ...

Page 255: ...App 5 2 2 Place the machine in the original box with the original packaging material ...

Page 256: ...MFC4820C MFC4420C Appendix 6 Wiring Diagram ...

Page 259: ...A Main PCB 1 5 ...

Page 260: ...A Main PCB 2 5 ...

Page 261: ...A Main PCB 3 5 ...

Page 262: ...A Main PCB 4 5 ...

Page 263: ...A Main PCB 5 5 ...

Page 264: ...B Driver PCB ...

Page 265: ...C NCU PCB ...

Page 266: ...D Control Panel PCB ...

Page 267: ...E Power Supply PCB ...