USER’S GUIDE

5–4

English: HS3 User’s Guide, Chapter 5

4. Install as many SIMMs as you need.

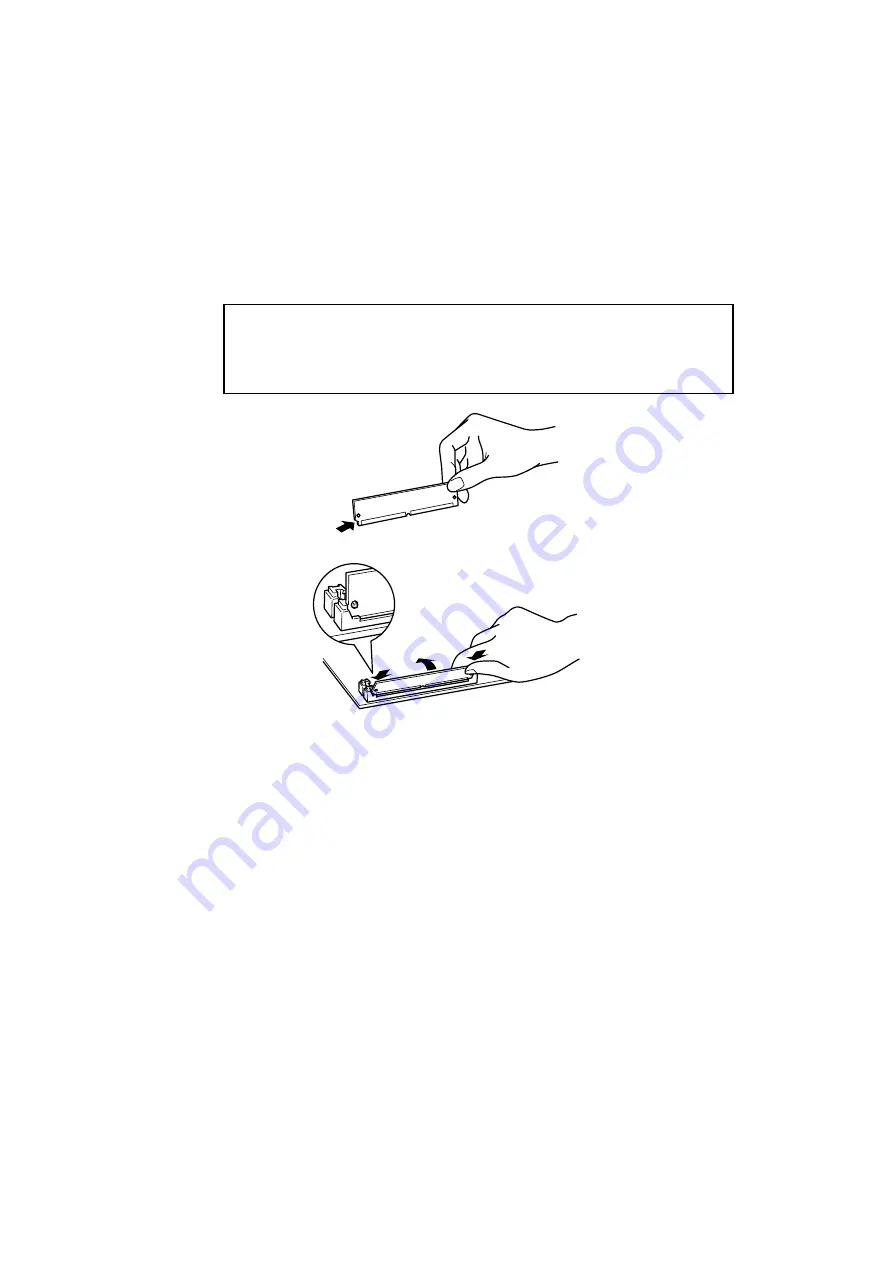

• Set the SIMM into the slot at an angle.

• Push the top of the SIMM gently towards the vertical until it clicks into

place.

✒

Notes

When installing SIMMs, be sure to install them in the order slot 1 then slot 2.

When you install different capacities of SIMMs, be sure to install the larger

capacity SIMM in slot 1 and the smaller capacity SIMM in slot 2.

Fig. 5-3 Installing the SIMMs

5. Refit the main controller board and secure it with the 5 screws.

6. Plug in the power cord and turn on the printer.

If you have installed the SIMMs incorrectly, the printer prints a report to alert

you.

Summary of Contents for HS-5000 - Color Solid Ink Printer

Page 4: ...USER S GUIDE English CS 5zxx User s Guide Preliminary TOC UD4653001 Printed in Japan ...

Page 18: ......

Page 28: ...USER S GUIDE 2 10 English HS3 User s Guide Chapter 2 ...

Page 36: ......

Page 44: ......

Page 50: ......