3-18

Confidential

■

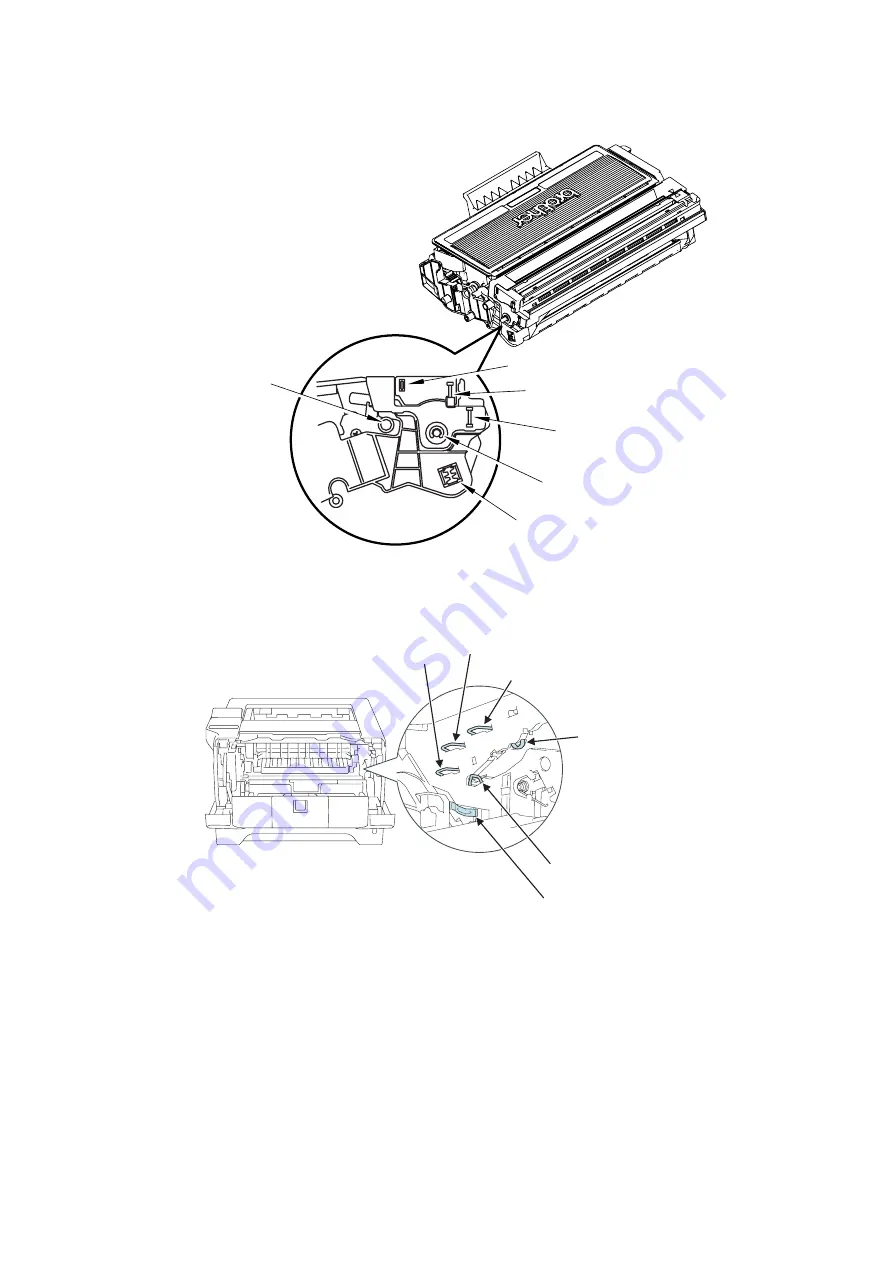

Electrodes location of the toner/drum unit

Fig. 3-2

■

Electrodes location of the machine

Fig. 3-3

<How to clean the electrodes>

Turn off the power switch. Unplug the machine from the AC power outlet, and leave the machine

for a few minutes. Then, wipe the electrodes above carefully with a dry lint-free cloth. Be

careful not to change the shapes of the electrodes.

Toner/Drum Unit

(5) Grid

(7) Cleaner

(3) Charge

(4) Developer roller

(6) Transfer roller

(1) Exposure drum

Developer roller

Charge

Grid

Cleaner

Transfer roller

Exposure drum

Summary of Contents for HL 5370DW

Page 12: ...CHAPTER 1 SPECIFICATIONS ...

Page 32: ...Confidential CHAPTER 2 THEORY OF OPERATION ...

Page 57: ...Confidential CHAPTER 3 ERROR INDICATION AND TROUBLESHOOTING ...

Page 109: ...Confidential CHAPTER 4 PERIODIC MAINTENANCE ...

Page 145: ...CHAPTER 5 DISASSEMBLY REASSEMBLY ...

Page 153: ...5 6 Confidential Fig 5 3 EM D110 4 places Separation pad ASSY ...

Page 154: ...5 7 Confidential 5 GEAR LAYOUT DRAWING Fig 5 4 ...

Page 213: ...5 66 Confidential 3 Remove the Gear 17 black Fig 5 86 4 Remove the Gear 17 white Fig 5 87 ...

Page 261: ...Confidential CHAPTER 6 ADJUSTMENTS AND UPDATING OF SETTINGS REQUIRED AFTER PARTS REPLACEMENT ...