3-5

GAS PIPING

•

The unit is equipped with a 1/2” pipe for

gas connection. Shipped with each unit,

for 3/4” gas connection, is one each of

the following:

P/N 00743 - Bushing Hex Reducer

3/4 to 1/2

P/N 01319 - Coupling 3/4 Pipe

•

3/4 NPT minimum supply piping recom-

mended.

•

Use only black steel pipe and malleable

fittings for gas connections.

•

Pressure loss in the piping must not

exceed 0.3” W.C.

•

Be sure gas supply piping is of the

proper size for the BTU input. Take into

consideration all other gas appliances

which must operate from the same gas

supply. Be sure piping will not interfere

with drain pails or valves.

•

A compound resistant to the action of

liquified petroleum gas should be used

on the threads of gas supply piping

joints. Check all connections and pipes

with a soap and water solution. Bubbles

indicate a gas leak. DO NOT use an

open flame to check for gas leaks.

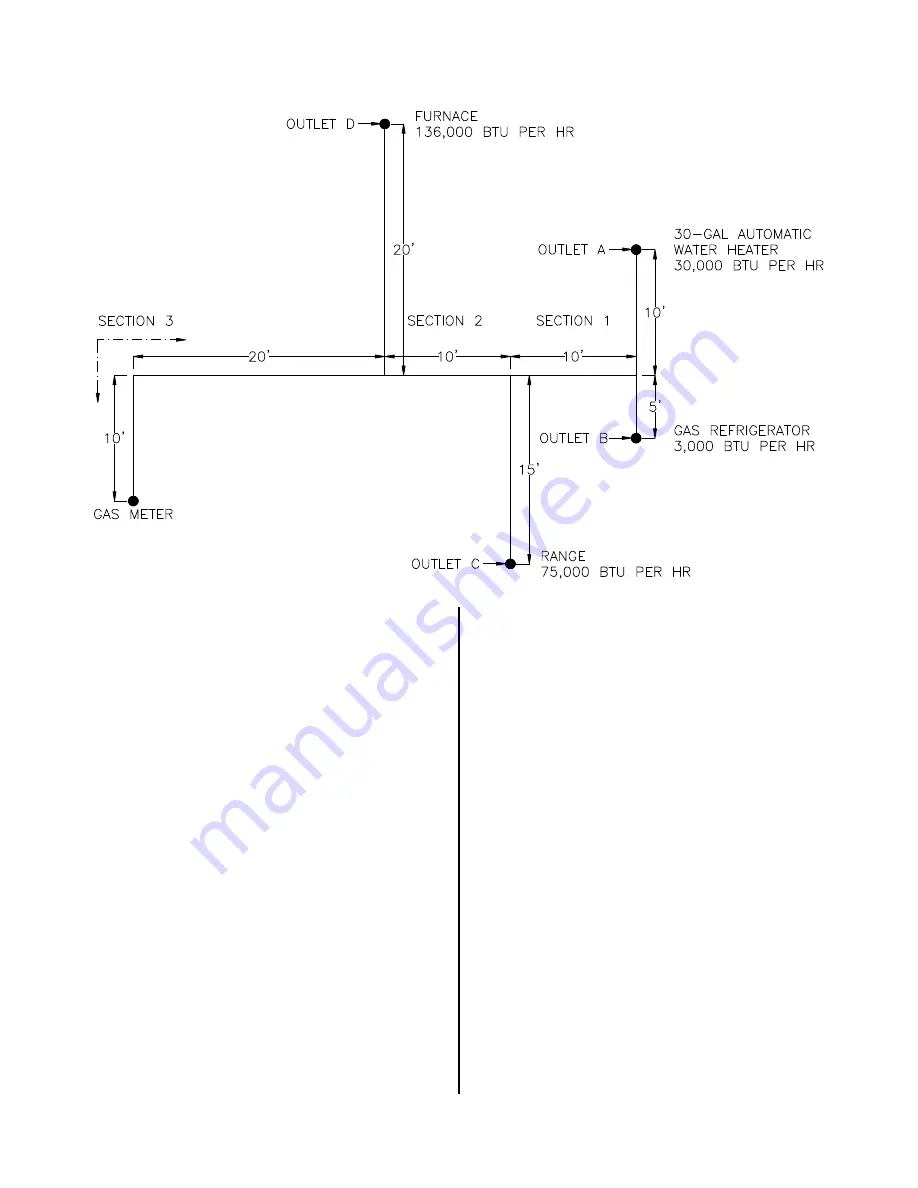

Determine the required pipe size of each

section and outlet of the piping system

shown in Solution, with a designated pres-

sure drop of 0.30 inch water column. Gas to

be used has 0.60 specific gravity and a

heating value of 1,000 BTU per cubic foot.

Example of Piping System Design:

broaster.com

Manual #17278 9/13 Rev 10/15

Summary of Contents for 2400 Series

Page 2: ......

Page 10: ...1 4 Hood Dimension In Millimeters broaster com Manual 17278 9 13 Rev 2 14 ...

Page 12: ......

Page 20: ...3 8 MODEL 2400GHCE UK broaster com Manual 17278 9 13 Rev 6 16 ...

Page 23: ...4 3 2400E 208 or 240VAC broaster com Manual 17278 9 13 Rev 9 16 ...

Page 24: ...4 4 EXPORT 2400E ST 220 380VAC to 240 415VAC broaster com Manual 17278 9 13 Rev 9 16 ...

Page 25: ...4 5 EU 2400ECE ST 230 400V broaster com Manual 17278 9 13 Rev 10 15 ...

Page 26: ......

Page 30: ......

Page 31: ......

Page 32: ...Broaster Company 2855 Cranston Road Beloit WI 53511 3991 608 365 0193 broaster com ...