53-1005235-09 Installation Guide

Brocade

®

G630 Switch Hardware Installation Guide

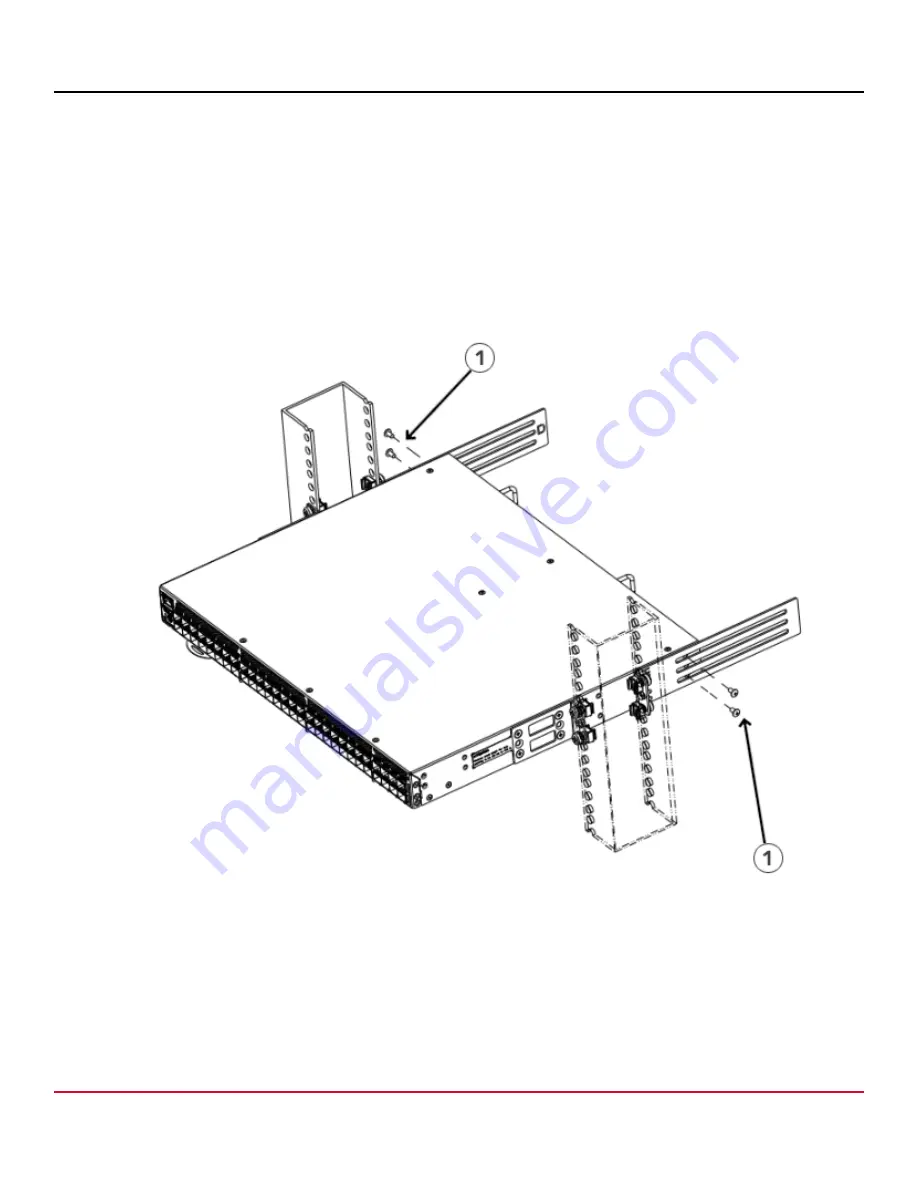

Attaching the Rear Brackets to the Device

Complete the following steps to attach the rear brackets to the device:

1. Align the right rear bracket to the right rear of the device, and use four 8-32 x 5/16-in. panhead screws to attach the

bracket to the device, as shown in the following figure. Be sure to insert the screws through the upper and lower slots

in the bracket.

2. Align the left rear bracket to the left rear of the device, and use four 8-32 x 5/16-in. panhead screws to attach the

bracket to the device. Again, use the upper and lower slots in the bracket.

3. Tighten all 8-32 x 5/16-in. screws to a torque of 17 cm-kg (15 in.-lb).

Figure 24: Attaching the Rear Brackets to the Device

1. Screws, 8-32 x 5/16-in. Panhead Phillips

53-1005235-09

48

Summary of Contents for Brocade G630-1

Page 99: ......