Ussc 17

THE FIRST FIRES

The fresh paint on your stove needs to be cured to preserve its quality. Once the fuel charge is properly ignited, only

burn small fires in your stove for the first four hours of operation. Never open the air control more than necessary to

achieve a medium burn rate.

Make sure that there’s enough air circulation while curing the stove. The odors could be smelled during the 3 or 4 first

fires. Never start your stove outside. You will not be able to see if you are over heating.

IGNITION

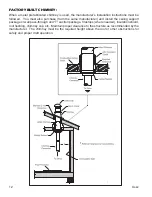

After making sure that the stove air intake controls are fully open (completely pull-out towards you), place several rumpled

sheets of paper in the centre of the combustion chamber. Place 8 to 10 pieces of small dry kindling wood over the paper

in the form of a tent. You may also place a few pieces of heating wood, but choose the smaller ones. No chemical product

should be used to light the fire.

Before igniting the paper and kindling wood, it is recommended that you warm up the chimney. This is done in order to

avoid back draft problems often due to negative pressure in the house. If such is the case, open a window slightly near

the stove and twist together a few sheets of newspaper into a torch. Light up this paper torch and hold it as close as

possible to the mouth of the pipe inside the combustion chamber to warm up the chimney. Once the updraft movement

is initiated, you are ready to ignite the stove by lighting the paper and kindling wood inside the combustion chamber.

When you have achieved a good bed of hot embers, we recommend the following burn procedures:

HEATING

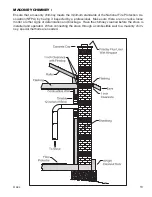

Controlled combustion is the most efficient technique for wood heating because it enables you to select the type of

combustion you want for each given situation. The wood will burn slowly if the wood stove air intake control is adjusted

to reduce the oxygen supply in the combustion chamber to a minimum. On the other hand, wood will burn quickly if

the air control is adjusted to admit a larger quantity of oxygen in the combustion chamber. The air intake control on

your stove is very simple. If you pull on it out completely towards you, it is fully open. If you push on it until it stops the

combustion air is reduced to a minimum. Real operating conditions may give very different results than those obtained

during testing according to the species of wood used, its moisture content, the size and density of the pieces, the length

of the chimney, altitude and outside temperature.

CAUTION: Never alter the damper slide or the adjustment range to increase firing for any reason. Doing so could

result in heater damage and will void your warranty.

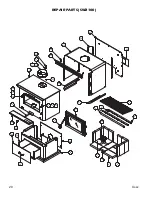

SW2100

Primary Air Settings

(Slide Damper is located in center of stove under hearth plate)

(Damper Adjustment: Pulling out on damper increases air)

Electric Blower Speed Setting

(Variable)

(Blower is on High when turned “ON”,

Rotate clock-

wise until stop for “LOW”.)

Burn Rate

Adjust Damper from fully closed

Burn Time

Blower Speed

Low

1/4” (6.3mm)

@ 30 minutes

Low

Medium - Low

3/8” (9.5mm)

@ 30 minutes

Low

Medium - High

1/2” (12.7mm)

@ 30 minutes

Low

High

approx. 3” (76mm)

all minutes

High

SW3100

Burn Rate

Adjust Damper from fully closed

Burn Time

Blower Speed

Low

1/32” (1mm)

@ 30 minutes

Low

Medium - Low

1/16” (1.5mm)

@ 30 minutes

Low

Medium - High

5/16” (8mm)

@ 30 minutes

Low

High

approx. 3” (76mm)

all minutes

High