Ussc 15

OUTSIDE COMBUSTION AIR

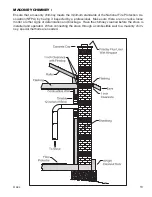

For mobile home installations, your wood stove must be have a fresh air intake installed. This type

of installation is also required in air tight houses and houses with negative pressure problems. You

can either purchase a dryer venting kit from your local hardware supply or cut a hole in the flooring

protector and home’s floor as shown in the illustration at the beginning of this manual.

Outside combustion air may be required if :

1. Your stove does not draw steadily, smoke rollout occurs, wood burns poorly, or back-drafts occur

whether or not there is combustion present.

2. Existing fuel-fired equipment in the house, such as fireplaces or other heating appliances, smell,

do not operate properly, suffer smoke roll-out when opened, or back-drafts occur whether or not

there is combustion present.

3. Opening a window slightly on a calm (windless) day alleviates any of the above symptoms.

4. The house is equipped with a well-sealed vapor barrier and tight fitting windows and/or has any

powered devices that exhaust house air.

5. There is excessive condensation on windows in the winter.

6. A ventilation system is installed in the house.

For use in MOBILE HOMES (U. S. installations ONLY):

•

WARNING! DO NOT INSTALL IN SLEEPING ROOM.

•

CAUTION! THE STRUCTURAL INTEGRITY OF THE MOBILE HOME FLOOR, WALL, AND

CEILING/ROOF MUST BE MAINTAINED.

• INSTALL IN ACCORDANCE WITH 24 CFR, PART 3280 (HUD).

• USE A FACTORY BUILT CHIMNEY THAT COMPLIES WITH UL 103 STANDARDS;

THEREFORE IT MUST BE A TYPE HT (2100°F).

• USE A SPARK ARRESTER.

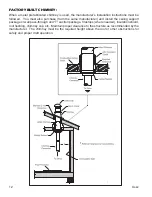

• THE STOVE MUST BE ATTACHED TO THE STRUCTURE OF THE MOBILE HOME. USE

THE TWO(2) HOLES IN THE BOTTOM OF THE HEATER’S PEDESTAL TO SECURE THE

UNIT TO THE FLOOR.

NONCOMBUSTIBLE FLOO

RING

Illustration: Securing heater to the Floor.