6 Ussc

ASSEMBLY INSTRUCTIONS

Combustion Air Intake

This appliance requires a source of combustion air. If you home is of tight construction, has negative

pressure problems or is a mobile / manufactured home, you will need an outside source of air.

You have two options. You may cut a rectangular hole in the floor of your home and the floor protector, or

purchase a standard 4” Dryer Vent kit from your local hardware supply store and install it on the rear of the

pedestal.

If your choice is to cut a rectangular hole in the floor and flooring protector, refer to the below illustrations for

assistance. You must place a rodent screen between the floor protector and the floor to prevent passage of

any unwanted vermin into your home.

If using a Dryer venting kit, the outlet cover must be of a design that DOES NOT close by means of

a flap or trap door.

You must purchase a style that allows a continuous in-flow of air and that has a rodent

screen. You will also need a Combustion Air Adapter to attach to the pedestal of the appliance. This adapter

can be purchased from your dealer.

If your home is not of tight construction or not a manufactured mobile home, you can just simply remove the

4” round knockout in the rear of the pedestal.

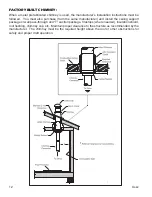

“Combustion Air thru Unit Base” installation:

First, decide the location of the appliance. Then, cut a 2” x 6” rectangular opening in the floor protector

within the appliance base’s perimeter. Using the flooring protector as a template, position it in place

and mark onto the floor of your home where to make your next cut. Make the cut in your home’s floor

slightly larger than the 2” x 6” to accommodate any misalignment. Attach a piece of screen over the

hole to prevent any unwanted vermin entering your home. Complete your appliance install.

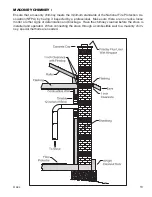

“Dryer Venting Kit” installation:

Begin by installing the 4” adapter to the rear of the appliance using the screws provided. If not already,

remove the round knock-out from the pedestal. Follow the manufacturer’s installation instructions for

attaching the dryer vent kit to the home. Then attach it to the adapter on the appliance.

“Combustion Air thru Unit Base” Installation

“Dryer Venting Kit” Installation

FLOOR PROTECTOR

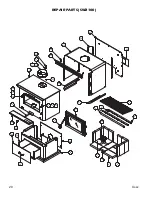

SW3100 Foot Print

SW2100 Foot Print

Home’s Floor

Rodent Screen

Non-Combustible Floor

Make a 2” x 6” (51mm x 152mm)

cutout through both the floor

protector and home’s flooring

within the perimeter of the

appliance’s base.