11

The

BRÄUNIGER

fuel flow sender is looped in the fuel line between filter and engine.

Make sure all connections of fuel line are leak proof and secure. Secure all line

connections with suitable parts, e.g. hose clamps.

The fuel flow sender is designed in such a way, that even when the sensor wheel is

blocked, there is always enough fuel throughput to keep the engine running. Of course

the fuel flow can not be measured with a blocked sensor wheel.

2.4.2 Important Safety Notes

WARNING

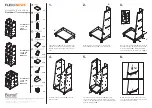

! To prevent air bubbles from getting stuck inside the fuel flow

sender, the sender

MUST

be mounted in an angle of

optimal 90°

and

minimum 60° relative to the longitudinal axis of the aircraft. Only this way a

precise measurement can be achieved. The direction of the fuel flow

MUST

be

from bottom to top

! Take care of the correct flow direction indicated by the

arrow on the sender.

WARNING!

The fuel flow sender

MUST

be mounted

AFTER

the fuel filter so

that foreign matter in the fuel cannot block the sensor wheel!

WARNING!

When mounting the fuel flow sender you

MUST

observe the safety

and operation notes of the engine manufacturer!

2.4.3 Recommendations to Achieve Precision Measurements

Because most fuel pumps create strong vibrations in the fuel line and these vibration

can negatively influence the precision of the fuel flow sender, the sender should be

mounted far away from the fuel pump.

The fuel flow sender should be mounted close to the tank. The high temperatures in

the engine compartment can change the viscosity of the fuel which can negatively

influence measurement precision!