BRAILLO

l

B 650 SF

73

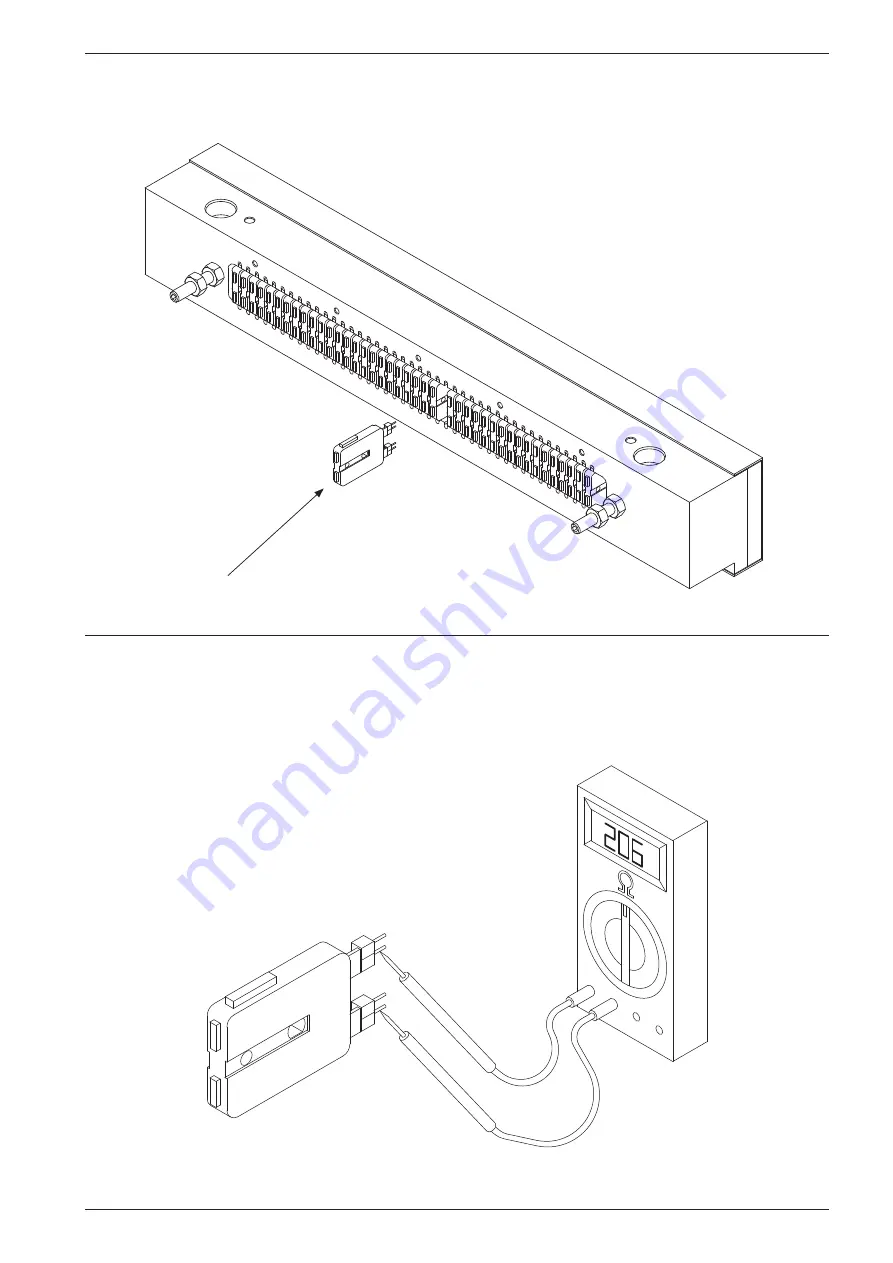

Step 2.

Pull out the defect magnet with, e.g. a narrow pair of “needle nose” pliers.

Magnet

Step 3.

Check the magnets internal resistance if you have an ohm-meter available. The resist-

ance should be between 185 ohm and 240 ohm. Any value outside this range indicates a defective

magnet.

Summary of Contents for 650 SF

Page 1: ...Rev April 2018 BRAILLO L NORWAY FOR BETTER BRAILLE AND MORE User s Guide BRAILLO 650 SF...

Page 2: ...2018 Braillo Norway AS...

Page 4: ...BRAILLO l B 650 SF 4...

Page 104: ...BRAILLO l B 650 SF 104 Frame complete...

Page 133: ...BRAILLO l B 650 SF 133 7 15 Complete schematic pneumatic...

Page 135: ...BRAILLO l B 650 SF 135 7 17 Schematic electrical 230V...

Page 137: ...BRAILLO l B 650 SF 137 7 19 Schematic PLC...

Page 139: ...BRAILLO l B 650 SF 139 7 21 Schematic sensors Picker pos Vacuum sensor...

Page 140: ...BRAILLO l B 650 SF 140 Folding ready Stackholder neg Output sensor...

Page 142: ...BRAILLO l B 650 SF 142 Door 1 switch Door 2 switch Stapling position analog sensor...

Page 143: ...BRAILLO l B 650 SF 143 7 22 Schematic staplers position 7 23 Schematic pneumatic valves...

Page 150: ...BRAILLO l B 650 SF 150 115 cm 77 cm 112 cm 8 5 Measurements All measurements in centimetres...

Page 151: ...BRAILLO l B 650 SF 151 9 GENERAL INFORMATION 9 1 Declaration of conformity...

Page 155: ...BRAILLO l B 650 SF 155...