24

POTENTIAL OPERATING PROBLEMS

1.

Arc starting difficulty. Arc interruption happens easily:

a.

Ensure the earth clamp is secured to the work piece.

b.

Check all electrical connections and ensure they are firm.

2.

The output current fails to reach rated value:

a.

The supply voltage to the machine may be lower than the stated supply. When the power

voltage is lower than rated value, the maximum output current will be lower than rated value.

3.

The current is not stable during welding:

This situation may relate to the following factors:

a.

The voltage of electric power supply changes

b.

Serious interference from electric power supply or other electric facilities.

4.

Gas vent in welds:

a.

Examine whether the gas supply hose has leaks or damage.

b.

Ensure there is adequate gas in cylinder.

c.

Examine whether there is sundries such as oil, dirt, rust, paint etc. on the surface. Clean if

necessary.

Summary of Contents for TREO 175

Page 1: ...User Manual TREO 175 ...

Page 11: ...11 Explanatory drawing for installation of TREO 175 STICK ...

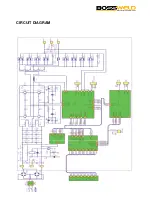

Page 22: ...22 CIRCUIT DIAGRAM ...

Page 30: ...30 Notes ...

Page 31: ...31 Notes ...