14

3.

Operation instruction under LIFT TIG mode

a. When welding stops, press the (STICK/LIFT TIG/MIG switch key) the LIFT TIG indicator lights

up, and it turns into LIFT TIG mode. LIFT TIG means the tungsten contacts the work piece first,

then press the torch switch, the arc is ignited by lifting the torch.

b. Under LIFT TIG mode, press (VRD/2T/4T switch key) to choose the welding mode:

•

2T NORMAL lighting up means 2 step control way: open the shielded gas, press the

torch switch which starts the main circuit, lift up the arc, the welding current increases

till to a steady-state value.

•

4T LATCH means 4 step control way: open the shielded gas, press the torch switch for

the first time and start the main circuit, lift up the arc and ignite it; then release the

torch switch, the machine outputs steady current. Press the torch switch for the second

time, the welding current attenuates until to crater value and keep on, then release the

torch switch again, the arc quenches soon and the welding stops.

Chart 5:

The preset current under LIFT TIG mode

c. (Multifunctional data display) shows the preset current “080A”, its unit is ampere (A).

d. Adjusting the (Multifunctional data adjusting knob) can change the welding current during welding

process, and display in (multifunctional data display). The welding current range is 10A-175A.

e. Three seconds later after setting the welding parameters, the (multifunctional data display) would

flashes for one time, which means the data has been saved. Moreover, the panel would display

these data when restart the machine next time if the parameters keep unchanged.

f. The panel displays as Chart 6 when perform welding, which means the welding voltage is 17.2V,

and the preset current is 80A.

g. Releasing the torch switch and stopping welding, the panel displays as Chart 7. “HOLD” flashes

for 3 seconds and quenched, which means the welding stops. 2 seconds later, (multifunctional

data display) redisplays the preset current.

Note:

The machine adopts touched ignition way when perform welding under TIG mode. Firstly make

sure the tungsten contacts the work piece completely, then press the torch switch, lifting up the torch to

ignite arc successfully.

Summary of Contents for TREO 175

Page 1: ...User Manual TREO 175 ...

Page 11: ...11 Explanatory drawing for installation of TREO 175 STICK ...

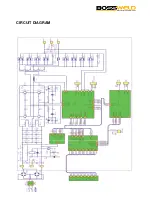

Page 22: ...22 CIRCUIT DIAGRAM ...

Page 30: ...30 Notes ...

Page 31: ...31 Notes ...