TRANSFLOW Transmission Cooling System Service Tool J-45096

9

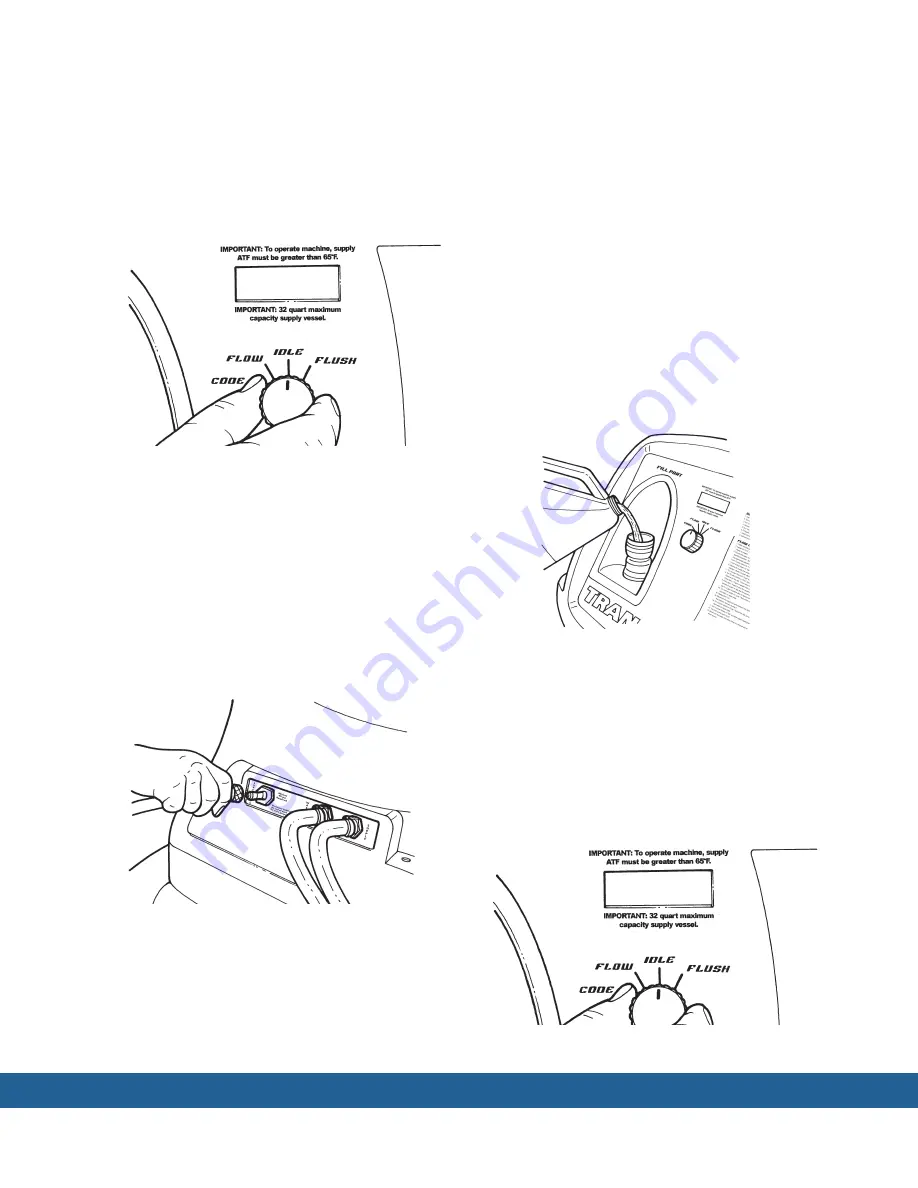

TransFlow Self-Test

Important: Whenever a cooler fails the flow

test, disconnect from the cooler lines and run

the self-test procedure to verify flow is 2.0 gpm

or greater. If less than 2.0 gpm, ensure the shop

air supply maintains a minimum of 90 PSI when

connected to the tester. The entire self-test should

take no more than one to two minutes to com-

plete. For additional information, refer to "Use-

ful Information/Helpful Hints" in this manual.

1. Remove the fill port cap.

2. Add two gallons of Dexron VI

®

ATF,

or equivalent, to the supply vessel through

the fill port. See Figure 1.

Caution: Do not overfill the supply vessel.

Damage to the unit may result. To verify the fluid

level, view the LCD screen display while filling

the unit to ensure that the fluid level does not

exceed 32 US quarts.

Note: If the Self-Test has already been carried

out, verify the fluid level by viewing the LCD

screen display. See Figure 2.

Figure 1

3. Connect an air hose from your compressed

air supply to the quick-disconnect on the rear

panel marked SUPPLY AIR. See Figure 3.

Note: Using an accurate pressure gauge, ensure

there is a minimum 90 psi of Supply Air at the

quick-disconnect.

Figure 2

IDLE

FLUID 00 QTS @ 075F

Figure 3

2. Verify that the main function switch is in the

IDLE position. Place the main power switch

(see Control Panel graphic on page 4

for its

location) in the ON position, and wait for the

IDLE screen to initialize. See Figure 2.

Figure 2

IDLE

FLUID 20 QTS @ 075F