Setting the Sensor Type:

This module can be programmed to output the air/fuel ratio in the following units.

Lambda (fuel independent)

AFR for gasoline

AFR for methanol

Custom units (use for fuels not listed)

To change the output units, left click on the drop down arrow button next the the box labeled ‘Sensor’ then make

your selections. If you select the ‘A/F Units, Custom’ sensor type for a fuel other than gasoline or methanol, you

will need to enter the fuels stochiometric air fuel ratio value in the ‘Raw data value B’ ‘will become’ box. You will

also need to enter the minimum and maximum result values. When you have fishished making all changes you must

send the updated configuration to the module by following the instructions in the

Sending the Configuration to the

module

section below.

Setting the Sample Rates

The factory default sample rate is set to the maximum of 50 samples per second. If you wish to lower the sample

rate to attain longer recording times, simply change the ‘V_Net Update Rate’ and ‘Logger Sample Rate’ to the

disired value. The ‘V_Net Update Rate’ should be set to value which is equal to or greater than the ‘Logger Sample

Rate’.

When you have fishished making all changes you must send the updated configuration to the module by

following the instructions in the

Sending the Configuration to the module

section below.

Setting the Channel Mode

If you are not going to use a sensor with one of the channels, for instance you have a four channel controller but are

using only three sensors, you should set the channel mode for the unused channel to

Disabled

. If you do not

disable the channel the LED indicator on the control box will flash an error indicating the sensor heater is not

present. When a channel is disabled the LED indicator on the control box will ignore all errors on that channel.

Also, the recorded data will display a error code value of –0.17 to indicate the channel is disabled.

Sending the Configuration to the module:

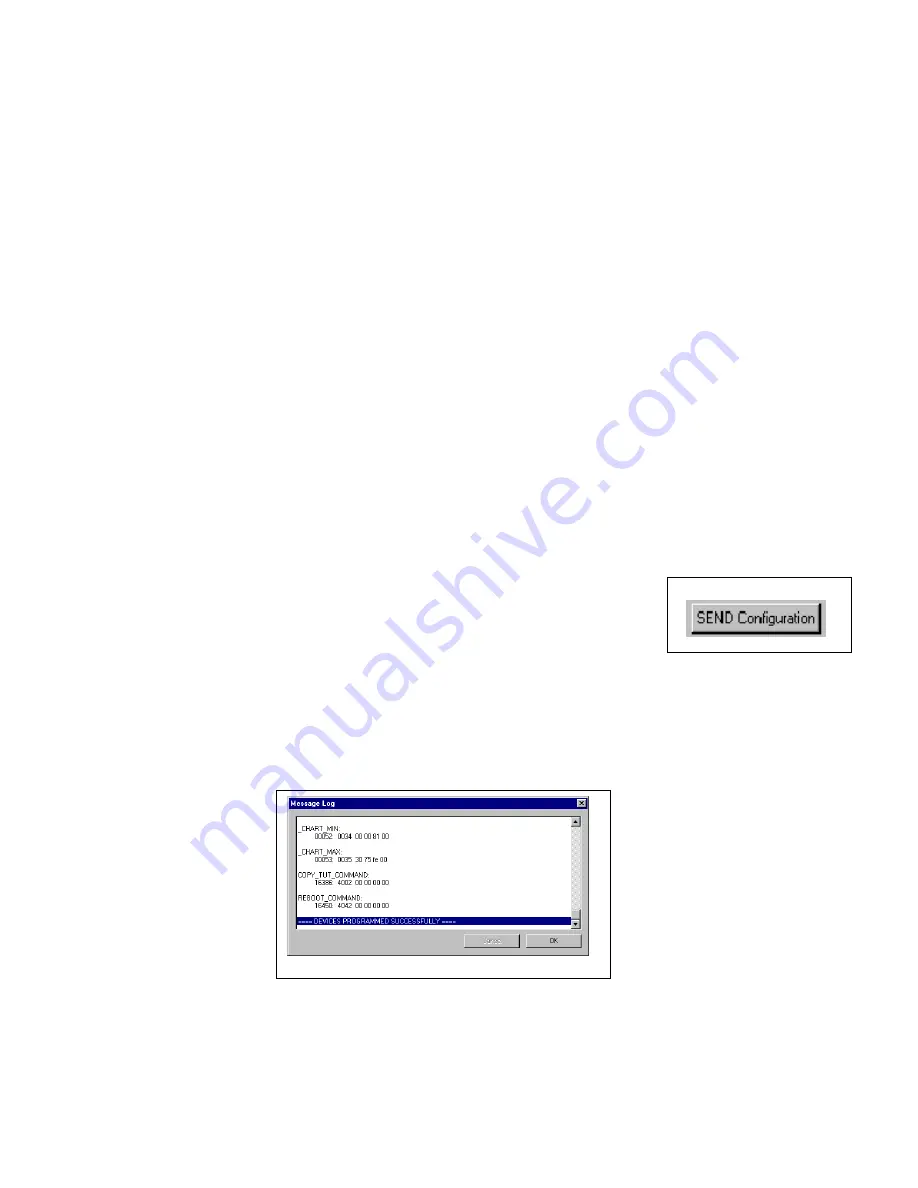

When you have finished editing the configuration on your PC, you will need to send

the information to the sensor module. Be sure the serial interface cable is connected

to your data logger and power is applied to the system. To send the information

position the mouse cursor over the

Send Configuration

button and click the left

mouse button. The progress box as shown below will be displayed.

When finished sending the message “

Device Programmed Successfully

” should be displayed at the bottom of the

progress box. If you receive an error message, turn power to the system off and then back on and repeat the send

configuration process. If problems persist contact RacePak.

Save the configuration file to disk and update the Module Configuration Setup Box on the front of this worksheet

with the new setup configuration.