Installation (only for approved contractors)

37

Tronic 4000 T – 6721843807 (2022/06)

▶ Use suitable connection accessories for the hydraulic

connection of the appliance.

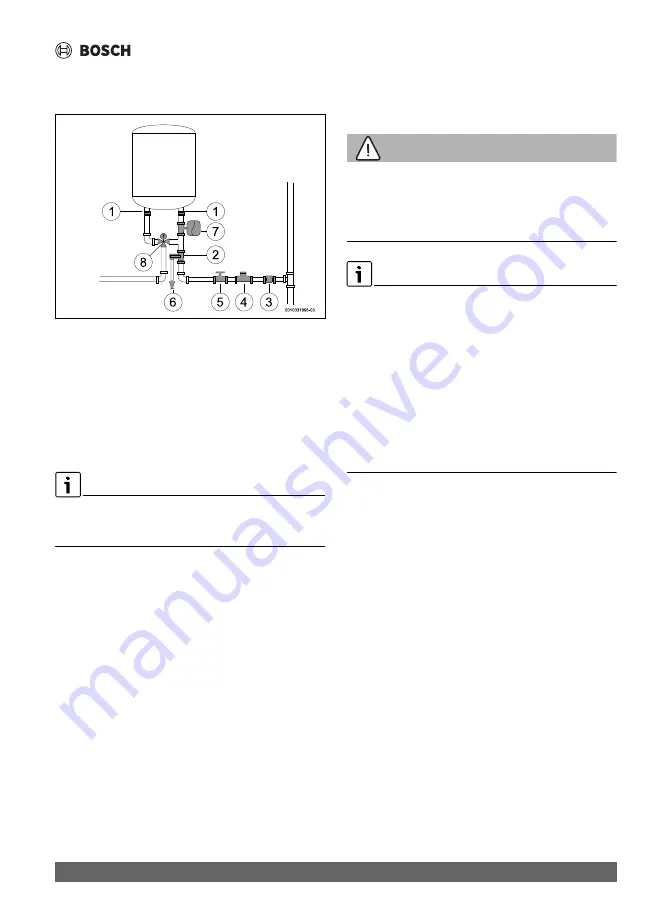

Fig. 11

[1] Galvanic insulation

[2] Pressure relief valve

[3] Non-return valve

[4] Reducer valve

[5] Cut-off Valve

[6] Drainage connection

[7] Expansion vessel

[8] Mixing valve

To avoid problems caused by sudden pressure changes in the

supply system, it is advisable to assemble a check valve

upstream of the appliance.

If there is a risk of freezing:

▶ Disconnect the appliance from the electricity.

▶ Vent the appliance (

chapter 4.6).

5.5

Pressure-relief valve

▶ Install the pressure relief valve on the water inlet of the

appliance.

WARNING

Risk of damage to property!

▶ Never obstruct the vent pipe of the pressure relief valve.

▶ Never install any accessory between the pressure relief

valve and the cold water inlet (right side) of the electric

DHW cylinder.

If the water inlet pressure is between 1.5 and 3 bar, it is not

necessary to install a pressure reducing valve.

If the water inlet pressure is above these values, it is necessary:

▶ to install a pressure reducing valve (Fig. 11, [4]). The

pressure relief valve will activate whenever the water

pressure in the appliance is above 8 bar (± 1 bar), for

which reason it is necessary to plan a way of draining off

this water.

▶ install an expansion vessel (Fig. 11, [7]) to stop the

pressure relief valve opening so frequently. The volume of

the expansion vessel should be equivalent to 5% of the

volume of the appliance.