34 / 64

IOM Manual VF-W_ATEX_gb - Translation of original instructions in Italian - Rev 03_0 - 30/09/16

VF 49

VF 49

VF 49 (*)

VF 49 (*)

B3

B6

B7

HS

P (IEC)

B8

V5

V6

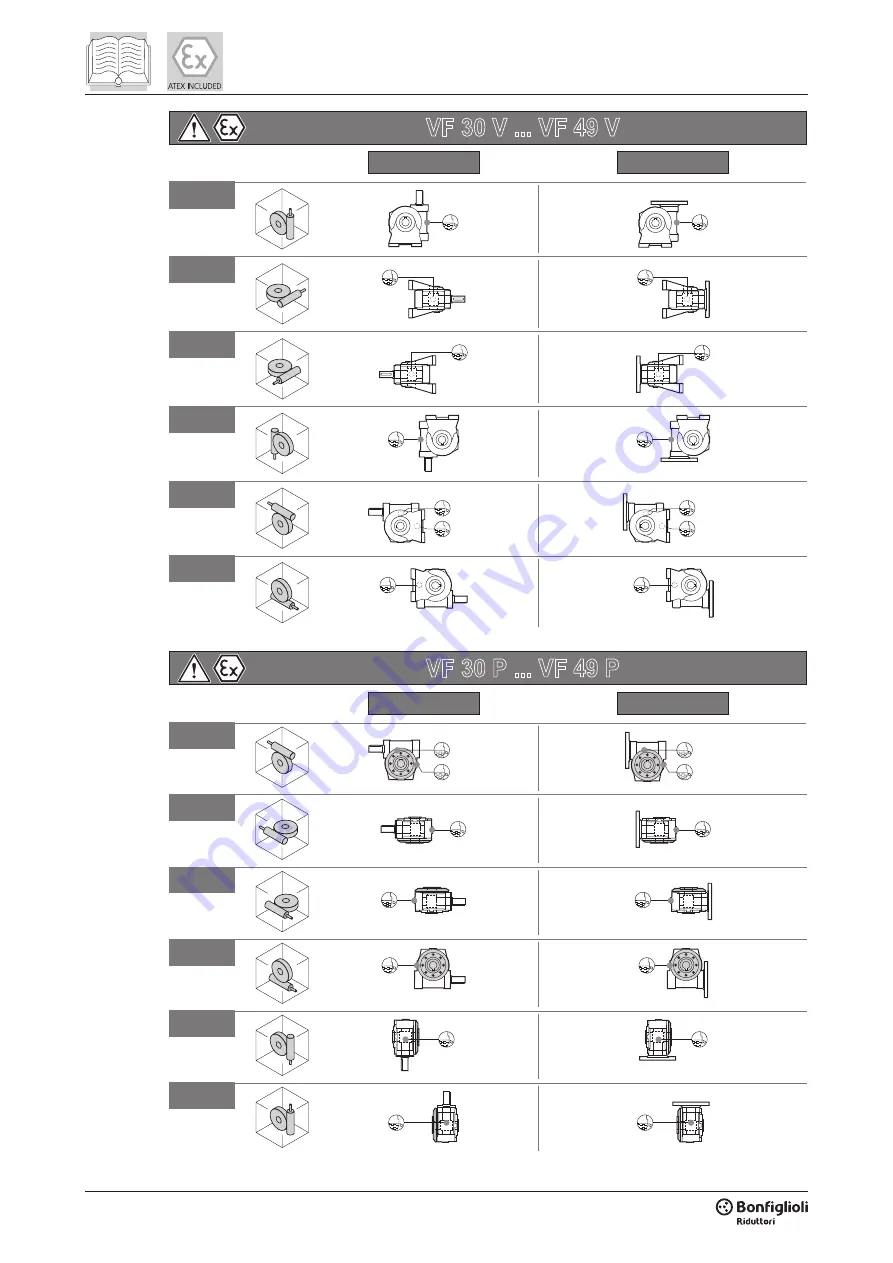

VF 30 V ... VF 49 V

B3

B6

B7

HS

P (IEC)

B8

V5

V6

VF 30 P ... VF 49 P

(*) On both sides