4-20 mA Input

mA

Displays current incoming signal

12.5

Å

É

ÄÈ

Displays motor run status

When in the run mode,

you can view the current

pump output speed and

input signal values by

pressing

RIGHT

the

arrow.

Tip!

Example 1

0

2

4

6

8

10

0

25

50

75

100

Pump

Motor Speed (%)

VDC Input

from external source

0 VDC = 0% Pump Output

10 VDC = 100% Pump Output

Example 2

0

25

50

75

100

0 VDC = 100% Pump Output

10 VDC = 0% Pump Output

Example 3

0

25

50

75

100

0 VDC = 20% Pump Output

8 VDC = 45.3% Pump Output

0%

Output

Pump

Motor Speed (%)

Pump

Motor Speed (%)

100%

Output

100%

Output

0%

Output

45.3%

Output

0

2

4

6

8

10

VDC Input

from external source

0

2

4

6

8

10

VDC Input

from external source

20%

Output

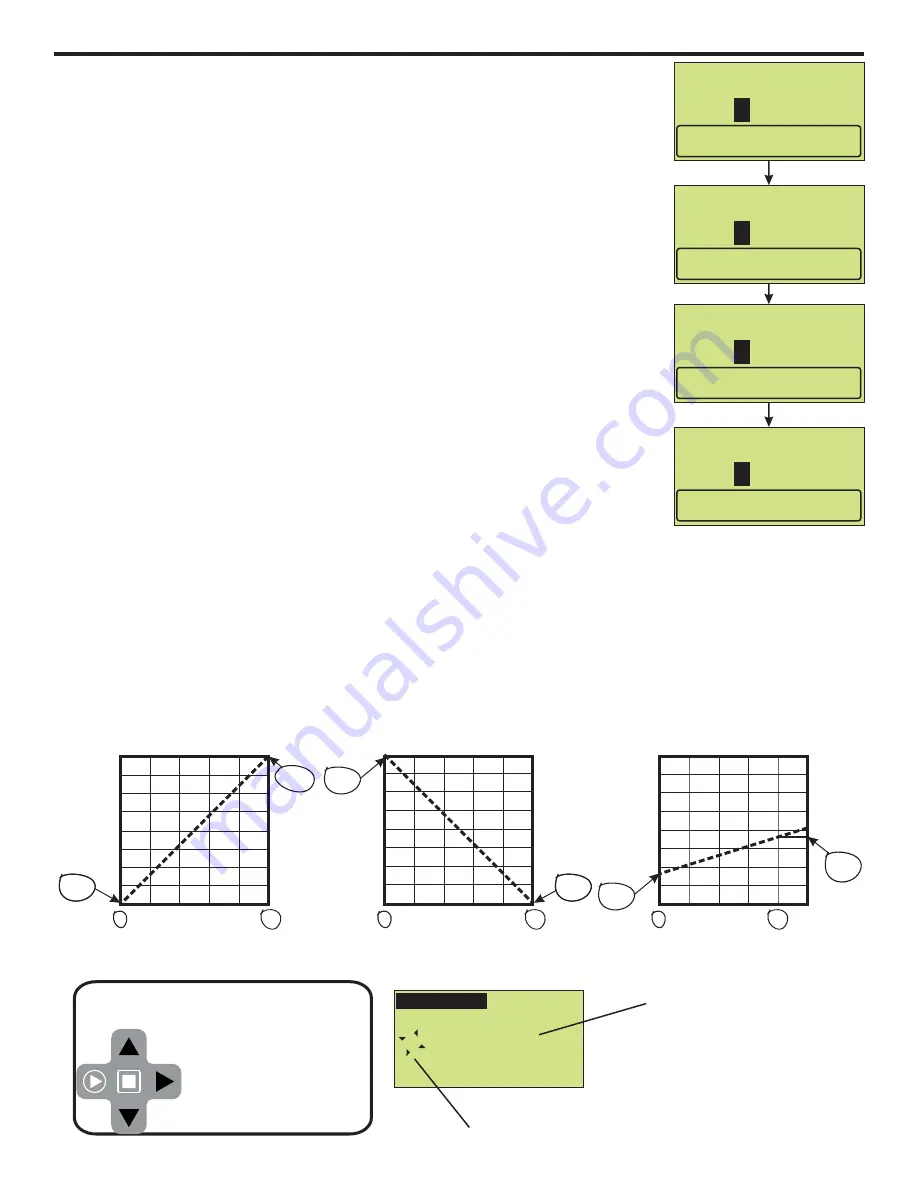

- 0-10 VDC Input

- 0-10 VDC Input

Min VDC Signal:

Input Min. VDC

0.00

0

- 0-10 VDC Input

- 0-10 VDC Input

Max VDC Signal:

Input Max. VDC signal

0.00

1

Press ENTER to set.

Press ENTER to set.

Flow @ Min Signal:

00.0

0

Flow @ Max Signal:

00.0

0

Input Flow Rate

RPM

Input Flow Rate

RPM

4.3.3

0 - 10 VDC Input (Volt DC)

Used to remotely control the pump with an incoming 0-10 VDC signal.

Default settings:

0 VDC = 0% motor speed

10 VDC = 100% motor speed

Press MODE button until

0 - 10 VDC Input i

s displayed in the top line of the

display.

To configure the pump, navigate to

0 - 10 VDC Input

menu by using the short-

cut method described at the beginning of the section, or by pressing MENU

button, then selecting Input Setup, Input Modes, and then

0 - 10 VDC Input

.

Four points on the slope must be defined; 1) a low VDC value, 2) an output rate

at the low VDC value, 3) a high VDC value, and 4) an output rate at the high

VDC value.

To input VDC values, press the RIGHT ARROW to select the digit to change,

press UP or DOWN arrow to scroll through 0 - 9 on selected digit. Press enter to

save changes and move to the next input screen.

To input flow rate values, press the RIGHT ARROW to select the user defined

flow rate unit of measure, motor RPM, or %Speed values. Press UP or DOWN

arrow to increase or decrease the value. Press and hold the arrow to increase or

decrease progressively faster. Press enter to save changes and move to the

next input screen.

Continue this process until all four screens have been configured.

If you used the short-cut to enter 0 - 10 VDC Input setup, press and hold Mode button until Run Mode screen is

displayed.

If you used the Menu button to navigate to 0 - 10 VDC Input setup, you must navigate back out of menu structure.

To do this you must select <-Esc at bottom of every screen menu until you see Run Mode screen displayed.

0

200 400 600 800 1000

0

25

50

75

100

Pump

Motor Speed (%)

Frequency Input (Hz)

0 Hz = 0% Pump Output

1000 Hz = 100% Pump Output

0

25

50

75

100

0 Hz = 100% Pump Output

1000 Hz = 0% Pump Output

0

25

50

75

100

0 Hz = 20% Pump Output

800 Hz = 50% Pump Output

0%

Output

Pump

Motor Speed (%)

Pump

Motor Speed (%)

100%

Output

100%

Output

0%

Output

50%

Output

0

200 400 600 800 1000

0

200 400 600 800 1000

20%

Output

Frequency Input (Hz)

Frequency Input (Hz)

Examples:

4.3.4

Frequency Input (Hz)

Used to remotely control the pump with an incoming high speed frequency

signal. Typically used with flow meters or other external devices.

Default settings:

0 Frequency (Hz) = 0% motor speed

1000 Frequency (Hz) = 100% motor speed

Press MODE button until

Frequency Input

is displayed in the top line of the

display.

To configure the pump, navigate to

Frequency Input

menu by using the short-

cut method described at the beginning of section, or by pressing MENU button,

then selecting Input Setup, Input Modes, and then

Frequency Input

.

Four points on the slope must be defined; 1) a low Hz value, 2) an output rate at

the low Hz value, 3) a high Hz value, and 4) an output rate at the high Hz value.

To input Hz values, press the RIGHT ARROW to select the digit to change,

press UP or DOWN arrow to scroll through 0 - 9 on selected digit. Press enter to

save changes and move to the next input screen.

To input flow rate values, press the RIGHT ARROW to select the user defined

flow rate unit of measure, motor RPM, or %Speed values. Press UP or DOWN

arrow to increase or decrease the value. Press and hold the arrow to increase or

decrease progressively faster. Press enter to save changes and move to the

next input screen.

Continue this process until all four screens have been configured.

If you used the short-cut to enter Frequency Input setup, press and hold Mode button until Run Mode screen is

displayed.

If you used the Menu button to navigate to Frequency Input setup, you must navigate back out of menu structure.

To do this you must select <-Esc at bottom of every screen menu until you see Run Mode screen displayed.

- Frequency Input

- Frequency Input

Min Freq. Signal:

Input Min. Freq. (Hz)

000

0

- Frequency Input

- Frequency Input

Max Freq. Signal:

Max. Freq. (Hz) signal

000

1

Press ENTER to set.

Press ENTER to set.

Flow @ Min Signal:

00.0

0

Flow @ Max Signal:

00.0

0

Input Flow Rate

GPH

Input Flow Rate

GPH

300

Frequency Input

Hz

Displays current incoming signal

Å

É

ÄÈ

When in the run mode,

you can view the current

pump output speed and

input signal values by

pressing

RIGHT

the

arrow.

Tip!

Displays motor run status

Page 18

Page 19

®

CHEM-FEED MD3

®

CHEM-FEED MD3

Summary of Contents for CHEM-FEED MD3 Series

Page 1: ...Diaphragm Metering Pump Series MD3 CHEM FEED...

Page 32: ...7 0 Exploded view and parts list 1 2 4 6 8 7 10 22 9 15 14 3 13 11 3 12 Page 32 CHEM FEED MD3...

Page 35: ...Page intentionally left blank Page 35 CHEM FEED MD3...

Page 36: ...Page intentionally left blank Page 36 CHEM FEED MD3...

Page 37: ...Page intentionally left blank Page 37 CHEM FEED MD3...