6

Service Procedures

25

Blue Seal Evolution Series GT45 / GT46 / GT60

©

Moffat Ltd, January 2007

Revision 1/

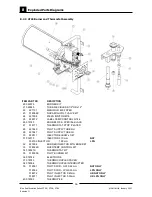

Figure 6.2.9a

5) Unscrew thermostat. Replace with new ther-

mostat ensuring sealant suitable for 250

°

C is

used on threads (Loctite 567 recommended).

Avoid rotating shaft on thermostat as internal

damage may occur.

Figure 6.2.9b

Thermostat

IMPORTANT:

DO NOT OVER-TIGHTEN THERMOSTAT OR

INTERNAL DAMAGE MAY OCCUR.

IT IS RECOMMENDED THAT A MAXIMUM

TORQUE OF 47.5 Nm (35ftlb) IS APPLIED TO

TIGHTEN.

6) Refit overtemp thermostat with the thread

connection being resealed. Re-assemble by

reversing the above procedure.

Ensure thermostat , overtemp, and H.T. leads

are not pinched when refitting control panel.

To calibrate thermostat refer 6.3.2.

Note:

On twin tank models both thermostat

knobs will need to be removed.

Thermostat leads

Figure 6.2.8b

6.2.9 Thermostat

1) Drain oil from fryer.

2) Remove control panel (refer 6.1.1).

3) Remove the overtemp thermostat (refer

6.3.4)

4) Disconnect thermostat leads from gas control

terminal block.

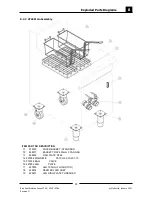

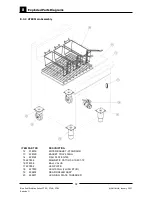

6) Once the rear is supported the front can be

pushed up into its location. The small notch in

each side of the venturi visible externally from

the burner body is for the front to back

location and should be located up into the top

corner panels when pushing up at the burner

at front. If correctly fitted the corner support

bracket securing holes. If not, check burner

fit.

7) Replace brackets and all connections to the

gas controls

8) Ensure underside burner box panel is refitted,

as failure to refit this panel will reduce

combustion and performance efficiency

Check the black

emissivity coating is

still intact.