Contact 1.800.762.1142 for assistance. Do not return to place of purchase.

PAGE NO

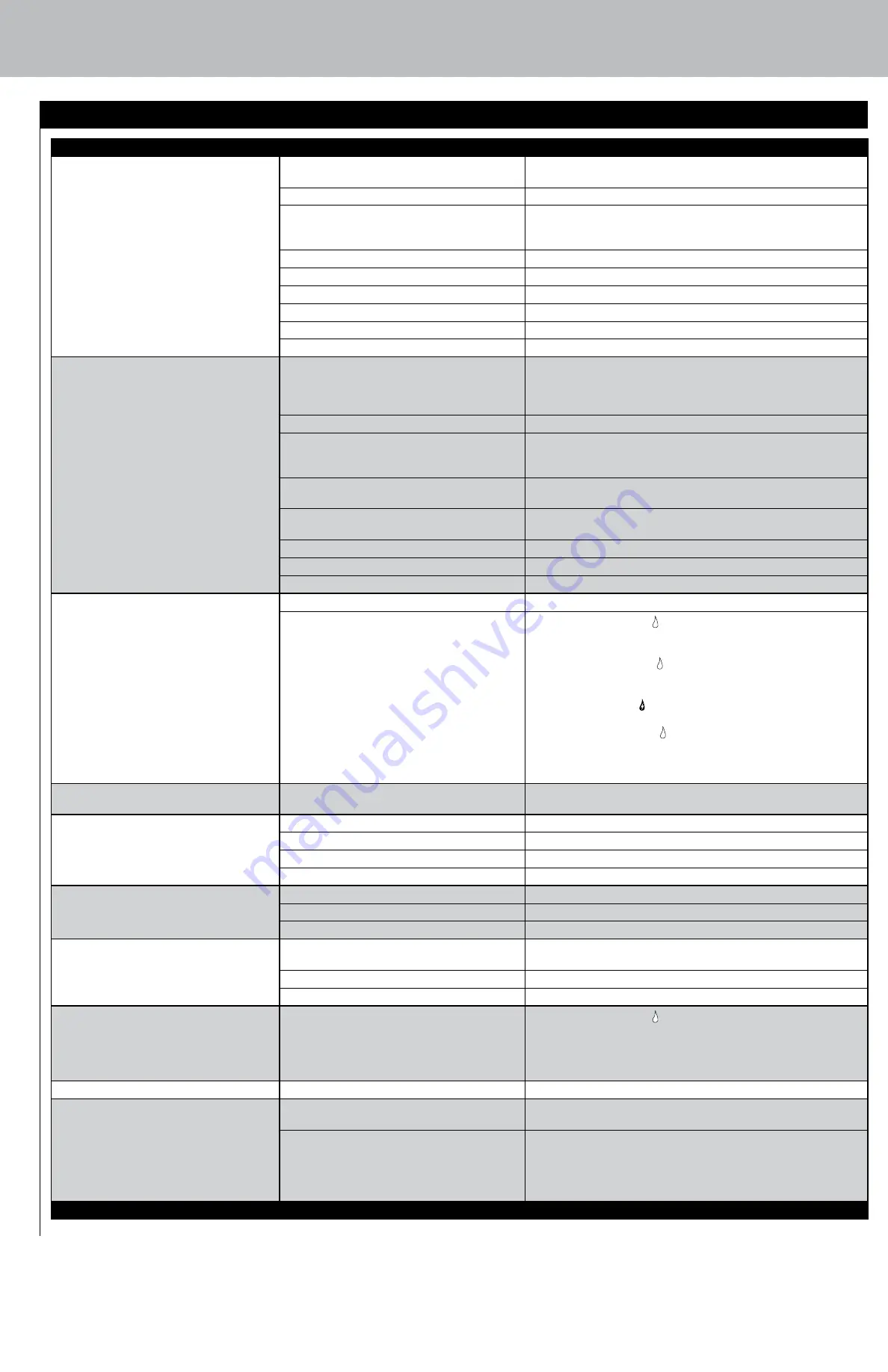

Troubleshooting

Problem

Possible Cause

Prevention/Cure

Burner will not light using ignitor

,0 GAS TANK VALVE IS CLOSED

Make sure regulator is securely attached to the LP gas tank, turn LP gas tank

VALVE TO h/0%.v

,0 GAS TANK IS LOW OR EMPTY

Replace or refill LP gas tank

LP gas

4URN ,0 GAS TANK TO h#,/3%$v

7AIT MINUTES FOR GAS TO CLEAR

&OLLOW h#HECKING FOR ,EAKSv IN THE OWNERS MANUAL

7IRES OR ELECTRODE COVERED WITH COOKING RESIDUE

#LEAN WIRE ANDOR ELECTRODE WITH RUBBING ALCOHOL

%LECTRODE AND BURNERS ARE WET

7IPE DRY WITH CLOTH

%LECTRODE CRACKED OR BROKEN SPARKS AT CRACK

Replace electrode

Wire loose or disconnected

2ECONNECT WIRE OR REPLACE ELECTRODEWIRE ASSEMBLY

7IRE IS SHORTING SPARKING BETWEEN IGNITOR AND ELECTRODE 2EPLACE IGNITOR WIREELECTRODE ASSEMBLY

Bad ignitor

Replace ignitor

Burner will not light with match

.O GAS FLOW

Check if LP gas tank is empty

! )F EMPTY REPLACE OR RElLL

" )F ,0 GAS TANK IS NOT EMPTY REFER TO h3UDDEN DROP IN GAS mOW OR REDUCED

mAME HEIGHTv

,0 GAS TANK IS LOW OR EMPTY

Replace or refill LP gas tank

LP gas

4URN ,0 GAS TANK TO h#,/3%$v

7AIT MINUTES FOR GAS TO CLEAR

&OLLOW h#HECKING FOR ,EAKSv IN THE OWNERS MANUAL

Coupling nut and regulator not fully connected

Turning the coupling nut about one-half to three quarters additional turn until

SOLID STOP

Tighten by hand only-do not use tools.

/BSTRUCTION OF GAS FLOW

#LEAR BURNER TUBES

#HECK FOR BENT OR KINKED HOSE

$ISENGAGEMENT OF BURNER TO VALVE

2EENGAGE BURNER AND VALVE

3PIDER WEBS OR INSECT NEST IN VENTURI

#LEAN VENTURI AND BURNER TUBE

Burner ports clogged or blocked

Clean burner ports

Sudden drop in gas flow or reduced flame height

/UT OF GAS

Replace or refill LP gas tank

%XCESS FLOW SAFETY DEVICE MAY HAVE BEEN ACTIVATED

4URN CONTROL KNOBS TO h/&& v

7AIT SECONDS AND LIGHT GRILL

)F mAMES ARE STILL TOO LOW RESET THE EXCESSIVE mOW SAFETY DEVICE

A 4URN CONTROL KNOBS h/&& v

B 4URN ,0 GAS TANK VALVE TO h#,/3%$v

C $ISCONNECT REGULATOR

D 4URN CONTROL KNOBS TO ()'(

E 7AIT MINUTE

F 4URN CONTROL KNOBS TO h/&& v

G 2ECONNECT REGULATOR AND LEAK CHECK CONNECTIONS

H 3LOWLY TURN ,0 GAS TANK VALVE TO h/0%.v

I 7AIT SECONDS AND THEN LIGHT GRILL PER h,IGHTING )NSTRUCTIONSv

Irregular flame pattern, flame does not run the

full length of burner

Burner ports are clogged or blocked

Clean burner ports

Flame is yellow or orange

.EW BURNER MAY HAVE RESIDUAL MANUFACTURING OILS

"URN GRILL FOR MINUTES WITH THE LID CLOSED

3PIDER WEBS OR INSECT NEST IN VENTURI

#LEAN VENTURI

&OOD RESIDUE GREASE ETC

Clean burner

0OOR ALIGNMENT OF VALVE TO BURNER VENTURI

!SSURE BURNER VENTURI IS PROPERLY ENGAGED WITH VALVE

Flame blow out

(IGH OR GUSTING WINDS

$O NOT USE GRILL IN HIGH WINDS

,OW ON ,0 'AS

Replace or refill LP gas tank

%XCESS FLOW VALVE TRIPPED

2EFER TO h3UDDEN DROP IN GAS FLOW OR REDUCED FLAME HEIGHTv

Flare-up

Grease buildup

2EMOVE AND CLEAN ALL GRILL PARTS PER h#LEANING AND #AREv INSTRUCTIONS IN THE

OWNERS MANUAL

%XCESS FAT IN MEAT

Trim fat from meat before grilling

%XCESSIVE COOKING TEMPERATURE

!DJUST LOWER COOKING TEMPERATURE

Persistent grease fire

Grease trapped by food buildup around burner system

4URN CONTROL KNOBS TO h/&& v

4URN ,0 GAS TANK VALVE TO h#,/3%$v

,EAVE LID IN CLOSED POSITION AND LET lRE BURN OUT

!FTER GRILL COOLS REMOVE AND CLEAN ALL PARTS PER h#LEANING AND #AREv

INSTRUCTIONS IN THE OWNERS MANUAL

Flashback (fire in burner tube(s))

Burner and/or burner tubes are blocked

Clean burner and/or burner tubes

Inside of lid is peeling (like paint peeling)

The lid is stainless steel, not painted

Baked on grease buildup has turned to carbon and is flaking off, clean

THOROUGHLY PER h#LEANING AND #AREv INSTRUCTIONS IN THE OWNERS MANUAL

The lid is coated/painted

s 4HIS CAN BE FROM BAKED ON GREASE BUILDUP THAT HAS TURNED INTO CARBON AND IS

flaking off

s #LEAN THOROUGHLY PER h#LEANING AND #AREv INSTRUCTIONS IN THE OWNERS MANUAL

s !FTER CLEANING IF YOU CAN SEE STEEL PLEASE CALL OUT #USTOMER #ARE AT

For more assistance please visit us online at www.bluerhino.com or call 1.800.762.1142.