4. Sharpen the blade.

●

If the blade is struck a break by metal or stone or some hard subjects, please

sharpen the break lot at first.

●

Avoid changing the blade color and anneal when sharpening the blade.

●

It may result in a breach on the edge if you overexert.

●

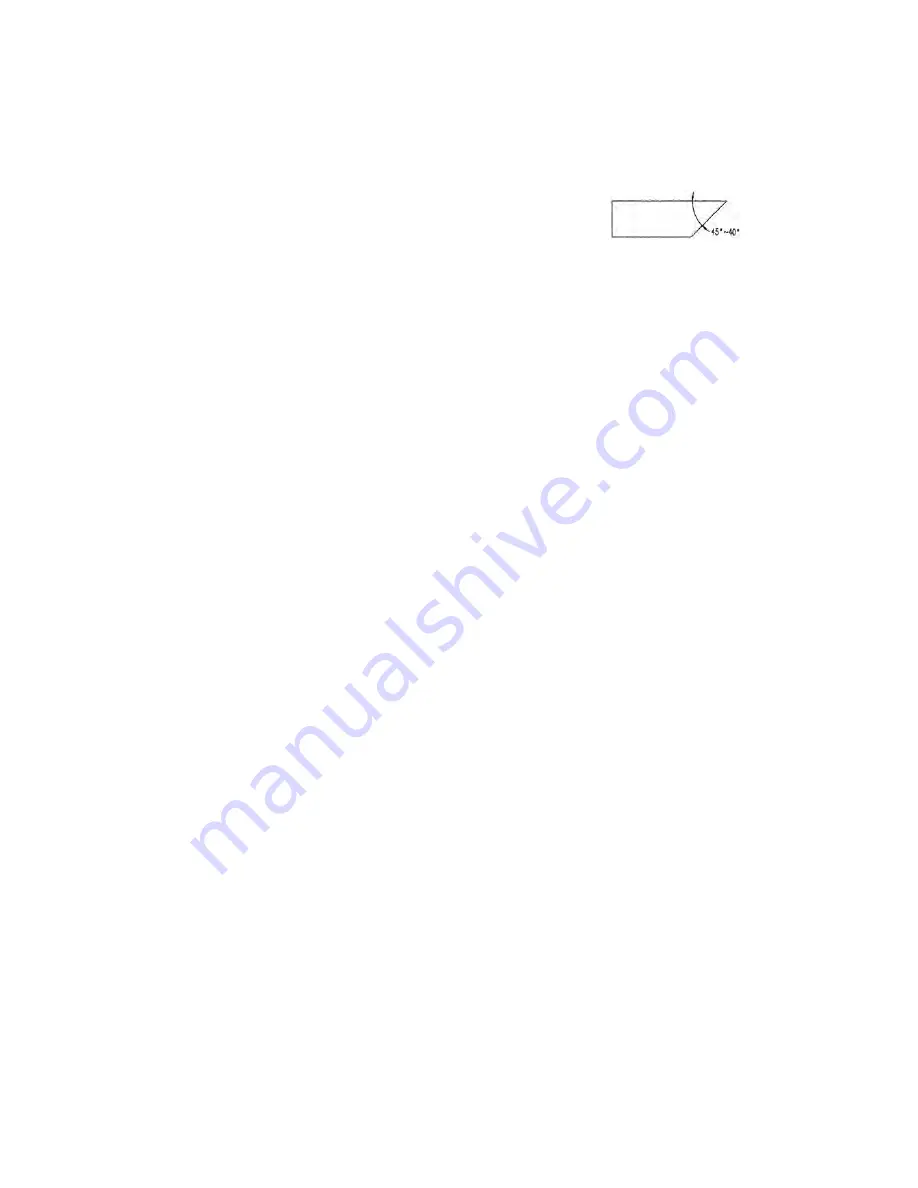

Knifepoint angle should be kept in 45-40 degree.

●

Two pieces of blade should keep the same weight as

each other. They will shake if there is much difference

between weight.

5. Put the blade back to the place where they are removed and tighten with nuts.

6. Replace the board covering the blade.

7. Replace the discharge screen.

8. Close the outlet of the discharge.

IX. Adjusting the belt.

There is a “V” belt under belt cover transmitting energy from engine to the blade tray. The

belt will be getting loose and skid after used for some time. So tension adjustment is required.

1. Turn off the engine and remove the belt cover.

2. Loose the four location nuts on the engine.

3. Move engine forward till the “V” belt is tight.

4. Put the main pulley and affiliated pulley in the same plane. (A ruler can be used to measure

if lack of experience). Tighten the four location holes on the engine.

5. Set the belt cover back to its place.

X. Replace the belt

The “V” belt need for replacement if it is too long or damaged.

1. Turn off the engine and remove the belt cover.

2. Remove the old belt. Pull the belt outside by tools and turn the pulley gradually to remove

the pulley.

Note: please mind your finger.

3. Place the new belt in the main pulley first (“V” belt on engine) and then to the affiliated

pulley beside the blade tray.

4. The new belt is tighter than the old. To assembly the new one is not as easily as to remove

the old. When you hold the belt into the slot, do not put your finger between the pulley and

belt, which may result in injury.

5. Replace the belt cover.

Summary of Contents for CS-65

Page 1: ...CS 65 6 5HP CHIPPER SHREDDER OPERATION MANUAL...

Page 10: ......