BWOS 30100 SERVICE MANUAL

36

boards

bus.

the board to

board cables.

WHEN A FAILURE OCCURS, THE DISPLAY SHOWS THE WRITING FXX Err, WHEREAS xx IS ONE OF THE ERROR CODES LISTED IN

THE TABLE.

TO RESET THE FAILURE, FIRST THE CAUSE MUST BE REMOVED. THE COOKING MODE AND THE TEMPERATURE SELECTORS

MUST BE TURNED INTO “OFF” AND “PRESET” POSITIONS RESPECTIVELY.

4.2 OVEN NOT OPERATIVE

Anomaly

Possible

Cause

Corrective Action

section

Oven does not run

No power supply

Main breaker or

main fuses

Replace the fuses

Short circuit

Find the short circuit and

remove it

Oven does not run

Power supply ok.

Connections to

Display or the

Power board

Replace power board

7.17

4.3 COOLING FAN PROBLEMS

Anomaly

Possible

Cause

Corrective Action

section

Fan does not run

No power supply

78Ω resistor

broken

Replace 78Ω resistor

7.12

Power board

relay not

switching

Replace Power board

7.17

Fan does not run

Power supply ok.

Blocked rotor

Replace fan

7.2

7.3

Burned coil

Replace fan

7.2

7.3

Noisy fan

Lose

attachment

screws on

cooling

assembly

Check attachment screws on

cooling assembly or replace

fan

7.2

7.3

The cooling fan is

always on

The control is

measuring a

high

temperature

inside the cavity

Turn the cooking mode

selector in a cooking mode

position,F01 (F02) should

occur.

--

Summary of Contents for 8978983800

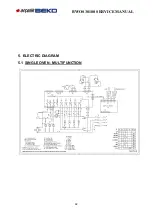

Page 42: ...BWOS 30100 SERVICE MANUAL 42 5 ELECTRIC DIAGRAM 5 1 SINGLE OVEN MULTIFUNCTION...

Page 43: ...BWOS 30100 SERVICE MANUAL 43 6 EXPLODED PARTS 6 1 SINGLE OVEN 30...

Page 44: ...BWOS 30100 SERVICE MANUAL 44...

Page 45: ...BWOS 30100 SERVICE MANUAL 45...

Page 46: ...BWOS 30100 SERVICE MANUAL 46...

Page 47: ...BWOS 30100 SERVICE MANUAL 47...

Page 48: ...BWOS 30100 SERVICE MANUAL 48...

Page 70: ...BWOS 30100 SERVICE MANUAL 70...