ANY TAMPERING WITH THE INTERNAL CONNECTIONS IS PROHIBITED

AND WILL VOID THE WARRANTY.

DISCONNECT THE POWER SUPPLY PRIOR TO ANY OPERATIONS WITH THE UNIT.

CONNECTION OF THE UNIT TO POWER MAINS IS ALLOWED BY A QUALIFIED

ELECTRICIAN WITH A WORK PERMIT FOR THE ELECTRIC UNITS UP TO 1000 V AFTER

CAREFUL READING OF THE PRESENT USER’S MANUAL. THE RATED ELECTRICAL

PARAMETERS OF THE UNIT ARE GIVEN ON THE MANUFACTURER’S LABEL.

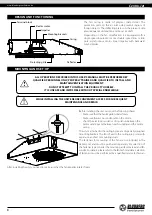

CONNECTION TO POWER MAINS

The impulse centrifugal fan is a component part of the ventilation system and is not designed for standalone operation. The fan must be

integrated in the ventilation or smoke extraction system and equipped with automatic control.

The fan is rated for connection to three-phase ac 400 V/ 50 Hz power mains.

The cable selection must be based on the maximum permissible wire heating depending on the wire type, its insulation, length and

installation method (i.e. overhead, in pipes or inside the walls).

Connection of the fan for smoke extraction must be performed via a cable with a respective fire-resistance class. Quality and mounting

of the fire-resistant power cable must provide trouble-free durable operation of the fan in case of fire. The fan motor has no integrated

thermal protection. Consider this fact during selection of the motor starter and the contactor.

The fan motor must be connected to power supply in compliance

with wiring diagram and terminal designations and wired through the

terminal block X1. The terminal block is located in the terminal box and

the terminal marking is shown on the label attached to the terminal

box. The terminal box is located inside of the fan casing.

Wiring steps:

• Unscrew the terminal box from the casing wall and remove it.

• Unscrew the terminal box lid and remove it.

• Route the power cable through the sealed cable gland on the

terminal box lid and wire the unit in compliance with the wiring

diagram.

• Re-install and re-attach the terminal box.

www.blaubergventilatoren.de

centro-Jet

9