Let us review three variations of a heavy start:

1. The feed line performance is barely sufficient or insufficient to maintain the induced current.

Typical symptoms:

Upon starting the circuit breakers at the system input are tripped; the lights, certain relays and contactors go off,

and the supply generator shuts down.

Solution:

In the best-case scenario an SS device may help reduce the in-rush current to 250 % of the motor rated current. If this is

insufficient, an FC is necessary.

2. The motor cannot start the mechanism with DOL starting.

Typical symptoms:

The motor fails to turn or “freezes” at certain speed which is maintained until actuation of the protection suite.

Solution:

This problem may not be solved with an SS device. The motor develops insufficient shaft torque. However, this problem can

be addressed by using an FC, but each case may be different.

3. The motor spins up the mechanism with authority, but fails to reach the rated rotation speed.

Typical symptoms:

The input automatic circuit breaker is tripped during spin-up. This often happens with heavy-weight fans with a

considerable rotation speed.

Solution:

Such problems may be addressed with an SS device, but not with 100 % certainty. The closer the motor speed to the rated

value during the actuation of the protective equipment, the higher the chances of success. The use of an FC in this case helps solve the

problem fundamentally.

Standard switching equipment (automatic circuit breakers, contactors and motor starters) is not designed to withstand

prolonged overloads normally causing the fan to shut down automatically DOL starting that continues for a long period of

time.

Using switching equipment with a higher maximum current rating renders the electric motor protection system less sensitive.

As a result the switching equipment will not be able to detect motor overload in time due to a high current sensing threshold.

Such problems as mentioned above can only be addressed by utilizing a soft starter or a frequency converter to start the fan.

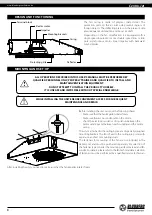

COMMISSIONING

THE ORGANISATION RESPONSIBLE FOR THE COMMISSIONING SHALL BE RESPONSIBLE

FOR PROPER MOTOR PHASING AND STARTING PATTERN SELECTION.

• After fan starting make sure that the motor rotates properly without undue vibration and abnormal noise.

• Make sure that the fan impeller rotates in the direction marked by the arrow on the fan casing. If necessary, change the impeller

rotation direction by changing the phase sequence on the electric motor terminals.

• Make sure that the fan energy consumption complies with the value given on the equipment nameplate and check the motor for

overheating.

• The phase current should be checked once the fan reaches the rated operating conditions.

• Do not switch the fan on and off several times without pauses as this may result in damage to the winding or insulation due to

overheating.

DURING STARTING THE IN-RUSH CURRENTS OF THE FAN MAY SEVERAL TIMES EXCEED

THE RATED VALUES.

SEE “ASYNCHRONOUS ELECTRIC MOTOR STARTING METHODS” IN THE “CONNECTION

TO POWER MAINS” SECTION

centro-Jet

12

www.blaubergventilatoren.de