6

5. To remove locknuts and lockwashers (24A and 24B):

a. Bend up the engaged lockwasher tang and rotate the

locknut counterclockwise to remove it from the shaft

b. Slide the lockwasher (24B) off the shaft. Inspect the

lockwasher for damage and replace as required.

c. Repeat steps a and b on the opposite shaft end.

6. Remove the head capscrews (21). Each head (20) has a

threaded jackscrew hole to facilitate removal. Insert a

capscrew (21) into the jackscrew hole to easily remove

head from the casing (12).

NOTE: It is a good practice

to attach pump heads to the same ends they were

removed from.

7. Slide the head (20) off the shaft. The bearing (24),

mechanical seal stationary seat and stationary O-ring

(153A & 153D) will come off with the head assembly.

a. Pull the bearing (24) from the housing in the head.

b. To remove the mechanical seal stationary seat (153A),

use the blunt end of a screw driver to gently push the

backside of the stationary seat from the head. Place a

cloth under the seal to avoid damage. Be careful not to

contact the polished face of the seal during removal.

Remove and discard mechanical seal stationary O-ring.

8. Carefully pull the rotating seal assembly, consisting of seal

jacket (153C), rotating seal face and rotating O-ring (153B

& 153E) from the shaft. Remove and discard the rotating

O-ring (153E).

9. Carefully remove the disc (71) and head O-ring (72).

10. Pull the rotor and shaft (13) from the casing (12). While

one hand is pulling the shaft, the other hand should be

cupped underneath the rotor to prevent the vanes (14)

from falling out. Carefully set the rotor and shaft (13) aside

for future vane replacement and reassembly.

11. Lay the pump flat with the remaining head facing upward to

remove the head assembly, mechanical seal, and disc from

the outboard side of the pump, as instructed in steps 6 - 9

above.

12. If necessary, remove the liner (41) by tapping around the

outside diameter of the liner with a hard wood drift and a

hammer until it is driven from the casing (12).

PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft. Remove any

burrs from the liner.

Reassemble the OUTBOARD side of the pump first:

1. Align the liner keyway with the setscrew (74) that extends

down into the pump casing (12) and start the liner (41) into

the casing. The word “INTAKE” cast on the liner must face

the intake port of the pump casing. Uniformly tap the outer

edge of the liner with a rubber mallet to fully insert into the

casing.

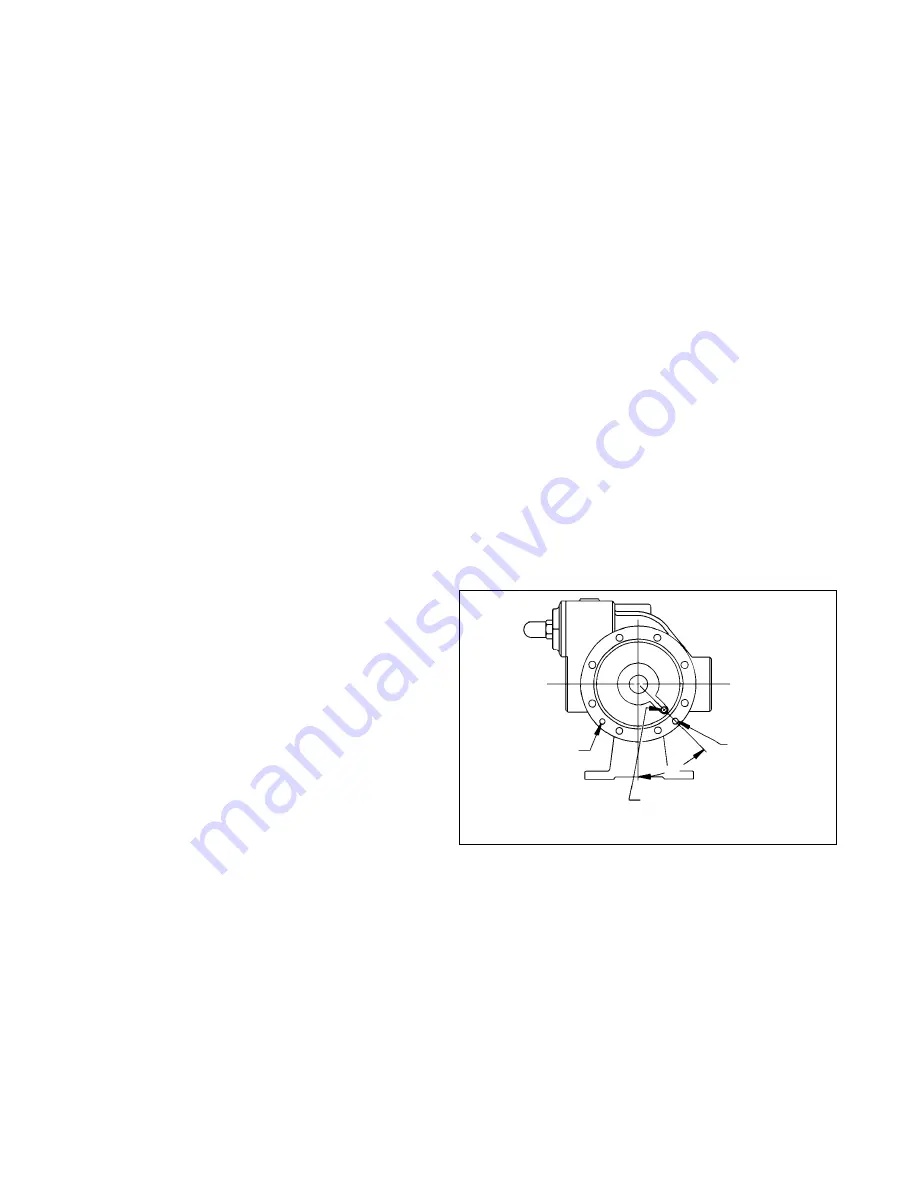

2. Place the disc (71) against the liner (41) with the seal

cavity outward and disc relief hole located as shown in

Figure 5.

MAINTENANCE

3. Without installing the head O-ring (72) or mechanical seal

components, temporarily attach the outboard head (20)

and bearing (24) to the casing (12). Install and hand-

tighten two head capscrews (21), 180 degrees apart. This

head will be used to hold and align the rotor and shaft (13)

while the inboard side of the pump is assembled.

NOTE: It is a good practice to attach pump heads to

the same ends they were removed from.

4. Before installing the rotor & shaft assembly (13), the

direction of pump rotation must be determined as follows:

If the pump is to be

right-hand

with

clockwise

rotation,

the intake port and the relief valve must be on the

right

with the drive end of the shaft pointing towards the

observer.

If the pump is to be

left-hand

with

counterclockwise

rotation, the intake port and the relief valve must be on

the

left

with the drive end of the shaft pointing towards

the observer.

5. Remove the vanes (14) and push rods (77) (if equipped)

from the rotor and shaft assembly (13). Inspect for wear

and damage, and replace as follows:

a. Insert the vanes (14) into the bottom rotor slots with the

relief grooves facing in the direction of pump rotation,

and with the rounded edges outward. See Figure 4.

Figure 5 - Disc Relief Hole Location

DISCHARGE

INTAKE

45

o

Position disc relief hole here.

Locator pin

Locator pin

b. If the pump is equipped with an optional four-vane rotor

and shaft (13A), hold the two bottom vanes (14) in

place while inserting the two push rods (77).

c. After the bottom vanes (14) (and push rods, (77) if

equipped) are installed, carefully insert the non-driven

end of rotor and shaft into the casing (12).

d. Install all remaining vanes (14) into the top positions of

the rotor.

6. Install the disc (71) on the inboard side of the pump with

the seal cavity facing outward and the disc relief hole

located as shown in Figure 5.

7. Install a new head O-ring (72) in the groove between the

disc (71) and the casing(12).