4)

Tunneling

Tunneling is another area where there is a good application for the Power Rock splitter.

This is especially practical for instances where blasting is not an option, due to security issues

or because the smoke or noise would interfere with normal and continuous use of existing,

connected operations. Where new tunnels have to go under existing operations or where

they must break into existing tunnels there is no safer method than the Power Rock Splitter.

The broken material can be easily contained and fragmentation is not a problem. The

Power Rock Splitter offers very precise control of what is to be broken and to what

specifications. The most difficult part of this type of work is to create a free face or void,

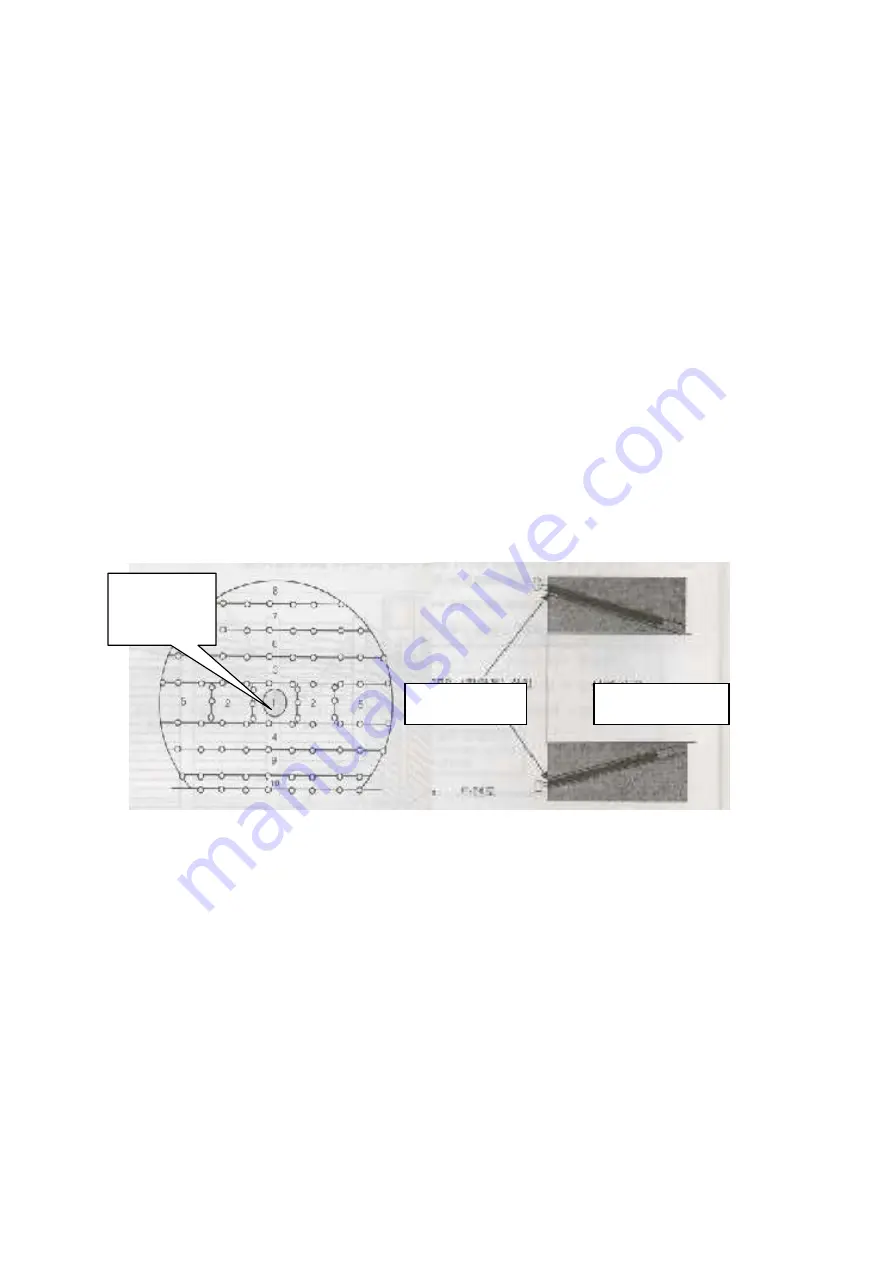

allowing the drill and breaking pattern to be expanded. Here are two methods and patterns

to create that free face.

The first method is to drill a large diameter hole with a crawler mounted Down-the- Hole

(DTH) drill creating an opening for additional holes to break into. The second method is

to drill a series of holes, which when broken in sequence creates an ever expanding void, into

which the remaining holes are broken.

Large Center Hole Method

<Fig 4-6>

Drilled center hole

Power cylinder

Large

center hole