Rev. 1.01

- 15 -

SRP-275III

3. Setting the Switches

3-1 Setting the DIP Switch

Although the factory settings are best for almost all users, if you have special requirements,

you can change the DIP Switch. Your printer has two sets of DIP Switches. The functions

of the switches are shown in the following table.

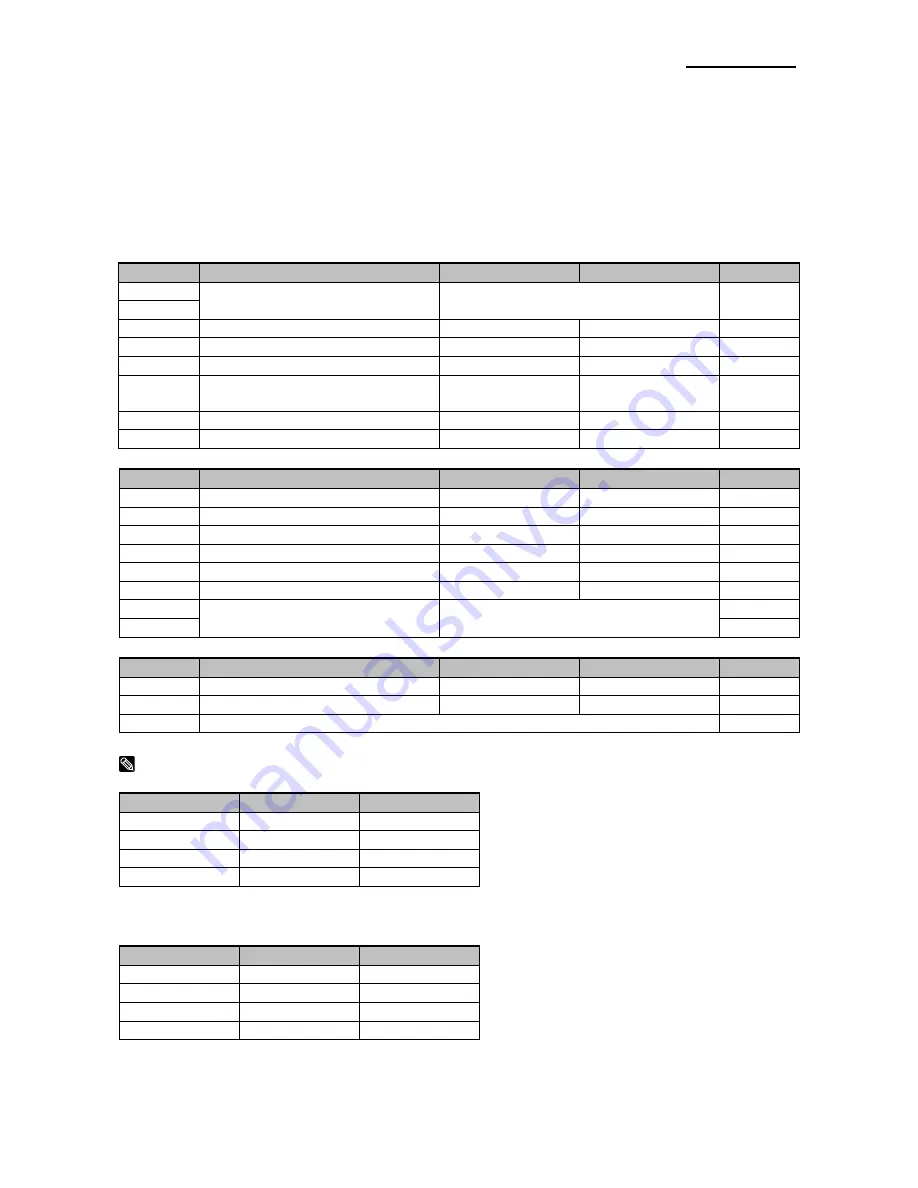

• DIP Switch 1

Switch

Function

ON

OFF

Default

1-1

Emulation Selection (*1)

Refer to the following table

OFF

1-2

1-3

Auto cutter

Enable

Disable

ON

1-4

Compatible with SRP-275

Enable

Disable

OFF

1-5

Serial interface selection

Memory Switch

DIP Switch

OFF

1-6

Print NV bit image #1 after

cutting

Enable

Disable

OFF

1-7

Near end switch

Enable

Disable

ON

1-8

Printing column

42

40

OFF

• DIP Switch 2 (RS232C serial interface model)

Switch

Function

ON

OFF

Default

2-1

Data receive error

Ignore

Print “?”

OFF

2-2

Black Mark Sensor

Enable

Disable

OFF

2-3

Hand shaking

XON/XOFF

DTR/DSR

OFF

2-4

Word length

7 bits

8 bits

OFF

2-5

Parity check

Enable

Disable

OFF

2-6

Parity selection

EVEN

ODD

OFF

2-7

Baud rate selection (*2)

Refer to the following table

OFF

2-8

OFF

• DIP Switch 2 (Parallel interface model)

Switch

Function

ON

OFF

Default

2-1

Auto Line Feed

Enable

Disable

OFF

2-2

Black Mark Sensor

Enable

Disable

OFF

2-3~8

Undefined

OFF

NOTES

(*1) Emulation Selection (DSW 1-1 and 1-2)

Emulation

1-1

1-2

BXL/POS

OFF

OFF

BXL/POS-KP

ON

ON

STAR

OFF

ON

CITIZEN

ON

OFF

- BXL/POS-KP(Kitchen Printer mode) : A alarm is generated by printer after auto cutting

and in paper end error.

(*2) Baud rate selection (Transmission speed)

Transmission

2-7

2-8

2400 baud

ON

ON

4800 baud

OFF

ON

9600 baud

OFF

OFF

19200 baud

ON

OFF