EX200 Electro-Hydraulic Actuator Positioner

Bifold Orange Limited.

Drwg. No.: ORM0001 Issue : 1 Date : 24/06/2015 Page :

4 of 20

EX200 Part Number Selection Chart

Other options available on request to Bifold Orange.

Operation

The instrument compares two analogue signals, one representing the desired position (command signal) and the other

representing the actual position (feedback signal) of the actuator.

A difference between these two signals will cause one of the EX200 outputs to operate, driving the actuator to the desired

position. A positional Dead-

zone may be adjusted to overcome “hunting” problems associated with mechanical overrun of

the actuator.

The speed of transit of the actuator can be reduced by selecting the stepping mode that provides independently

adjustable on and off times for the open and close solenoid operation.

An OK light is present on the front display that is linked to the Auxiliary Solenoid Output, this is lit when the EX200 is

operating correctly.

Physical

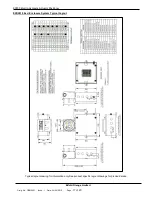

The

EX200 with part number “D” for housing selection is contained in a small DIN rail mounted polyester enclosure

measuring 85 x 70 x 58h. The circuit boards are coated with a resist layer that protects the track from moderate

condensation and mould growth problems. Connections are via screw terminals with a capacity of 2.5mm

2

but the use of

ferrules or crimps is recommended. All adjustments are accessible on the front panel of the enclosure. Initial

configuration adjustments are via internal jumper links, usually set to customer requirements on order.

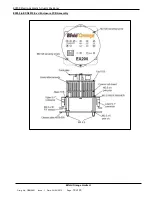

The EX200

with part number “C” for housing selection is mounted on a chassis plate and housed within an Ex d

enclosure. The circuit boards are coated with a resist layer that protects the track from moderate condensation and

mould growth problems. Connections within the Ex d enclosure

are by factory assembled 0.1” connectors and must not

be disturbed or re-wired.

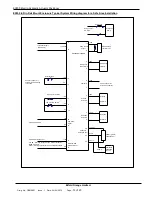

Wiring

Wiring should be completed by suitably trained personnel taking into account the following notes:

To ensure RFI compliance the analogue signals should be routed in copper braided screened cables with a fill factor

density of at least 0.7.

The screens should be terminated to the metal of the actuator housing, ideally at a suitable metal cable gland.

Signal cables should be routed separately from power and switching conductors.