- 48 -

INST

ALLA

TION

INSTALLATION

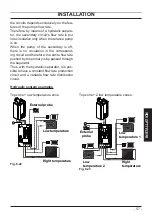

Fig. 6.1

25

25

All measurements are in mm

250

200

•

When installing the boiler in a cupboard,

cover or alcove allow at least 5 mm per

-

manent clearance from the front face of

the boiler. Also ensure sufficient clearance

to allow free access for servicing.

•

Before installing the boiler on an existing

C.H. system, flush it out thoroughly before

fitting the boiler, so as to remove system

debris.

It is advisable to equip the system with a

quality magnetic system filter, you should

also use a water-treatment product in the

circulating water.

The latter option in particular, has an anti-

corrosive effect by promoting formation of a

protective skin on metal surfaces and neu

-

tralising gases present in the water.

We recommend the use of a suitable Build

-

cert approved universal inhibitor to protect

the C.H. system from corrosion.

Biasi UK strongly recommend that matched

system chemicals are used, this will ensure

that no unwanted chemical reactions take

place as system chemical manufactures en

-

sure own brand compatibility,

6.3 Installing the bracket

Precautions

Before mounting the bracket, check that the

dimensions for fitting the flue system are

complied with (refer to the leaflet included

with the flue kit, packed separately).

Utilise the paper template supplied with the

boiler to determine the fixing position for

the bracket and boiler. Securely mount the

bracket to the wall using appropriate fixings

suitable for the type of wall construction and

capable of supporting the total (wet) load.

Refer to the weight given in the technical

data tables specific for each model.