- 12 -

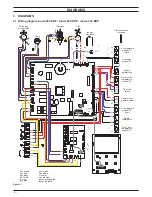

FAult Finding

Co

mp

on

ents

to

ch

ec

k

Sectio

no

ft

he

man

ual

→

(not

er

ef

.i

nb

rackets)

----

---

---

--

(7

)

2.

912

.9

11

.0

2

18.4

617

1

15.2

4.

112

.2

15

.4

1

10

9.

5

14.3

2.

72

.8

65

--- (4

)

21.1

--- (3

)

--- (2

)

--- (1

)

Appl

ianc

eloc

k- --ou

t(*)

Externaltemp

.p

robe

Pressu

regaug

e

Safe

tyva

lve

Expans

ion

vesse

l

Flue

temp.p

robe

NTC

Gas

restricto

r

Safe

tyth

ermostat

Detection

electro

de

Ign

ition

ele

ctrode

Fan

/ai

rrestricto

r

By---p

ass

val

ve

D.h.

w.temp

.p

robe

Main

circui

ttemp.

prob

e

D.h.

w.fi

lter

Main

circui

tp

ressu

reswitch

Gas

val

ve

Cont

rolp

anelel

ectr.p

.c.b.

Boiler

setting

s

Main

electronic

p.c.

b.

Fuse

s(El

ectronicp.

c.b.

)

D.h.

w.fl

owsw

itch

Diverter

valv

e

Pump

D.h.

w.heat

exchanger

Conden

sing

heatexchange

r

D.h.

w.circ

uit

C.h.

circui

t

Cond

.d

rainpi

pean

dtra

p

Flue

pipe

s

Gas

suppl

ylin

e

Powe

rs

upply

lin

e

De

fe

ct

↓

Th

eb

oiler

do

es

no

ts

tart

either

in

c/

ho

rd

.h.w

.m

od

e.

Th

ec

on

trol

pane

ld

is

pl

ay

OF

F

Fa

ns

till

.

Th

eb

oiler

do

es

no

ts

uppl

yd

.h.w

.

(cold

wate

rf

ro

mt

he

ta

p)

.

Regu

la

ro

pe

ration

in

c/

hm

od

ee

ve

n

du

ring

ad

rawing

of

fd

.h.w

.

dis

play

On

c/

hm

od

et

he

temp

eratur

eo

f

th

em

ai

nc

ircu

it

reache

s9

0

Ca

nd

th

ec

/h

sy

st

em

do

es

no

th

eat

.

Th

eb

oile

ro

pe

rates

co

rre

ctly

on

d.h.

w.

mo

de

.

ondi

Inc

orrec

tm

od

ul

at

io

n

tio

no

No

is

yb

olie

r

dic

ati

Poor

c.

h.

/d

.h.w

.t

em

pe

rature

(9

)

”Er”

ind

Po

or

d.h.

w.

temp

erature.

Regu

la

r

op

eratio

ni

nc

/h

mo

de

.

(8

)

No”

Lo

wd

.h.w

.f

lo

wr

at

e

---

Wa

te

rl

eaks

from

th

es

afet

yv

al

ve

duri

ng

op

eratio

no

nc

/h

---

Wa

te

rl

eaks

from

th

es

afet

yv

al

ve

when

th

eb

oi

le

ri

so

ff.

*L

oc

ko

ut

is

in

di

cate

da

s“

E

”o

nt

he

di

sp

la

y.

No

te

Useful

in

format

io

nc

an

be

ob

ta

ined

also

from

th

e

op

tica

li

ndic

at

io

ng

iven

by

th

ea

ppli

an

ce

di

spla

y

(see

sect

io

n4

.1).

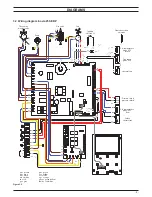

1C

he

ck

fo

r2

30V

~b

etween

line

(L

)a

nd

neut

ra

l(

N)

Ve

rify

th

ei

nt

egrity

of

su

pp

ly

ca

bl

e,

pl

ug

an

de

xt

erna

lf

us

es

.

Ch

ec

kt

he

po

la

rity

of

line

and

neut

ra

lc

on

ne

ctio

n

2C

he

ck

th

eg

as

su

pp

ly

pi

pe

an

di

sola

tion

ta

pf

or

ga

st

ig

ht

ne

ss.

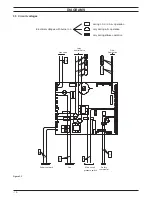

3C

he

ck

fo

rs

ou

ndne

ss

and

ab

se

nc

eo

fo

bs

truc

tion

s.

Ve

rify

th

at

th

ef

lu

et

erminal

is

correctly

in

st

al

le

d(

se

ec

le

aran

ces)

an

de

n-

su

re

th

at

exhaus

tg

as

is

no

ts

uc

ke

db

ac

kb

yt

he

bo

iler

.

4C

he

ck

fo

rs

ou

ndne

ss

of

th

ec

ircu

it

an

dv

erif

yi

ts

correct

fillin

g

(see

al

so

in

st

al

la

tion

ma

nua

l).

5A

ja

mmed

by

---p

as

sc

ou

ld

ca

us

et

he

over

---

heat

in

go

ft

he

ma

in

circ

ui

ta

nd

th

ei

nt

erventio

no

ft

he

sa

fe

ty

th

ermostat

.

6U

si

ng

th

ef

lu

ea

na

ly

ze

r,

ch

ec

kt

he

CO

2

val

ue

of

th

ef

lu

e

gas

es

.

Th

is

readin

gi

sa

referenc

ev

al

ue

fo

rt

he

ga

sv

al

ve

settin

g.

7C

he

ck

th

ep

re

ssu

riza

tion

of

th

ee

xpan

sion

ve

ssel

.R

efer

to

th

e

in

st

al

la

tion

ma

nual

fo

rp

rope

rv

al

ue

s.

8d

.h.w

.p

re

ssu

re

to

oh

ig

ho

rf

lo

wr

at

et

oo

hi

gh

.I

fn

eces

sa

ry

in

-

sert

af

lo

wr

at

el

imiter

(14.6)

.

9T

he

bo

iler

do

es

n’

tr

each

th

en

ominal

heat

in

pu

t.

faul

t findin

G

Summary of Contents for Inovia 25C ERP

Page 2: ......