- 55 -

INST

ALLA

TION

COMMISSIONING

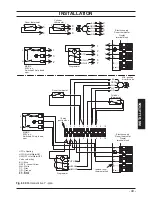

Fig. 7.6

•

Open the gas cock

•

Make sure that the ambient thermostat is in

the “heat request” position”.

•

Check the correct functioning of the boiler

both in domestic hot water mode and in

heating mode.

•

Check the gas pressures and flow rates as

shown in section "GAS CONVERSION" on

page 67 of this booklet.

•

Check that the condensate produced during

functioning fills the syphon

and is regularly

drained in the

draining pipe

.

•

Switch off the boiler by pressing the 13 (Fig.

7.5) key for 2 seconds until the

symbol appears on the LCD display (Fig.

7.4).

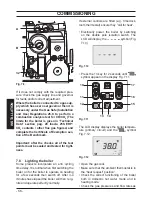

7.5 Condensate pipe and traps

The full length of the condensate pipe should

be check for leaks.

Before running the boiler, ensure that the built

in condensate trap and any other trap in the

drain system is correctly filled with water.

Fill the built in condensate trap by

removing the flue elbow and pour

-

ing a cupful of water into the flue

outlet (Fig. 7.7).

Warning do not allow water to en-

ter the outer air intake.

Fig. 7.7

An alternative, to the removal of the flue el

-

bow, pour the water through the flue sampling

point (Fig. 7.8).

Fig. 7.8

Sampling points

Flue exhaust

7.6 Checking the gas supply pres-

sure

This boiler has been factory tested to the

highest quality control standards and set

for the minimum and maximum gas work

-

ing pressures, connected to a 1 m flue and

a gas supply pressure of 20 mbar.

Any variation in gas supply pressure or

flue length may result in the customer ex

-

periencing a harmonic noise from the boil-

er. In these circumstances, it may be nec-

essary to reset the burner gas pressures

in accordance with section 11 Gas Valve of

the Service Manual.

It should be noted that a Flue Gas Analyser

is required for this procedure.

7.7 Checking the inlet pressure

•

Remove the boiler front panel, see

section

"Dismantling the external panels" on page

70.

•

With the boiler switched on at full rate (maxi

-

mum output power), check the supply pres

-

sure by using the 32 point in Fig. 7.9

and

compare the value with that reported on the

Gas supply pressure table (minimum inlet

pressure) in the "Technical Data" section

(pag. 28

Inovia 25S ERP

.

•

Ensure the test nipple 32 in Fig. 7.9 is firmly

closed.