SAFETY DEVICES

The Thalia board provides:

- one

STOP

command input;

- one obstruction sensing device input

UL

3

25-2016

compatible,

SAFE 1

with its

mandatory supervision circuit input

FAULT 1

. The system reacts to the input in both

opening (stops) and closing (reverses) cycles;

- two programmable obstruction sensing device inputs,

SAFE 2

and

SAFE 3

, both

provided with their optional supervision circuit input

FAULT 2

and

FAULT 3

.

All the

3

safety inputs are

N.C. (normally closed)

contacts. All the FAULT inputs are

N.O. (normally open)

contacts. Below is a table with the terminal numbers and their

corresponding functions and default values.

Terminal

Name

Description

Default

Notes

70

COM

Safety positive common

Common

71

STOP

Stop command

STOP

Overrides all other commands

72

SAFE 1

Safety input #1

PHOT

Stops operators during opening, reverses on closing

73

FAULT 1

Supervisory circuit for SAFE 1

FAULT

Requires opposite relay state from SAFE 1

74

SAFE 2

Safety input #2

006 - BAR

Programmable input (see LOGIC sub-menu)

75

FAULT 2

Supervisory circuit for SAFE 2

FAULT

Requires opposite relay state from SAFE 2

76

COM

Safety positive common

Common

77

SAFE 3

Safety input #3

015 - SHADOW

Programmable input (see LOGIC sub-menu)

78

FAULT 3

Supervisory circuit for SAFE 3

FAULT

Requires opposite relay state from SAFE 3

VALUE

FUNCTION

DESCRIPTION

000

PHOT

System reacts to the input in both opening (stops) and closing (reverses) cycles

001

PHOT TEST

Same as above. Requires the device to be supervised (FAULT active)

002

PHOT OP

System reacts to the input only during the opening cycle (stops)

003

PHOT OP TEST

Same as above. Requires the device to be supervised (FAULT active)

004

PHOT CL

System reacts to the input only during the closing cycle (reverses)

005

PHOT CL TEST

Same as above. Requires the device to be supervised (FAULT active)

006

BAR

Safety edge input. It reacts in both opening and closing. It stops and partially reverses

007

BAR TEST

Same as above. Requires the device to be supervised (FAULT active).

008

BAR 8K2

Safety edge input with EOL resistor as supervision method.

Active only on SAFE 2

009

BAR OP

Safety edge input. During opening it stops and partially reverses. During closing it stops.

010

BAR OP TEST

Same as above. Requires the device to be supervised (FAULT active)

011

BAR OP 8K2

Safety edge input with EOL resistor as supervision method. During opening it stops and partially reverses.

During closing it stops.

Active only on SAFE 2

012

BAR CL

Safety edge input. During closing it stops and partially reverses. During opening it stops.

013

BAR CL TEST

Same as above. Requires the device to be supervised (FAULT active)

014

BAR CL 8K2

Safety edge input with EOL resistor as supervision method. During closing it stops and partially reverses.

During closing it stops.

Active only on SAFE 2

015

SHADOW

Safety loop input. If the contact is closed, it prevents any movement of the leafs when gate is open (VALUE 0 of the

LOGIC

SHADOW

) or when the gate is both open and closed (VALUE 1 of the

LOGIC

SHADOW

). See chart example N. 3 on next page.

Both

SAFE 2

and

SAFE 3

can be programmed to perform any of the following functions under the

LOGIC

sub-menu:

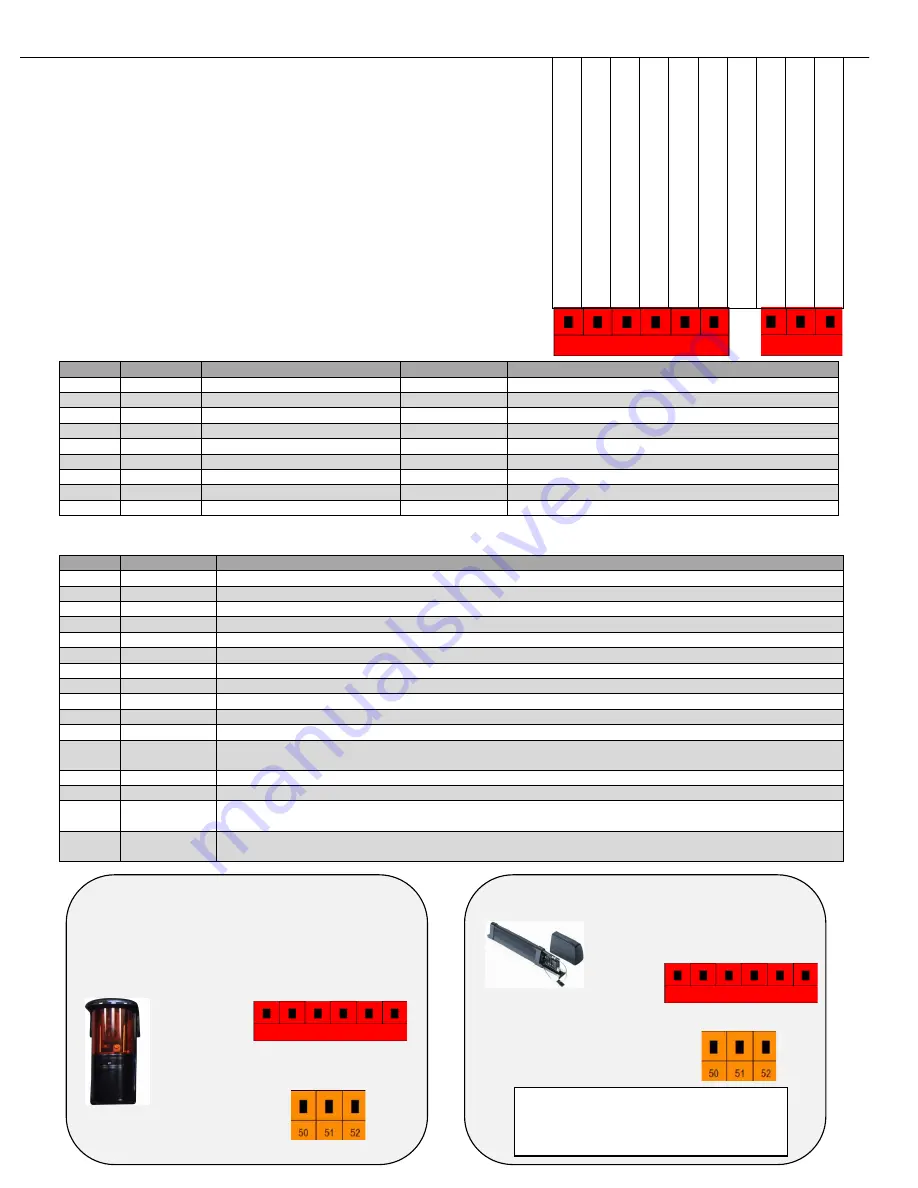

EXAMPLE 1

: UL

3

25-201

6

SAFETY PHOTO BEAM SENSOR WIRING

RELAY N.

O

.

RELAY N.C.

COMMON

POWER 24V +

POWER 24V -

EXAMPLE 2

: SAFETY EDGE WIRING

RELAY N.C.

COMMON

PROGRAMMING

:

LOGIC > SAFE 2 > 006 (BAR)

7

0

-

C

o

m

m

o

n

7

1

-

S

T

O

P

72

–

SAFE

1:

PHOT

UL

3

25-16

(obstruction)

73

–

FAULT

1

UL

3

25

-

2016

7

4

–

S

A

F

E

2

–

p

ro

g

ra

m

m

a

b

le

-

d

e

fa

u

lt

i

s

BA

R

(s

a

fe

ty

e

d

g

e

)

7

5

–

F

A

U

L

T

2

7

6

-

C

o

m

m

o

n

7

7

–

S

A

F

E

3

–

p

ro

g

ra

m

m

a

b

le

–

d

e

fa

u

lt

i

s

S

H

A

D

O

W

(

sa

fe

ty

l

o

o

p

)

7

8

–

F

A

U

L

T

3

76 77 78

20

70

71

72

73

74

75

70

71

72

73

74

75

70

71

72

73

74

75