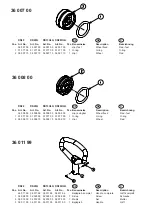

DK20, DK20Q, DK13HLQ

DK20HLQ

WARNING -

safe usage instructions

1.

Study, understand and follow all instructions before

operating this jack.

2.

Do not exceed rated capacity.

3.

Use only on hard level surface.

4.

It is recommended to brake and chock the vehicle.

5.

Do not move or transport the vehicle while on the

jack.

6.

Lifting device only. Immediately after lifting, sup-

port the vehicle with support stands.

7.

Lift only on areas of the vehicle as specified by

the vehicle manufacturer, and only centrally on the

lifting saddle.

8.

No person shall remain in, on, or get bodily under

a load that is being jacked or is supported only by

a jack.

9.

Only original accessories and spare parts shall be

used.

10.

No alterations shall be made to this jack.

11.

Failure to follow these warnings may result in per-

sonal injury and/or property damage.

Assembly

Mount plastic handle on tube lever with inner projec-

tion to fit into slot. Push tube lever into handle until

screw and nut can be mounted (use a rubber hammer

to adjust handle position).

Then place lever in tipping gear, and secure it with tip-

ping gear screw fitting into slot in tube lever.

Use

Lifting:

Activate lever tube up and down using full

strokes.

Lowering:

Pull lever tube up, then slowly turn counter

clockwise.

Maintenance

Maintenance and repair must always be carried out by

qualified personnel.

Daily:

Inspect jack for damages.

Monthly:

Lubricate all mechanical parts with a few

drops of oil.

Oil refill:

Pump with cylinder is a closed system and

refilling of oil is normally not necessary. In order to refill

oil it is necessary to demount the hydraulic unit:

GB

1.

Unfasten screw (23) through hole in base frame.

2.

Release and lower the jack completely.

3.

Keep lever vertically and block piston rod (34) in the

inmost position by means of a screw or nail through

hole in release bracket (42). Mind the inner spring!

4.

Remove lever tube and tipping gear as well as the

two screws (6) on top of lifting frame.

5.

Now the hydraulic unit is loose and can be removed

up front from the lifting frame.

6.

Assembly takes place in reverse order. Pump the

jack half-way up in order to ease mounting of the

last screw (23).

Correct oil level is up to lower edge of filling hole (27)

with the cylinder vertical and the piston rod pushed

completely in. Too much oil causes poor pumping.

Quantity of oil:

DK20, DK20Q and DK13HLQ:

0,3 l.

DK20HLQ:

0,5 l.

Any good hydraulic oil of viscosity ISO VG 15 can be

used.

Never use brake fluid!

Safety Inspection

According to national legislation - minimum once a

year though - the jack must be inspected by a profes-

sional: damages, wear and tear, adjustment of the

safety valve, hydraulic unit for leakages.

Possible faults and how to overcome them

1.

The load is dropping occasionally: Verify the play

between release bracket (42) and lever tube. Adjust

the two nuts (10) until the play is 1-2 mm, irrespec-

tive of the lever tube position (vertical or horizontal).

2.

The jack does not lift to maximum position: refill

with oil.

3.

The load is dropping: leaking pump valves or worn

seals. Inspect the valve seats + balls under plug

(30) and change seals in lifting cylinder.

4.

The hydraulic unit is leaking: exchange worn seals

with repair kit 0906000.

Spare parts

Replace worn or broken parts with genuine jack manu-

facturer supplied parts only. All major parts may not be

provided after discontinuation of a model.

Destruction

Oil must be drained off and legally disposed of.