20. Slide the Top Guide Sleeve (Key No. 20) over the

Shaft and rest it on the Thrust Washer.

21. Slide the Shaft Lock Washer (Key No. 21) onto the

Top Guide Sleeve and lock it with an M8 Allen Screw

(Key No. 6).

22. Install the Standard Guide Housing (Key No. 9). Seat

it on the Delivery Stage Plate (Key No. 17) by gently

tapping it with a rubber mallet.

NOTICE: The bearing is not centered end-to-end in

the Guide Housing. Make sure that the Guide Housing

goes on to the Shaft with the short (9.25mm or 3/8”)

end of the Guide Housing going first, as shown in the

exploded view, Page 10.

23. Mount the Discharge (Key No. 24) on the Guide

Housing by gently tapping it with a rubber mallet.

24. Hook the four Straps (Key No. 25) onto the Discharge

and fasten them to the Suction Bracket Assembly with

Lock Washers (Key No. 27) and M12 Hex Head Bolts

(Key No. 28).

NOTICE: Tighten the four Straps evenly to 6.5 kgm

(47 ft.-lbs.) torque.

25. Install the Outer Strainer (Key No. 29) and Cable

Guard (Key No. 30) with two 4 mm Washers (Key No.

31) and M4 Screws (Key No. 32).

26. Remove the pump from the fixture.

27. Check the axial clearance of the pump shaft (2.5 mm

to 3 mm. or 3/32” to 1/8”).

The pump is ready for installation.

Table VI: Intermediate Guide Housing Locations

Number of

Number of

Stages

Guide Housings Required

0 - 12

0

13 - 24

1 at Midpoint of Shaft

25 - 37

2 at 1/3 and 2/3 Length of Shaft

Space Intermediate Guide Housings evenly.

9

PREVENTIVE MAINTENANCE

To avoid major repairs, make the checks listed below every 4 to 6 months.

TEST

1.

Measure and record the standing

water level (from top of well

casing).

2.

Measure electrical resistance

between motor leads and well

casing with motor cold.

3.

Check pump flow capacity

(gallons per minute).

4.

Check pump discharge pressure

(PSI) at operating conditions.

5.

Check drawdown level (in feet)

from standing water level.

6. Measure voltage across motor

leads while pump is operating.

RESULT SHOULD BE

1. Reference number.

2.

See motor manual.

3.

At least 90% of readings at

installation.

4. At least 90% of readings at

installation.

5. High enough so that pump does

not break suction.

6.

Within ±10% of rated voltage.

POSSIBLE INDICATIONS

1.

To aid in monitoring pump

performance.

2.

See motor manual.

3.

Lower readings may indicate

pump needs repair.

4.

Lower reading indicates pump

wear, increased friction losses, or

change in standing water level in

well.

5.

Cavitation can damage pump;

increased drawdown may

indicate reduced well flow.

6.

If voltage is more than 110% or

less than 90% of rated voltage,

consult power company.

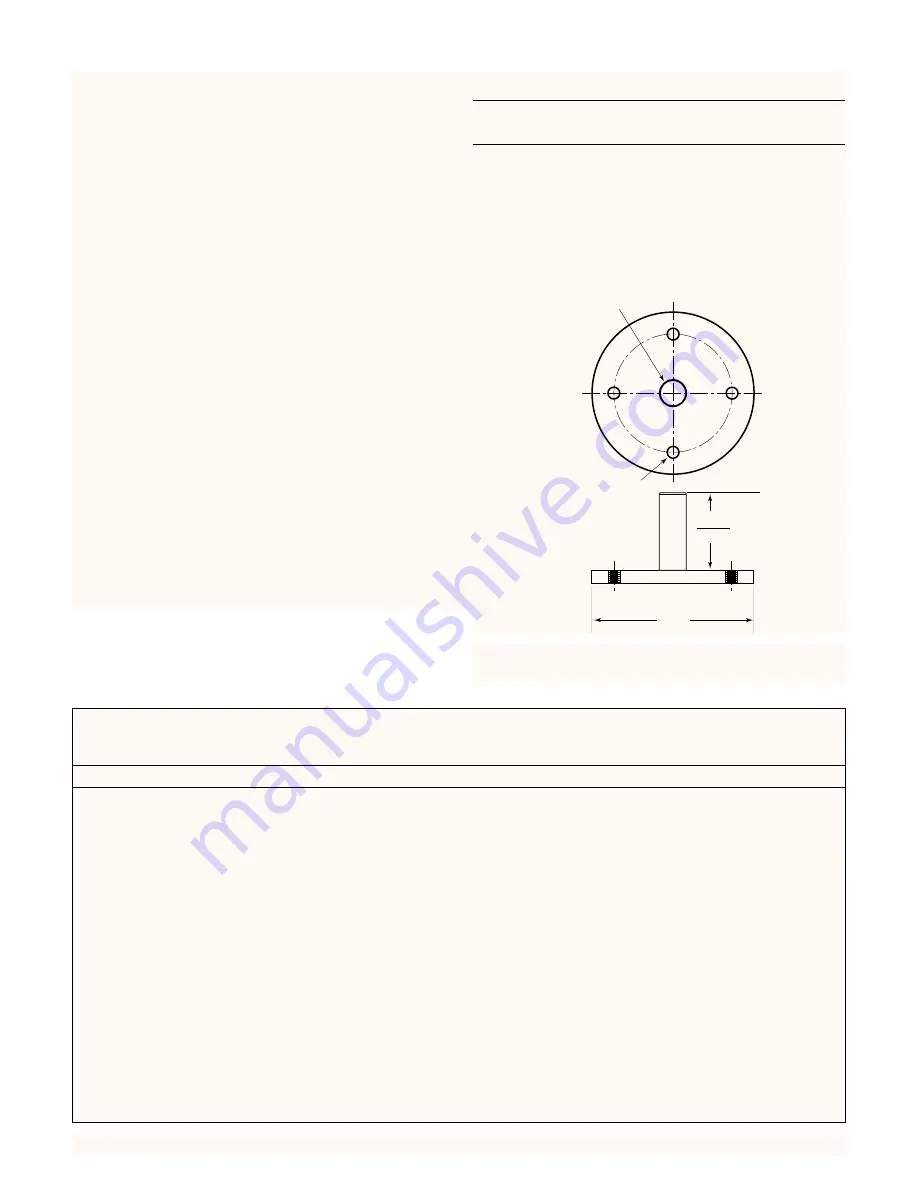

2.875"

2.869"

6.0"

1/2 - 20 UNF-2B

4.38" DIA. B.C.

4 Holes

1.00" Dia.

Figure 8: Assembly fixture dimensions for 6” motor;

stickup is motor height.