Anchor power cable to pipe every 20 feet with adjustable

steel band clamps. Protect insulation from clamps with

pieces of split rubber hose inserted between clamps and

cable. Attach cable to pipe halfway between clamps with

waterproof tape (Scotch No. 33 or equivalent).

Submergence

Be sure the pump is always submerged, even at extreme

pumping rates. Install pump at least 10 to 20 feet below

the lowest "drawdown" water level and at least 5 feet

above bottom of well.

Check Valves

Every 6S/E6S pump is factory equipped with an internal

check valve in the pump discharge. No additional check

valve is required near the pump.

Install check valve in discharge pipe, not more than 25 feet

above pump. For 6" and larger submersible pumps

installed more than 600 feet deep, install a second check

valve at the pipe joint nearest to the half-way point

between pump and ground level.

NOTICE: To avoid water hammer and pipe breakage,

distance from first check valve to second check valve

should not equal distance from second check valve to

ground level.

Well and Pump Test

Check and record static water level of well before starting

tests. Before making final piping connections, test flow

rate, capacity, and condition of well.

NOTICE: Do not operate pump with discharge valve

closed. Operate pump only within pressure and flow limits

of operating range established by performance curve.

NOTICE: If sand is present in discharge, allow pump to

run with discharge completely open until water is clear. If

loud rattling noises develop, pump is probably cavitating.

Gradually close discharge valve until rattling stops.

INSTALLATION -

ELECTRICAL TESTS

Risk of high voltage electrical shock

when testing. Can stun, burn, or kill.

Only qualified electricians should perform these tests.

When testing, use all normal precautions for the

voltages involved.

Electrical test of motor, cable, connections

The cable and splices can be damaged as the pump is

lowered into the well. To electrically test them, attach one

lead of ohmmeter to pipe. Attach other lead to each cable

lead in turn. See motor owner's manual for required

resistance in a good motor. A low reading indicates that

cable or splice has developed a leak to ground. Remove

pump from well and correct problem before proceeding

with installation.

Measure electrical resistance between motor leads and

well casing when motor is cold.

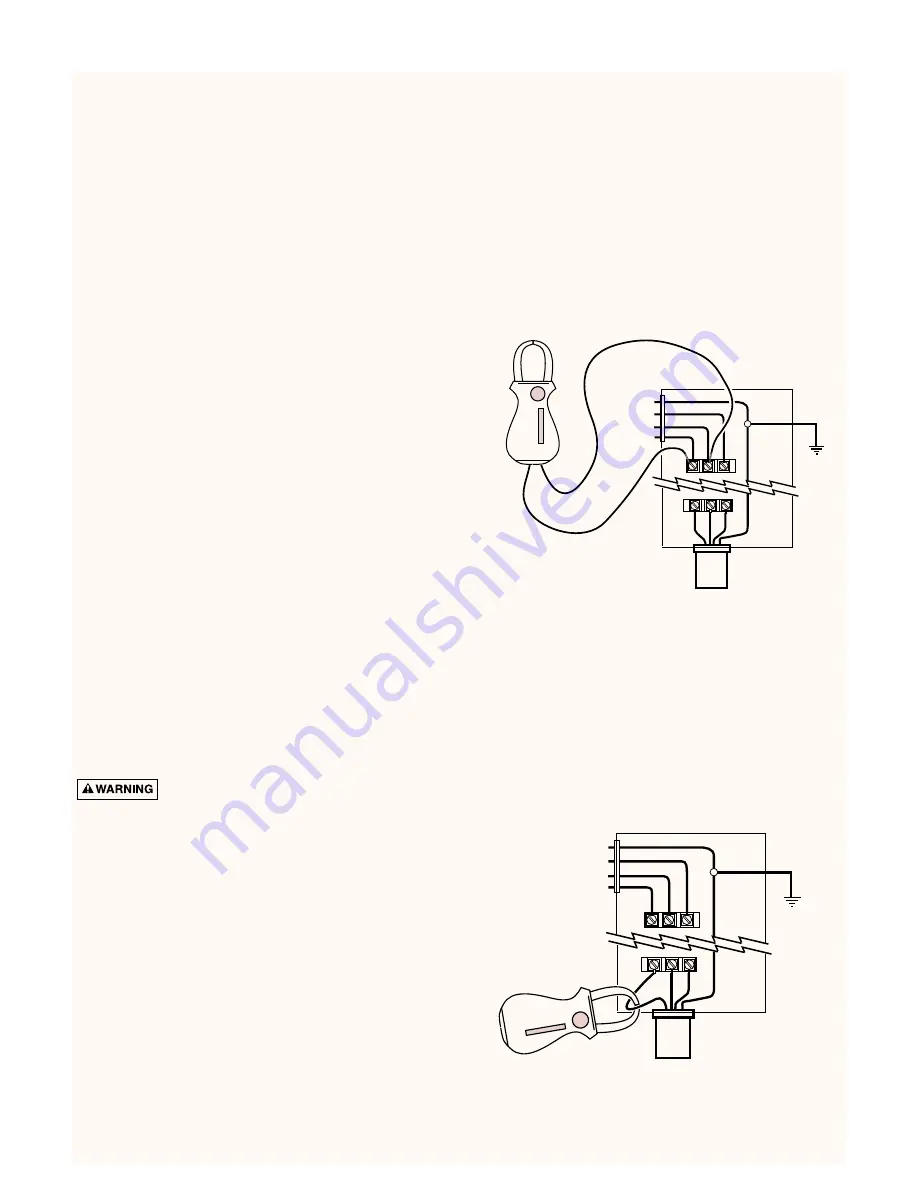

Voltage test (Figure 2)

Low or high voltages can cause motor failure. While pump

is operating, check voltage across each pair of leads at

motor controller. Readings more than 10% above or below

rated nameplate voltage can damage pump; correct before

placing pump in service. Test as follows:

1. Disconnect main power supply and open controller.

2. Connect power and start pump. For 3-phase motors,

read voltage across three pairs of leads (L1 – L3, L3 –

L2, L2 – L1) while pump is operating. For single phase

motors, read voltage across L1 and L2 while pump is

operating. Voltage should be within ±10% of motor

nameplate rated voltage. If not, consult power

company.

Load current test (Figure 3)

Load current should be obtained on each motor lead at the

controller. Partially close pump discharge valve (keep

pressure and flow within specified operating range) until

maximum amp reading has been obtained. Compare

reading with motor nameplate rating. If reading is 15% or

more over rated load, check for incorrect voltage in supply

line or overload due to abrasives in pump. Find and correct

problem before putting pump in service.

4

L3

L2

L1

G

To Pump

Incoming

Power

Ground

Controller

Figure 2: Voltage Test

L3

L2

L1

G

To Pump

Incoming

Power

Ground

Controller

Figure 3: Load Current Test