14

MYNUTE X R

3.19 Access to the parameters

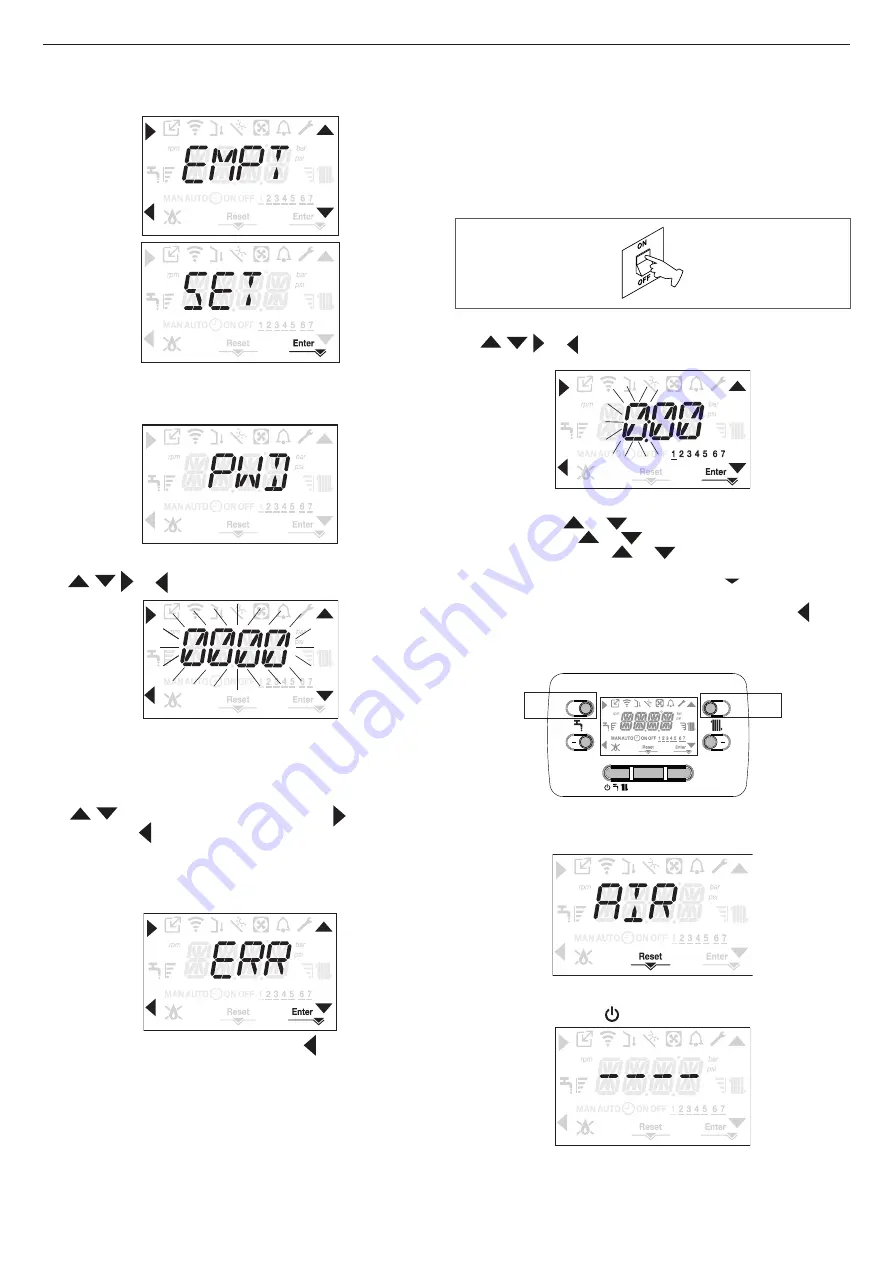

Pressing the MENU key for at least 2 sec provides access to the settings menu, allowing the

parameters to be programmed. If the menu is empty, EMPTY MENU is displayed, otherwise

the first item in the menu appears.

Access to the TECHNICAL parameters programming menu is password protected; pressing

MENU a second time for at least 2sec, PWD is displayed blinking with a frequency of 0.5sec

ON and 0.5sec OFF for 2sec.

Then <<0000>> is displayed blinking with a frequency of 0.5sec ON and 0.5sec OFF; the

icons

,

, and come on to allow the password to be entered.

There are two levels of access to the parameters:

- INSTALLER

- SERVICE

(the user level does not require a password).

Set the password supplied by the manufacturer for the desired access level using the button

at the

,

arrows to enter the value. Press the key

A

at the

arrow to confirm.

Pressing key

B

at the arrow returns you to the previous level, exiting the settings menu.

It is now possible to navigate the menu using the

C

and

D

arrow keys, confirming access

to the sub-menu with arrow key

A

or else returning to the previous level using arrow key

B

.

Note: The ERR message indicates that the selected menu item or parameter are not

available for the boiler model you are using:

Prolonged pressure at any point of the menu (>2sec) of the key returns you to the main

page. The interface also reverts automatically to the main screen if no key is pressed within

60sec.

4 COMMISSIONING

4.1

Preliminary checks

First ignition is carried out by competent personnel from an authorised Technical Assistance

Service Beretta. Before starting up the boiler, check:

- that the data of the supply networks (electricity, water, gas) correspond to the label data

-

that the extraction pipes of the flue gases and the air suction pipes are working correctly

- that conditions for regular maintenance are guaranteed if the boiler is placed inside or

between items of furniture

- the seal of the fuel adduction system

-

that the fuel flow rate corresponds to values required by the boiler

-

that the fuel supply system is sized to provide the correct flow rate to the boiler, and that

it has all the safety and control devices required by current regulations

- that the circulator rotates freely because, especially after long periods of inactivity,

deposits and/or debris can prevent free rotation. See paragraph "3.11 Manual reset of

the circulator".

4.2

Programming the boiler

- Position the system’s master switch to the “on” position.

If necessary, the interface automatically goes to the

clock menu

. On the main screen the

icons

,

, and

and ENTER come on while 00:00 is displayed with the first two

digits blinking with a frequency of 0.5 sec ON, 0.5 sec OFF.

To set the time and day follow the following instructions:

set the hour with the

and

arrows, then confirm with

A

set the minutes with the

and

arrows, then confirm with

A

set the day of the week with the

and

arrows. The segment in line with the day

selected blinks, press the menu MENU key at the icon

Enter

to confirm the time and

day setting. The clock blinks for 4sec and then returns to the main screen

to exit the time programming without saving the modified values just press .

NOTE: It is possible to change the TIME and DAY settings also later by accessing the TIME

parameter in the SETTING menu, or by pressing the

A

+

C

keys for at least 2sec.

RESET

+

MENU

+

C

A

Each time that the boiler is powered a vent cycle is carried out lasting 6 min. The display

shows the message VENT AIR PURGING CYCLE IN PROGRESS lighting up the icon

RESET.

To interrupt the vent cycle press RESET.

Set the boiler to OFF by pressing

.

Using the interface it is possible to access, using the SETTINGS menu, a series of

parameters that can be programmed to allow you to personalise the operation of the boiler

based on the type of system. Set the parameters according to the desired operating modes.