28

TECHNICAL ASSISTANCE CENTRE

14 TEMPORARY SHUTDOWN

If you are going away for a short period of time like a

weekend or a short holiday, etc., and outdoor temperatures

are going to remain above ZERO, proceed as follows.

- Adjust the storage cylinder thermostat to its minimum

setting.

b

If outdoor temperature may drop below ZERO (risk

of freezing) perform the operations described in the

“Preparing for extended periods of disuse” section.

15 PREPARING FOR EXTENDED

PERIODS OF DISUSE

If the storage cylinder is not going to be used for an

extended period of time, perform the following operations:

- Cover the solar collectors with suitable protection

- Switch the electricity supply to the storage cylinder’s

valve group and to any associated boiler OFF at the

main switch and at the control panel

- Close the shut-off cocks for the domestic hot water

circuit.

b

Drain the domestic hot water circuit if there is any risk

of freezing.

Contact your local

B

Technical Assistance Centre

if you encounter any problems in completing the above

procedure.

16 MAINTENANCE

Scheduled maintenance is essential for the safety,

efficiency and long working life of your storage cylinder.

Proper maintenance also reduces energy consumption and

ensures reliability over time. Have your storage cylinder

serviced either by the manufacturer’s Technical Assistance

Centre or by a qualified heating engineer at least once a

year.

Perform the following operations before beginning any

maintenance:

- Switch the electricity supply to the storage cylinder’s

valve group and to any associated boiler OFF at the

main switch and at the control panel

- Close the shut-off cocks for the domestic hot water

circuit

- Drain the storage cylinder’s DHW (secondary) water

circuit.

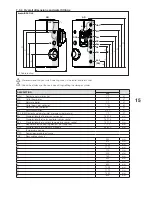

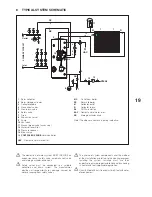

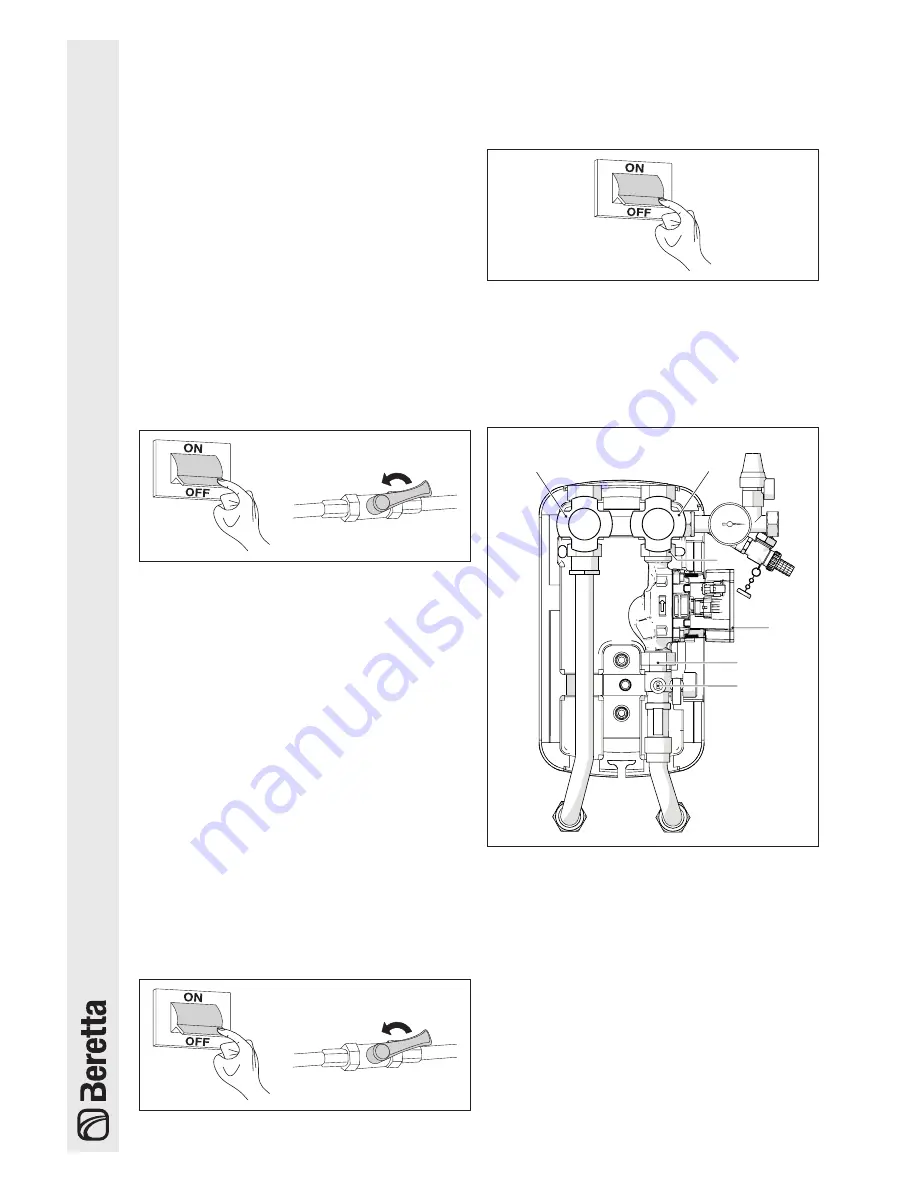

REPLACING THE PUMP

Perform the following operations before starting work to

replace the pump (C):

- Switch the electricity supply to the storage cylinder’s

valve group and to any associated boiler OFF at the

main switch and at the control panel

- Close the flow regulator (V)

- Turn the valve knob 90° clockwise to close the valve

(R)

- Unscrew the ring nuts (H1 and H2) and remove the

pump (C).

Reverse the above steps to fit the new pump.

V

C

R

H1

H2

M

Return

group

Outlet

group

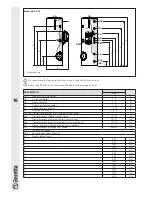

CHECKS TO PERFORM DURING SYSTEM

MAINTENANCE

- Use litmus paper to ensure that the pH of the heat

transfer liquid is not below 7.5

- Use an instrument like a refractometer or densimeter

to check that the heat transfer liquid has not lost its

anti-freeze properties

- Check the controller settings

- Check the position and functioning of the temperature

sensors

- Check the pre-charge in the expansion vessel (2.5

bar)

- Check the functioning of the storage cylinder and

protective anode.