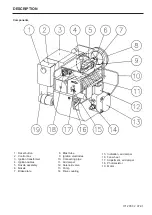

Function Danfoss BFP41

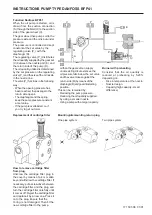

When the oil pump is started, oil is

drawn from the suction connection

(S) through the filter (H) to the suction

side of the gear wheel (C).

The gear wheel then pumps oil to the

pressure side and the oil is put under

pressure.

The pressure is controlled and kept

constant at the set value by the

regulating valve (P

1

) with the

diaphragm (D).

The regulating valve (P

1

) distributes

the oil quantity supplied by the gear set

(C) between the nozzle port (E) and

the return side of the pump (R).

The oil quantity utilized is determined

by the set pressure on the regulating

valve (P

1

) and the size of the oil nozzle

in the nozzle line.

The valve (P

1

) functions in the following

way:

- When the opening pressure has

been reached, the passage to the

return side opens.

- The diaphragm and the spring

keep the pump pressure constant

at set value.

- If the pump is overloaded, i.e. if

you try to get out more

oil than the gear set can supply

under existing circum-stances, the

oil pressure falls below the set value

and the valve closes against the

return side (R) by means of the

diaphragm (D) and goes into starting

position.

This can be remedied by:

- Reducing the pump pressure.

- Reducing the oil quantity supplied

by using a smaller nozzle.

- Using a pump with a larger capacity.

171 505 08 07-01

Replacement of cartridge filter

Burner with preheating

Consider that the oil quantity is

reduced at preheating by 5-20%

depending on.

- Rise in temperature at the nozzle

- Nozzle design

-

Capacity (high capacity - small

difference)

Mounting/dismounting return plug

How to remove cartridge filter

from plug

Unscrew the cartridge filter plug in

the cover by means of a 4 mm allen

key and withdraw the cartridge filter. If

necessary, put a screwdriver between

the cartridge filter and the plug and

turn the cartridge filter carefully until

it comes off. Reject the cartridge filter

and replace it by a new one. Press it

on to the plug. Ensure that the

O-ring is not damaged. Then fit the

new cartridge filter to the pump.

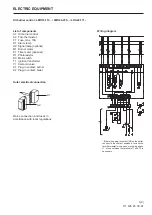

One pipe system

Two pipe system

R

S

E

NC

A

G

H

V

P

1

P

D

C

INSTRUCTIONS PUMP TYPE DANFOSS BFP41