1210SHH_AMEN,page 12/29

Attention: Serious damage can occur to burner

relay when faulty connection of thermostat, reset

switch or burner failure lamp. Switching of wires

for reset switch and flame failure (e.g. in a remote

control box) will destroy the burner relay.

GAS CONNECTION

Connection to a gas service may only be carried out by

suitably qualified persons. All piping must be in

accordance with requirements outlined in the National

Gas Codes (different for each country). Gas supply

piping installation should also conform to good practice

and any local codes. Support gas piping with pipe

hangers, metal strapping, or other suitable material.

Do not rely on the unit to support the gas

pipe!

All sealing products shall be resistant to the action of

liquefied petroleum gas or any other chemical

constituents of the gas being supplied. Install a ground

joint union and manual shutoff the gas cock upstream of

the unit control system (see figure 9). The unit is

equipped with a nipple that extends outside the cabinet.

The gas connection is 3/4”. Leak test all connections by

brushing on a leak detecting solution. Check that the

gas category is in accordance with the data described

on the air heater. An adequate gas supply sized to

provide the dynamic pressure for the volume required by

the air heater(s) is essential to maintain the nominal

heat input.

Ensure that a gas supply line includes a filter and has

been tested and purged in accordance with prescribed

practice prior to commissioning and taking the air heater

into service.

This appliance is equipped for a

maximum gas supply pressure of

50mbar. Pressure testing supply piping:

test pressures above 50mbar:

disconnect the heater and manual valve

from the gas supply line that is to be

tested. Cap or plug the supply line..

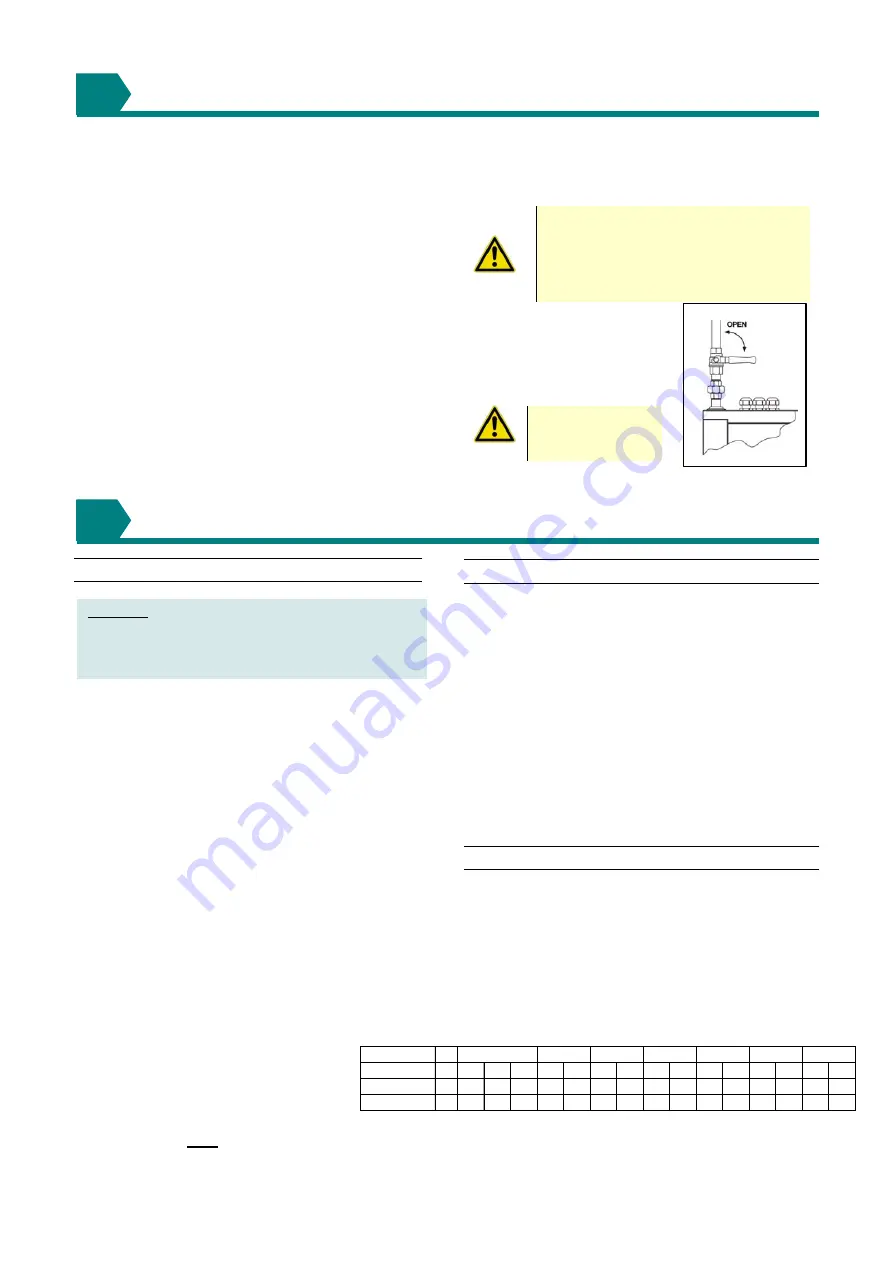

Figure 9 :

Gas connection detail

NEVER use a

FLAME

to test for GAS

SOUNDNESS !

ELECTRICAL CONNECTION

8.1

Electrical supply & connections

The electrical installation may only be carried out by an

appropriately qualified person current to IEE

Regulations. The supply line to the heater should

include a main switch adjacent to the appliance. The

minimum

clearance

distance between the contacts must

be more than 3 mm. All electrical connections should be

made in the heater control compartment (refer to figure

10). Connections should be in accordance with the

terminal markings and the wiring diagram affixed to the

air heater. The minimum external control required for the

air heater is a room thermostat.

It is essential that the

main input line and neutral to terminals L and N

remain live at all times even when the heater is

switched off to ensure correct operation of the unit

and to let the fan operate independent of the heating

control. Never incorporate controls that isolate the

appliance electrically.

A burner reset switch with red indicator light is fitted on

the heater. To add a remote reset button, make

connections to the terminals in the electric box as

indicated on the wiring diagram.

IMPORTANT : If the reset button requires activating

for any reason, the cause must be determined. After

determining and correcting the problem, restart the

heater and monitor long enough to ensure proper

operation (approx. 5 minutes).

Check that the electrical specification is in

accordance with the specified data on the

air heater. A unique appliance wiring

diagram is supplied as a separate document

attached to this one plus an additional copy

attached to the air heater.

These appliances

must

be earthed.

8.2 Thermostat

controls

Ancillary controls are required to provide timed heat

cycles, room comfort temperature level, frost protection,

override air circulation etc. These are not included with

the appliance and should be ordered separately.

Do not attempt to control more than 1 air heater from

a single thermostat or control panel unless a properly

wired relay is fitted. Follow the instructions supplied

with such panels.

The location of the room thermostat or sensor is very

important. It should not be positioned on a cold wall or

cold surface. Avoid location in draughty areas or where it

may be influenced by heat sources e.g. the sun, process

plant, etc. The thermostat should be mounted on a

vibration free surface and mounted about 1,5 metres

above floor level. Follow the thermostat manufacturers

instructions. The thermostat must be suitable for

potential free contacts.

8.3 Fan

motors

The centrifugal blowers fitted to the BSHH/RHH air

heaters are of the forward curved type therefore, the

speed setting for the static pressure imposed by the air

distribution system will govern the motor loading. All

heaters leave the factory with the drives set to the

specified conditions of the appliance. Table 4 provides

the motor characteristics for the various sizes. Refer to

section 9 to learn how to carry out adjustments necessary

to alter the fan speed and motor load factors.

Table 4 : Maximum motor load rating

(1) only possible on 083 model

7

8

Motor rating kW

Phase

~

1

3

3

3

3

3

3

3

3

3

3

3

3

3

3

Voltage

V

230 230 400 230 400 230 400 230 400 230 400 230 400 230 400

Load rating

A

5,2

3,3

1,9

4,5

2,6

5,9

3,4

8,3

4,8

11

6,5

15

8,6

19

11

3

4

5,5

0,75(1)

1,1

1,5

2,2