Fokker

EIII

Page

13

Copyright©

2007

M.K.

Bengtson

All

Rights

Reserved

Rev

07/11

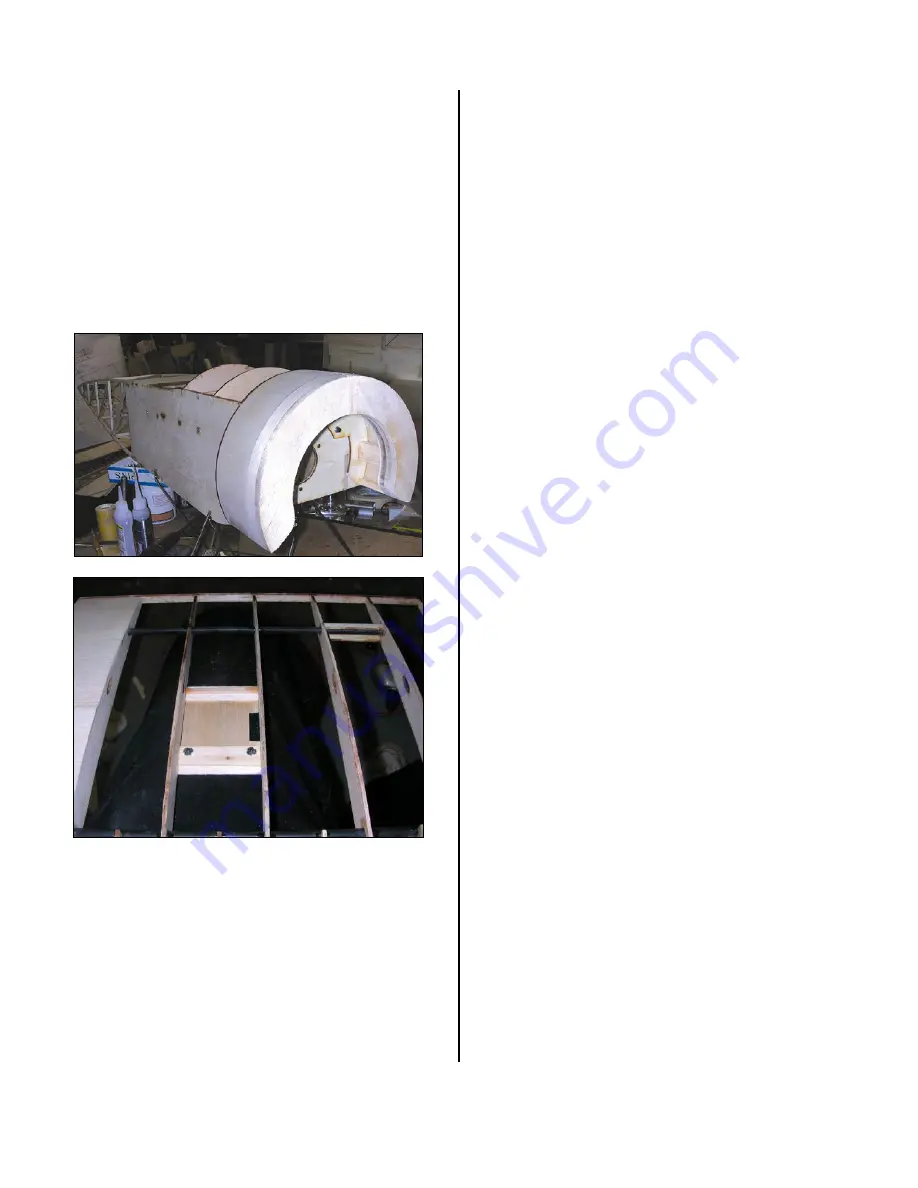

the

front

of

cowl

piece

C2

to

form

the

front

of

the

cowl.

When

this

is

done,

the

front

edge

is

rounded

over

fairly

severely

to

get

the

proper

shape.

I

have

not

yet

started

to

round

over

the

cowl

front.

The

cowl

is

attached

to

the

firewall

using

two

4

‐

40

screws

and

blind

nuts.

The

holes

in

the

firewall

are

the

correct

diameter

for

the

4

‐

40

blind

nuts

so

there

are

installed

there

and

glued

in

place.

I

used

two

4

‐

40

x

3/8

ʺ

long

socket

head

cap

screws

to

hold

the

cowl

in

place.

If

you

look

in

the

photo,

you

can

see

one

of

the

cap

screws.

AILERONS

The

full

size

EIII

used

wing

warping

for

roll

control.

Since

this

is

a

semi

scale

model

and

rigging

up

a

functional

wing

warping

system

would

be

a

bit

of

a

job,

this

particular

bird

was

designed

with

full

span

strip

ailerons.

When

hinged

from

the

top

and

the

hinge

gap

covered

they

should

not

be

too

noticeable

and

it

allows

the

plane

to

retain

the

scale

dihedral

instead

of

the

5

degrees

or

so

per

panel

that

a

rudder/elevator

design

would

require.

The

plan

calls

for

a

Hitec

HS

‐

55

in

each

panel

to

drive

the

aileron

in

each

wing.

I

had

a

couple

of

HS

‐

81

ʹ

s

laying

around

looking

for

an

application

so

I

decided

to

use

them.

As

the

HS

‐

81

ʹ

s

are

a

bit

bigger

I

moved

the

servo

location

back

away

from

the

TE

a

bit

more

to

allow

the

servo

to

fit

easily

within

the

wing

structure.

Two

laser

cut

servo

hatches

from

1/32

ʺ

ply

are

provided

in

the

kit.

As

I

have

a

nasty

habit

of

breaking

these,

I

made

two

new

ones

from

1/16

ʺ

ply.

I

located

the

back

end

of

the

hatch

5

ʺ

from

the

trailing

edge

and

glued

in

a

piece

of

1/16

ʺ

x

3/8

ʺ

balsa

flush

with

the

rib

bottom.

This

will

form

part

of

the

hatch

hold

down

and

also

give

the

covering

something

to

grab

on

to.

I

then

placed

the

hatch

cover

in

place

and

glued

another

piece

of

1/16

ʺ

x

3/8

ʺ

balsa

at

the

other

end

flush

with

the

rib

bottom.

I

then

glued

a

piece

of

1/16

ʺ

x

3/8

ʺ

balsa

to

the

back

end

of

the

hatch

cover

to

form

a

tongue.

This

will

slip

into

a

slot

at

the

back

3/8

ʺ

balsa

piece

to

retain

the

hatch

cover.

The

front

end

gets

held

in

place

with

some

2

‐

56

screws

and

blind

nuts.

I

cut

a

piece

of

1/8

ʺ

lite

ply

9/16

ʺ

wide

and

glued

it

to

the

inside

face

of

the

forward

3/8

ʺ

balsa

piece

allowing

about

3/8

ʺ

or

so

to

extend

into

the

servo

area.

This

forms

the

piece

that

the

blind

nuts

will

attach

to.

I

then

laid

the

hatch

cover

in

place

and

at

the

trailing

edge

end

I

glued

a

piece

of

1/8

ʺ

sq

spruce

on

top

of

the

balsa

tongue

(glue

to

the

ribs

only).

This

forms

the

slot

that

the

tongue

slips

into.

I

then

drilled

two

holes

about

3/16

ʺ

in

from

the

forward

edge

and

about

1/4

ʺ

in

from

the

sides

through

the

servo

hatch

cover

and

the

underlying

1/8

ʺ

lite

ply

plate.

These

are

the

located

for

the

hold

down

screws.

I

then

enlarged

the

holes

in

the

lite

ply

plate

and

installed

2

‐

56

blind

nuts.

The

hatch

cover

can

now

have

the

rear

end

tongue

slipped

into

the

slot

and

the

hatch

held

down

by

the

two

2

‐

56

screws.

The

servo

is

held

in

place

by

two

pieces

of

3/8

ʺ

sq

basswood

each

about

5/16

ʺ

long.

The

servo

location

is

marked,

the

two

bas

pieces

glued

in

place

and

some

triangle

stock

added

to

help

reinforce

the

pieces.

The

mounting

holes

are

then

drilled

and

the

servo

is

screwed

in

place

using

the

2

‐

56

servo

mounting

screws

that

Micro

fasteners

sells.

These

are

the

2

‐

56

Socket

Head

screws

with

the

integral

washer.

These

are

great

items

by

the

by.