27

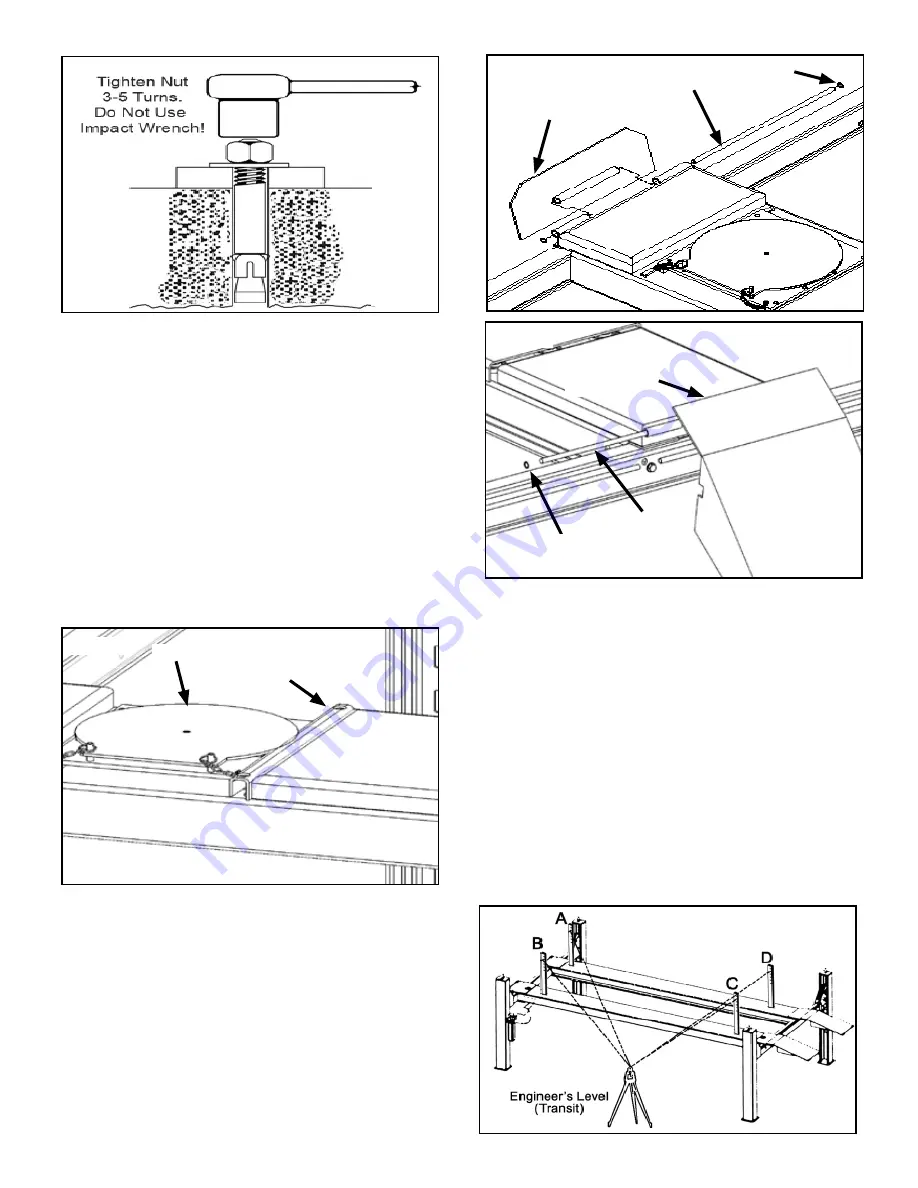

6. With the Shims and Anchor Bolts in place, tighten Nut

three to five turns past finger tight. Do not use an Impact

Wrench for this procedure. (See Fig. 14.6)

IMPORTANT !

If Anchor Bolts do hold when torqued to required

amount, concrete must replaced. Saw cut and

remove 24” x 24” square area each Column base

then re-pour with reinforced 2500 PSI concrete to a

depth of six inches minimum, keying new concrete

under existing floor.

STEP 15

(Installing Accessories)

1. Place the Turnplates in the Turnplate pockets. Insert

the Rollback Spacer Bars between the Turnplate and ris-

ers as needed for alignment procedures. (See Fig 15.1)

2. Install the Front Tire Stops using the Hinge Pins and

rotor-clips as shown. (See Fig. 15.2)

3. Install the Drive-Up Ramps using the Hinge Pins and

rotor-clips as shown. (See Fig. 15.3)

STEP 16

(Leveling / Sychronizing)

1. Using an Engineer’s Automatic Level (transit), locate

the Level, at a convenient location in the shop that allows

an unobstructed view of all four corners of the runways.

2. Follow the Level manufacturer’s instructions for proper

setup of the Level. Be sure it is adjusted level in all direc-

tions.

3. Raise the lift approximately 30”- 40”. Then lower the

lift until all Primary Safeties are completely resting on the

same Safety Ladder position on all Safety Ladders.

4. Place a Level target on the right/front corner of the

ramp. (See Fig. 16.1)

Fig 14.6

Fig 15.2

Hinge Pin

Rotor Clip

Tire Stop

Fig 15.1

Turnplate

Rollback

Spacer

Fig 15.3

Hinge Pin

Drive-Up

Ramp

Fig 16.1

Rotor Clip