Installation and operation instructions US-EN

12

DRYPOINT

®

M intelligence

The control software decides in cycles if and for how long the complete purge air volume is to be supplied in order to

achieve and stabilize the required degree of drying. This process is implemented by means of a cycle-operated solenoid

valve. The time for the two subprocesses described below therefore varies in each cycle, in order to keep the degree of

drying within the specified tolerance range.

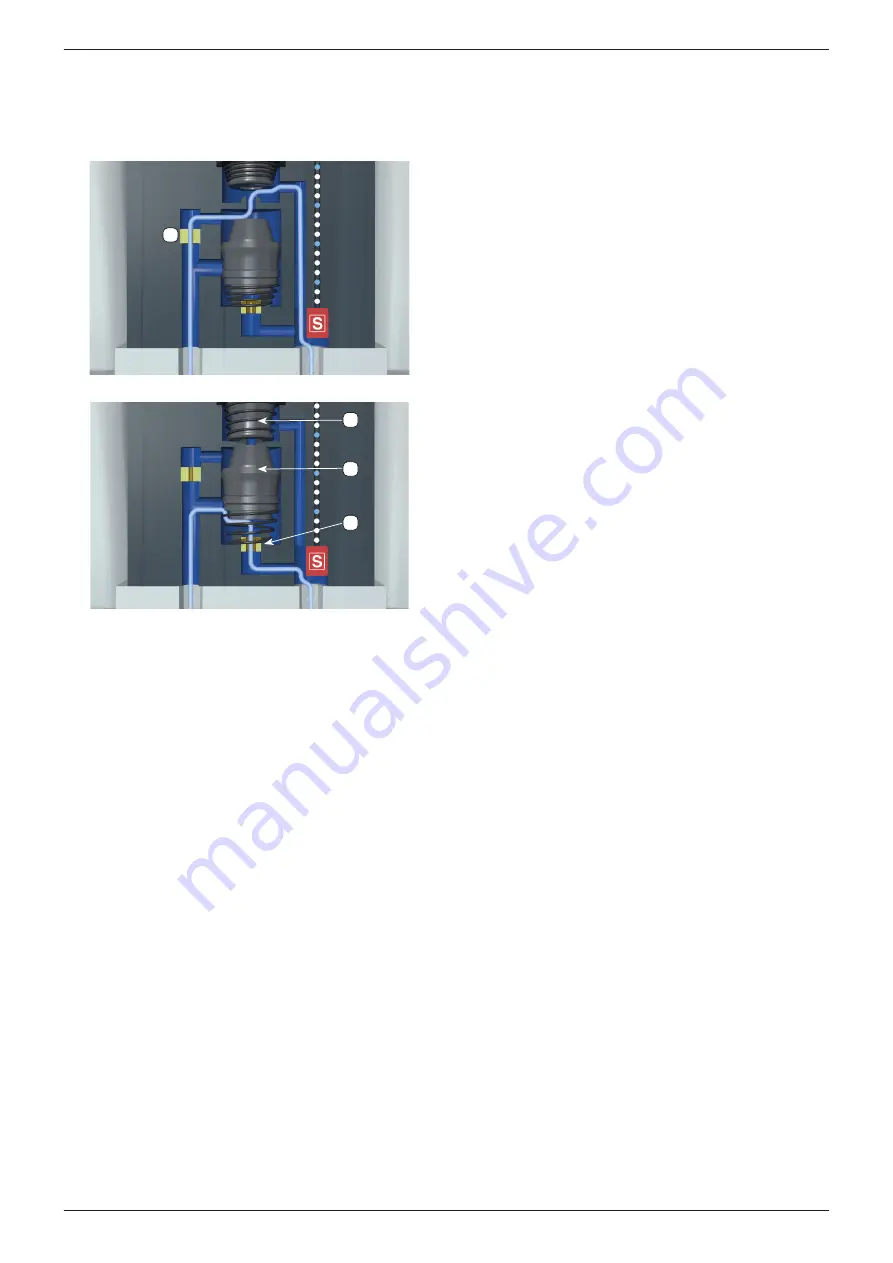

Function: Measuring gas flow

A very small partial flow of the dried compressed air

(measuring gas) flows continuously through the internal

channel along the temperature and humidity sensor (S) to the

measuring gas nozzle (1). This sensor continuously measures

the moisture content of the compressed air in the measuring

gas and sends the result to the control.

Function: Purge air flows

The control continuously compares the measured degree of

drying of the measuring gas with the setpoint value for the

DRYPOINT

®

M intelligence. Tthe valve unit is actuated in

case of deviations: The solenoid core (2) and the piston (3)

close the valve seat so that the compressed air flows through

the purge air nozzle (4) to the membrane dryer. The drying

process commences without delay.

2.3.2. Operating mode

Constant mode (-14 °F; factory-set) -

the pressure dew point at the outlet is kept constant:

In this operating mode, the DRYPOINT

®

M intelligence keeps the set outlet pressure dew point constant b50 and

-15 °F. If the set pressure dew point is less than 10 °F below the compressed air temperature, the setpoint pressure dew

point is automatically reduced by one step (to max. -15 °F). As soon as the difference is again 10 °F, the system returns to

normal operation.

Dynamic mode -

the difference between the compressed air temperature and the outlet pressure dew point is kept

constant:

In this operating mode, the pressure dew point is reduced relative to the compressed air temperature by a specified

difference between 20 and 100 °F. If the compressed air temperature changes, the pressure dew point follows automatically.

For technical reasons, the compressed air temperature increase is limited to 4 °F/h in order to eliminate insignificant short-

term changes in the ambient conditions on site.

1

3

2

4