CLEARPOINT® Flanged L100-L304_us_en_2014-6 (rev. A)

7

The nominal diameter of the pipes should be as uniform as possible in order to avoid creating additional flow resistance.

Reduced pipe sections should only be installed where required for partial-flow outlets (ring, connecting or supply lines).

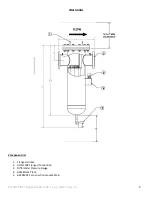

TECHNICAL SPECIFICATIONS OVERVIEW

Model

Pipe Size

ANSI

Flange

Flow

Rate

*)scfm

A

In

B

In

C1

In

C2

In

D

In

Volume

Gallons

Weight

Lbs.

Filter

element

**)

L100

4” FLG

1900

20.25

6.875

76.20

59.50

13.00

10.00

195

88(Typ)2 x

L102

4” FLG

2800

20.25

7.125

60.50

47.50

13.00

16.00

266

88(Typ)3 x

L150

6” FLG

3800

23.50

8.00

60.00

47.00

13.00

17.00

328

88(Typ)4 x

L156

6” FLG

6500

23.75

8.25

64.30

50.00

14.30

26.00

360

88(Typ)7 x

L200

8” FLG

7500

28.00

9.50

67.30

53.00

14.30

32.00

469

88(Typ)8 x

L204

8” FLG

9300

27.95

9.65

67.60

53.30

14.30

44.11

575

88(Typ)10 x

L254

10” FLG

13000

34.65

8.50

69.06

54.76

14.30

70.00

761

88(Typ)14 x

L304

12” FLG

21000

38.95

11.02

74.69

60.39

14.30

107.50

1135

88(Typ)22 x

*)

Volumetric flow at 100 psi operating pressure, related to 68°F (20 °C) and 14.5 psi absolute(1.0 bar).

Validated in accordance with ISO 12500-1, INLET CONCERTRATION 5-15mg/m3

**)

When ordering, please state the required quantity of filter elements and the degree of filtration (type).

***)

Coalescing filter = Residual aerosol content

Activated carbon filter = residual vapor content

Type

Description

Solid Particles

µm

Residual Oil Content

mg/m3 ***)

C

Coarse filter

25

1010

G

General purpose filter

5

5

G

Fine filter

0.1

1

S

Super fine filter

0.01

0.01

A

Activated carbon filter

-

0.003

R (typ)

Dust filter

Type

Type

CORRECTION FACTORS

Operating Pressure

Inlet air pressure psig 20 40 60 80 90 100 120 130 140 160 180 200

Factor

P

1

0.30 .48 .65 .82 .91 1.00 1.17 1.26 1.35 1.52 1.70 1.87

•

For the maxium volume flow, multiply the model volume flow shown in the table by the correction factor

corresponding to the working pressure.