7

5. INSTALLATION

5.1 Location

The BA354ND rate totaliser is housed in a robust

IP66 glass reinforced polyester (GRP) enclosure

incorporating an armoured glass window and

stainless steel fittings. It is suitable for exterior

mounting in most industrial environments,

including off-shore and waste water treatment.

Please consult BEKA associates if high vibration is

anticipated.

The BA354ND enclosure is surface mounting.

Accessory kits described in sections 9.5 & 9.6 of

this manual enable the instrument to be mounted

onto a vertical or horizontal pipe, or directly onto a

flowmeter conduit entry.

The field terminals and the two mounting holes are

located in a separate compartment with a sealed

cover allowing the instrument to be installed

without exposing the display assembly.

Terminals 2 and 4 are internally joined and may be

used for linking the return 4/20mA wire - see Fig 2.

Similarly terminals 5 and 6 are internally joined and

may be used for linking the cable screens. The

BA354ND earth terminal is connected to the

internal EMC filters. For maximum radio frequency

interference rejection this terminal should be

connected to a cable screen which is earthed in

the safe area.

To prevent circulating currents,

cable screens should only be earthed at one point

in the safe area.

The BA354ND enclosure is supplied with a

bonding plate to ensure electrical continuity

between the three conduit / cable entries.

5.2 Installation Procedure

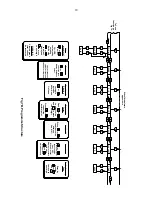

Fig 4 illustrates the instrument installation

procedure.

a.

Remove the instrument terminal cover by

unscrewing the two captive 'A' screws.

b.

Mount the instrument on a flat surface and

secure with two M6 screws through the 'B'

holes. Alternatively use one of the mounting

kits described in section 9.5

c.

Remove the temporary dust seals from the

three cable entries and install the required

glands, conduit fittings or blanking plugs. To

comply with the BA354ND ATEX certification

requirements these fittings must be Ex n or

Ex e approved.

Note:

The temporary dust seals do not

provide IP66 protection.

d.

Connect the field wiring to the terminals as

shown in Fig 5.

e. Replace the instrument terminal cover and

evenly tighten the two 'A' screws.

Fig 4 BA354ND installation procedure

5.3 EMC

The BA354ND complies with the requirements of

the European EMC Directive 2004/108/EEC. For

specified immunity all wiring should be in

screened twisted pairs, with the screens earthed

in the safe area.

Additional immunity may be obtained by

connecting the BA354ND earth terminal to a

cable screen which is earthed in the safe area.